High-pressure reaction kettle with magnetic stirring function for organic reaction

A high-pressure reaction kettle and magnetic stirring technology, which can be used in mixers with rotating stirring devices, pressure vessels used in chemical processes, and methods for chemically changing substances by using atmospheric pressure, which can solve high-risk problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

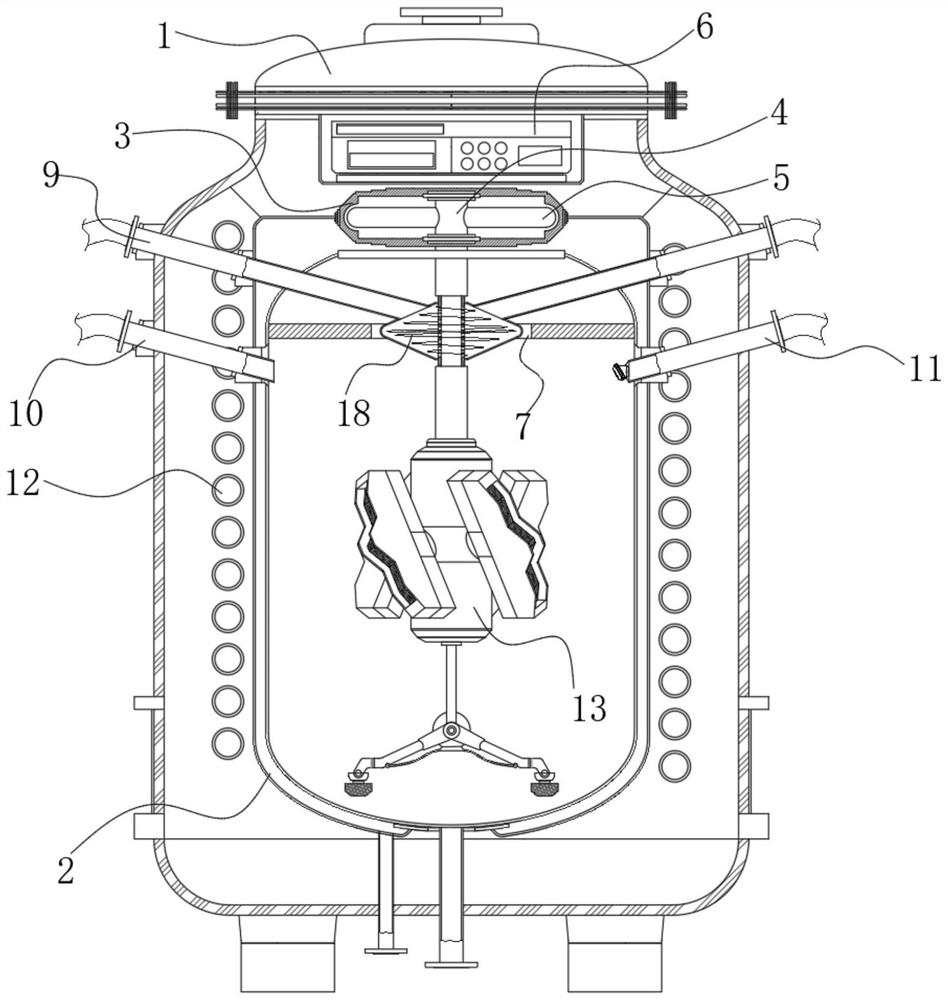

[0036] refer to figure 1 , the present invention provides a technical solution: a high-pressure reactor with magnetic stirring function for organic reactions, which includes a reaction tank 2, a stirring shaft 4, a magnetic stirrer 6, a magnetic rotor 5, a catheter 9, a solid feed Pipe 10 and stirring device 13, the reaction tank 2 is arranged inside the reaction kettle 1, and a heating pipe 12 is spirally wound on the outside of the reaction tank 2, a chrome plating box 3 is fixed on the upper end of the reaction tank 2, and the stirring shaft 4 The upper end is embedded in the interior of the chrome-plated box 3 and is connected to its shell wall bearing, and the stirring shaft 4 is a hollow shaft shell. The magnetic rotor 5 runs through the top shaft body of the stirring shaft 4 transversely and is arranged inside the chrome-plated box 3. Above the chrome-plated box 3 A magnetic stirrer 6 is provided to drive the magnetic rotor 5 to rotate horizontally;

[0037] A mixing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com