Aluminum alloy plate strip preparation method based on vacuum centrifugal casting and vacuum centrifugal casting device

A technology of aluminum alloy strips and vacuum centrifugation, which is applied in the field of vacuum centrifugal casting devices and can solve problems such as defects in the structure of aluminum alloy strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

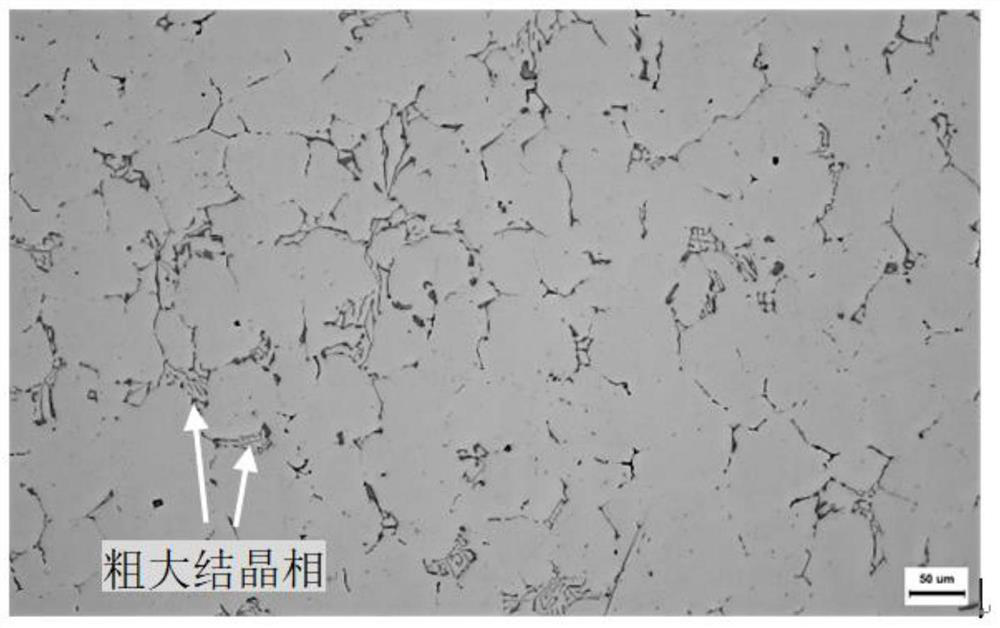

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention proposes for the first time a method for preparing aluminum alloy plates and strips based on vacuum centrifugal casting, which includes the following steps: Step 1: preparing raw materials according to the target aluminum alloy composition;

[0057] Step 2: If Figure 5-6 As shown, the vacuum centrifugal casting device for casting cast billets casts cast billets through vacuum centrifugal casting, and the specific operations are as follows:

[0058] 1) Put the prepared aluminum alloy raw materials into the melting crucible 10 through the feeding device 6 and the feeding hopper 5, the melting crucible 10 is set in the furnace body 1 of the melting furnace, and the furnace body 1 is evacuated to a vacuum degree by using a vacuum system 16 1 to 10 5 Pa; heat the melting crucible 10 to the aluminum alloy melting temperature of 600°C-760°C through the induction coil 2, and keep it warm for 0-1h; cool the melting crucible to the casting temperature of 5...

Embodiment 1

[0072] A preparation method of 2A97 aluminum alloy plate and strip, comprising the steps of:

[0073] Step 1: According to the ratio in Table 1, mix the original:

[0074] Table 1 Raw material ratio of 2A97 aluminum alloy (mass percentage)

[0075]

[0076] Step Two: Adopt Figure 5 or Figure 6 The device in the device casts 2A97 aluminum alloy tube blanks by means of vacuum centrifugal casting, and the specific operations are as follows:

[0077] 1) Put the prepared aluminum alloy raw materials into the melting crucible, and vacuumize the furnace body until the vacuum degree is 1Pa;

[0078] 2) Heat the melting crucible to 740°C; turn on the mold rotation motor and adjust it to 800 rpm;

[0079] 3) Cool down the melting crucible to 680°C, and pour the aluminum alloy liquid in the crucible into the rotating billet mold;

[0080] 4) After the aluminum alloy liquid in the mold of the aluminum alloy plate and strip is completely solidified, stop the rotation of the cast ...

Embodiment 2

[0094] A preparation method of 7055 aluminum alloy plate and strip, comprising the steps of:

[0095] Step 1: According to the ratio of Table 4, the original ratio:

[0096] Table 4 Raw material ratio of 7055 aluminum alloy (mass percentage)

[0097]

[0098] Step Two: Adopt Figure 5 or Figure 6 The device in the method casts 7055 aluminum alloy blanks by vacuum centrifugal casting, and the specific operations are as follows:

[0099] 1) Put the prepared aluminum alloy raw materials into the melting crucible, and vacuumize the furnace body until the vacuum degree is 1Pa;

[0100] 2) Heat the melting crucible to 740°C; turn on the mold rotation motor and adjust it to 800 rpm;

[0101] 3) Cool down the melting crucible to 680°C, and pour the aluminum alloy liquid in the crucible into the rotating billet mold;

[0102] 4) After the aluminum alloy liquid in the mold of the aluminum alloy plate and strip is completely solidified, stop the rotation of the cast tube billet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com