Oxygen-acetylene brazing clamp for air filtration

An air filter and acetylene technology, applied in the field of aerospace parts processing, can solve problems such as poor molding consistency, burn-through, and difficulty in tracking welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

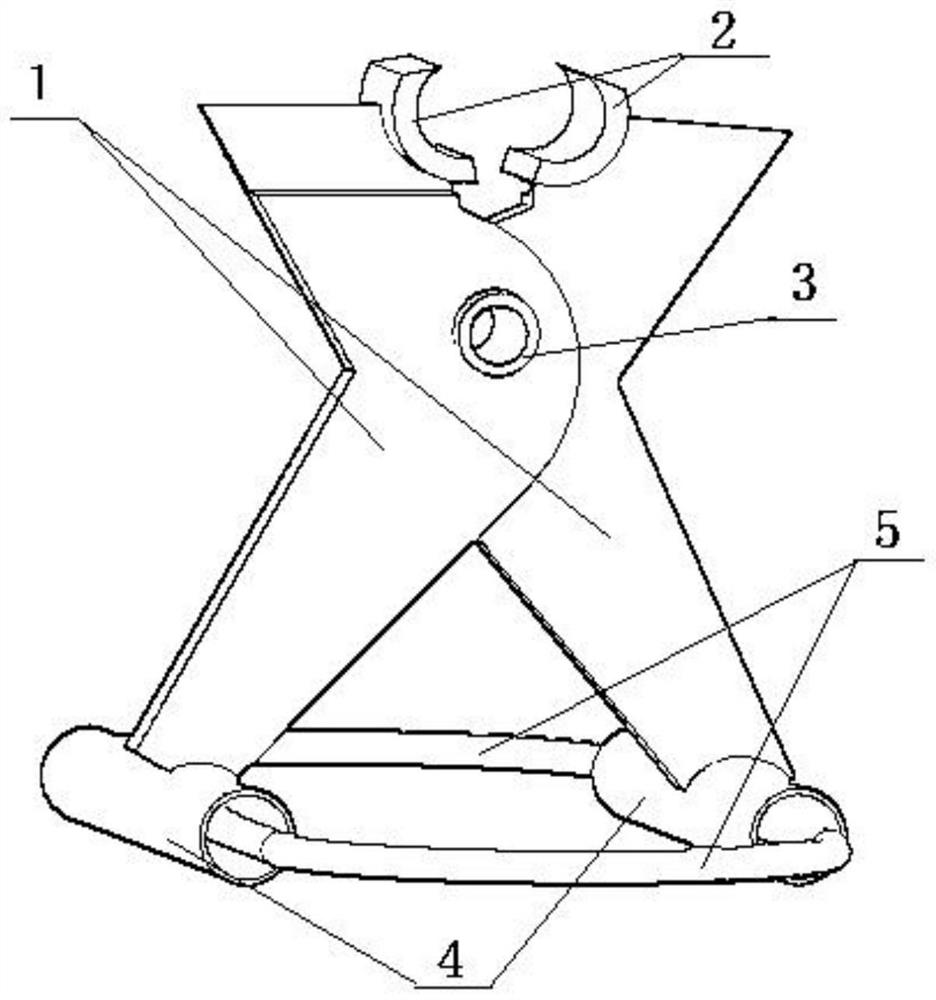

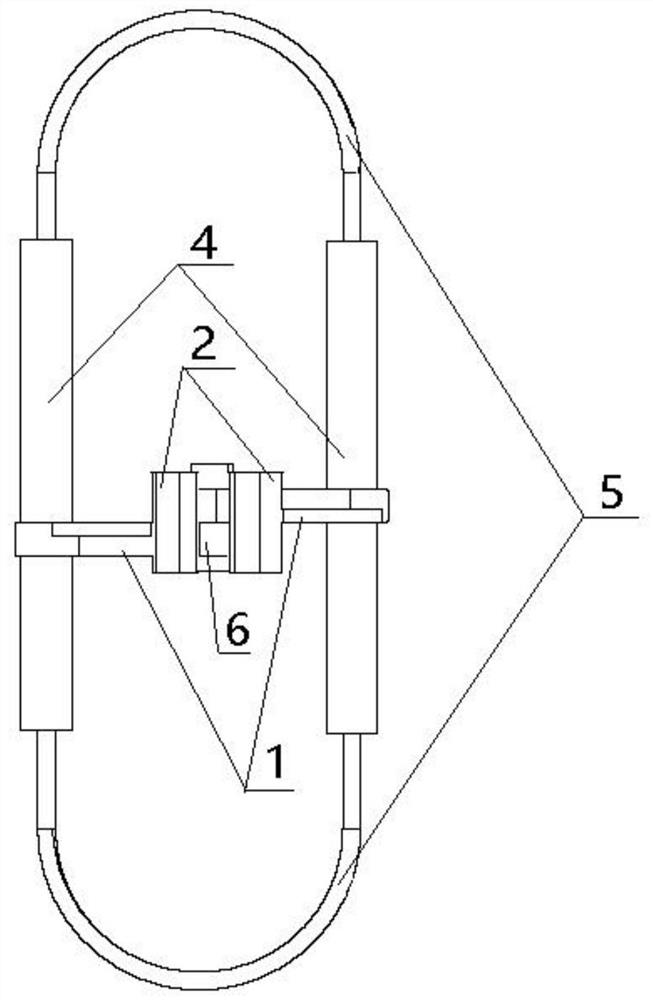

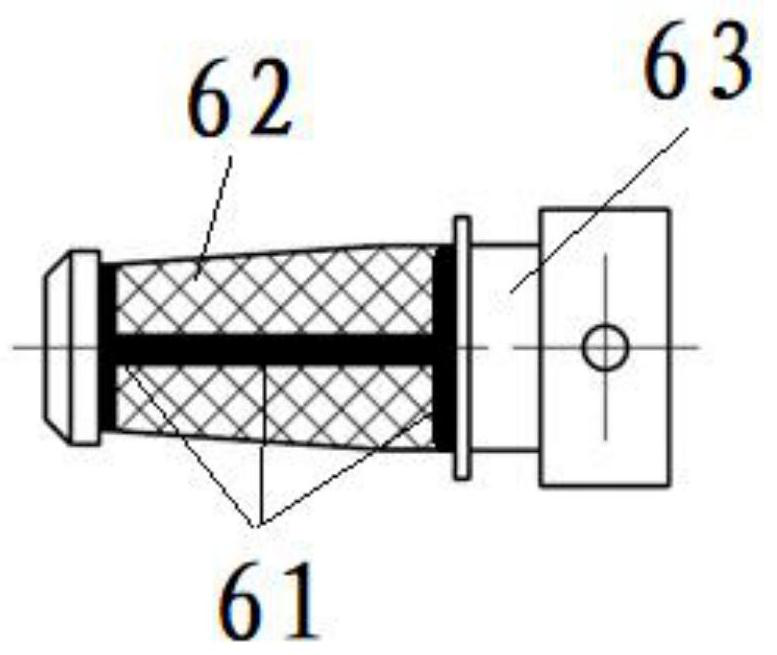

[0021] Such as Figure 1-2 As shown, an oxygen-acetylene brazing fixture for air filter 6 includes a supporting frame 1, a part clamp block 2, a rotating pin 3, a sleeve 4 and an elastic steel wire 5, and there are two supporting frames 1, Cross-connected through the rotating pin shaft 3 from the middle, the two supporting frames 1 can rotate around the rotating pin shaft 3; Two, fixed symmetrically on the lower ends of the two supporting frames 1, and the elastic steel wire 5 is fixedly installed between the two casings 4; when the parts are clamped, the elastic steel wire 5 exerts elastic force on the casing 4, and the supporting frame 1 The part clamping block 2 passed to the upper end clamps the air filter 6. There are two elastic steel wires 5, and the two elastic steel wires 5 are arranged symmetrically at the ends of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com