Axial driving mechanism, automatic injection device and use method of automatic injection device

An axial drive, sliding groove technology, applied in the direction of automatic injectors, syringes, hypodermic instruments, etc., can solve problems such as violation of ergonomics, the product cannot be guaranteed to self-lock after the product, and the patient forgets to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

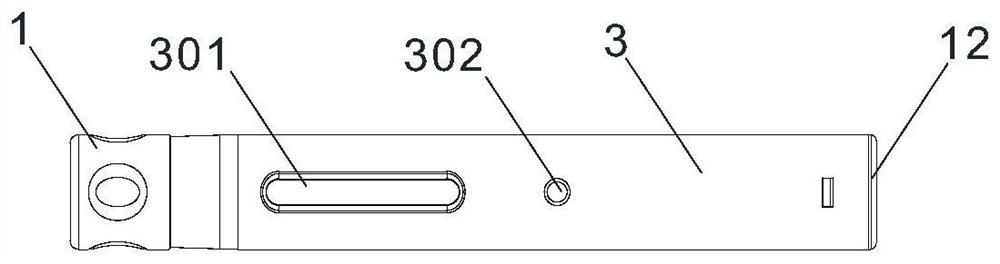

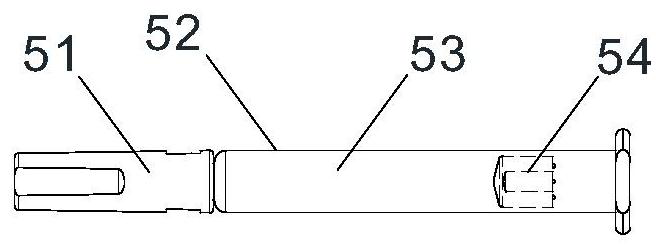

[0086] Such as Figure 1 to Figure 6b , Figure 7a to Figure 17 As shown, an automatic injection device with double visual feedback, including a head-end protective cap 1, a safety sleeve 2, a housing 3, a protective case 4, a prefilled syringe 5, a return spring 6, a release sleeve 7, a limit position Sounding ring 8, guide sleeve 9, push rod 10, injection spring 11 and bottom cover 12, injection spring 11 is provided between push rod 10 and bottom cover 12, head end protective cap 1, safety sleeve 2, shell 3 and protection The shell 4 constitutes the shell assembly, the return spring 6, the release sleeve 7, the limit sounding ring 8, the guide sleeve 9, the push rod 10 and the bottom cover 12 constitute an axial drive mechanism with visual feedback. The front end of the push rod 10, That is, the end facing the prefilled syringe 5 is the output end of the axial drive mechanism, and the prefilled syringe 5 and the axial drive mechanism are arranged in the cavity of the housi...

Embodiment 2

[0097] Such as Figure 6c As shown, the front end of the push rod 10 is equipped with a gasket 1004 that can rotate around the axis of the push rod 10. The gasket 1004 plays the role of a plane bearing. When the push rod 10 is pushed forward, the gasket 1004 contacts the piston 54, and the two maintain Relatively stationary, the push rod 10 and the piston 54 rotate relative to each other, which can reduce the resistance encountered during the rotation of the push rod. All the other are with embodiment 1.

Embodiment 3

[0099] Such as Figures 18 to 20d As shown, the tile-shaped long cantilever is provided with a hollow area, the hollow area is provided with a safety sleeve self-locking cantilever 203, and the safety sleeve self-locking cantilever 203 is provided with a self-locking bump 204, and the self-locking structure is set On the housing assembly, the self-locking structure includes a safety sleeve self-locking cantilever 203 provided on the safety sleeve 2 and a lock block 304 provided on the inner wall of the housing 3, and the lock block 304 protrudes radially on the inner wall of the housing 3 , the lock block 304 is V-shaped as a whole, and the lock block 304 is provided with a starting side wall 3041 and a reset side wall 3042 intersecting at the rear end of the lock block 304, and the starting side wall 3041 and the reset side wall 3042 intersect to form a rear sharp point 3045 of the lock block, The front end of the locking block 304 is provided with a V-shaped groove 3043 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com