Centrifugal compressor rotor capable of hydraulically assembling and disassembling impeller and impeller assembling and disassembling method

A technology for centrifugal compressors and impellers, applied in liquid fuel engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as poor repeat assembly accuracy, safety risks, and rotor appearance deterioration. Achieve the effect of avoiding impeller deformation, avoiding damage and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention is applicable to rotors with single-stage, two-stage back-to-back, two-stage parallel arrangement and other structures.

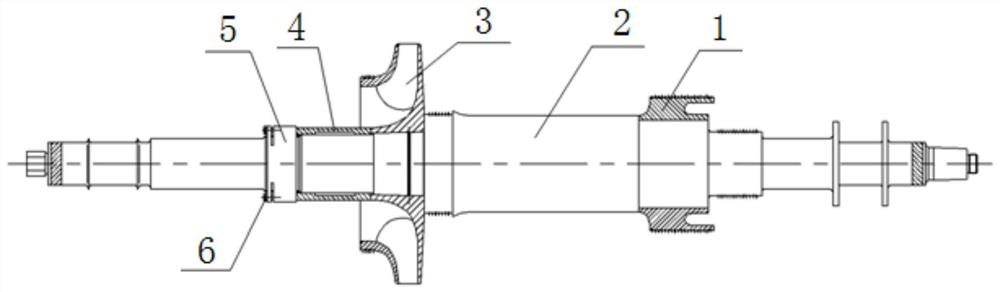

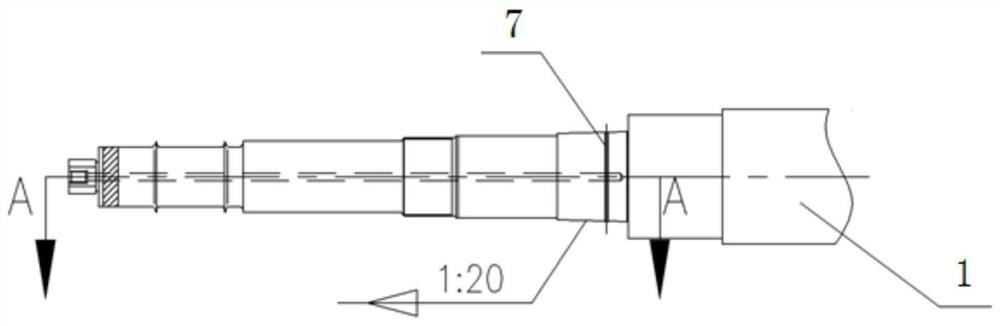

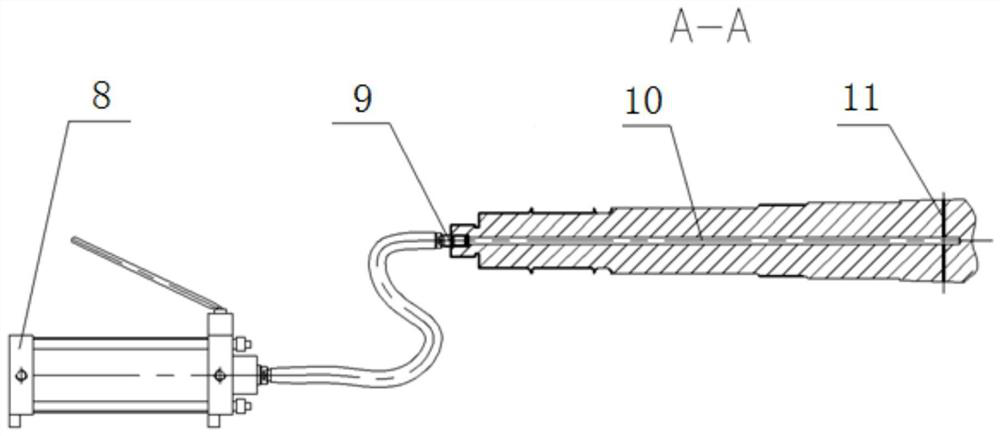

[0032] Such as Figure 1-Figure 3 As shown, the centrifugal compressor rotor of the present invention, which can hydraulically assemble and disassemble the impeller, includes a main shaft 1 , a balance disc 2 , an impeller 3 , a shaft sleeve 4 and a lock nut 5 . Among them, the balance plate 2, the impeller 3, the shaft sleeve 4 and the lock nut 5 are installed on the main shaft 1 in sequence, and the lock nut 5 is connected with the main shaft 1 through threads; the inner hole of the impeller 3 is a conical surface, and the impeller 3 is set on the main shaft , the cone surface of the inner hole of the impeller 3 and the cone surface of the outer wall of the main shaft 1 are interference fit, and the degree of interference is checked and determined according to the rotating speed and the structure of the impeller; the matching cone sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com