Air compressor with noise reduction function

An air compressor and noise reduction technology, applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as single function, poor noise reduction effect, and inability to achieve comprehensive noise reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

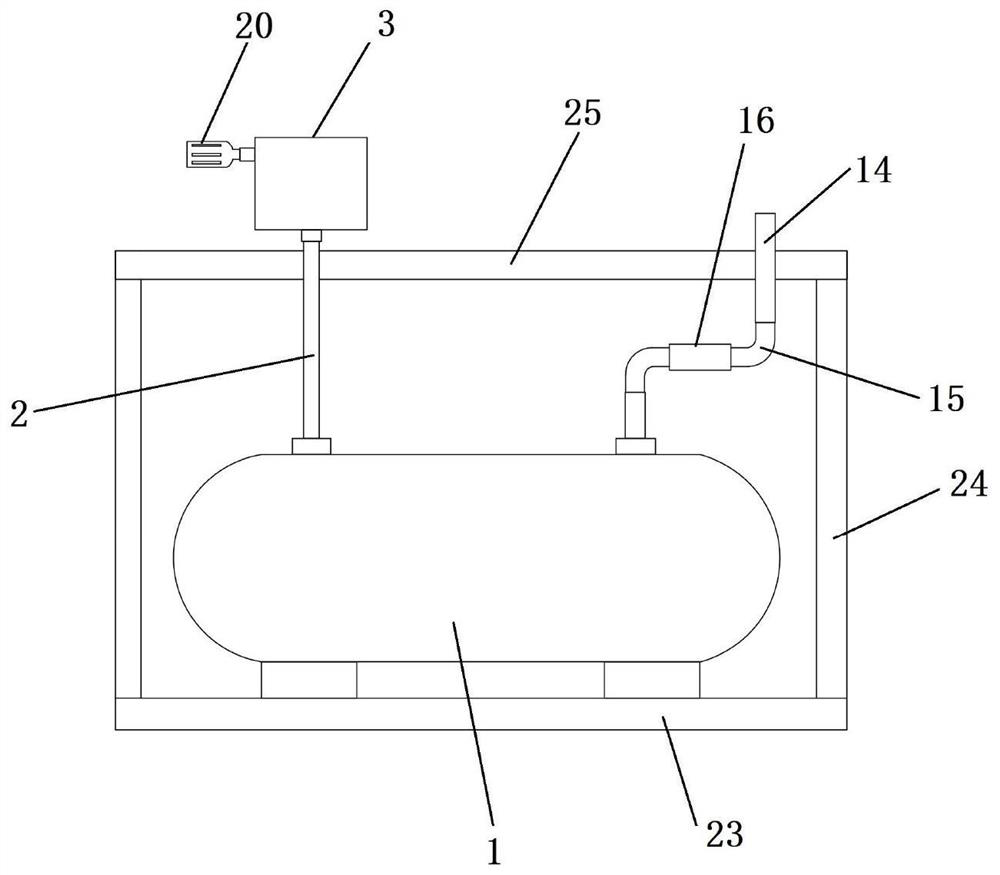

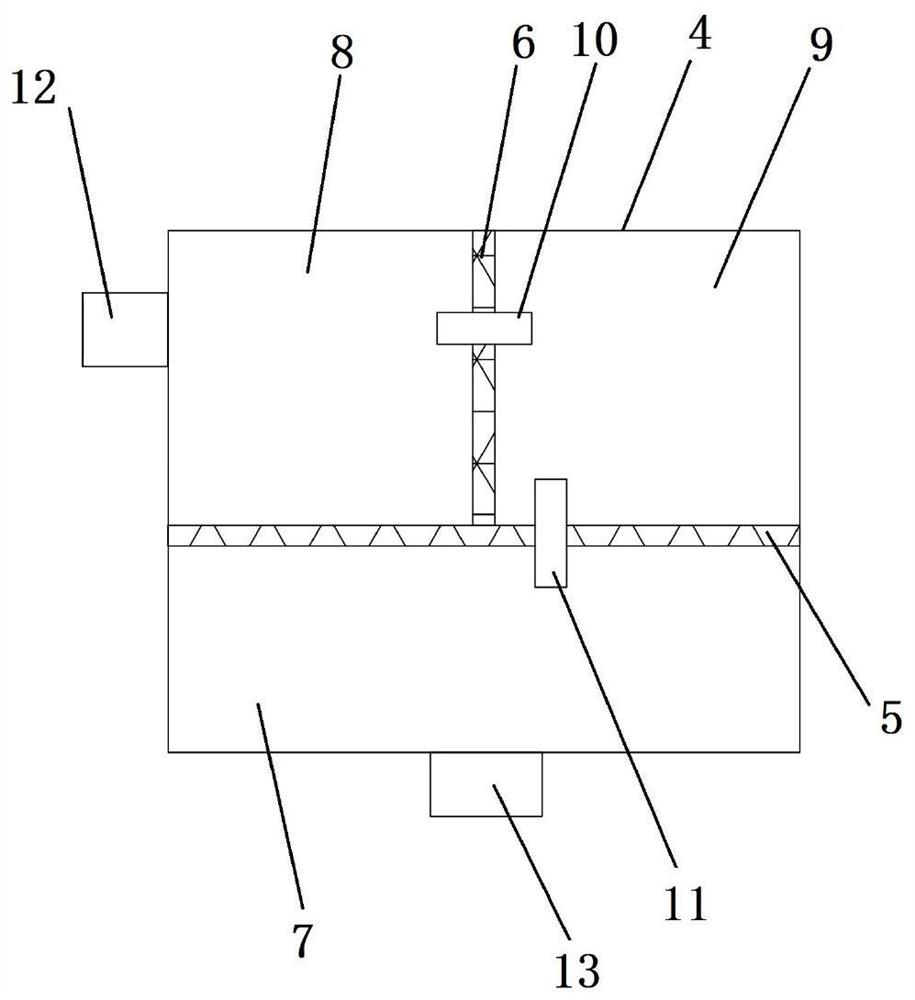

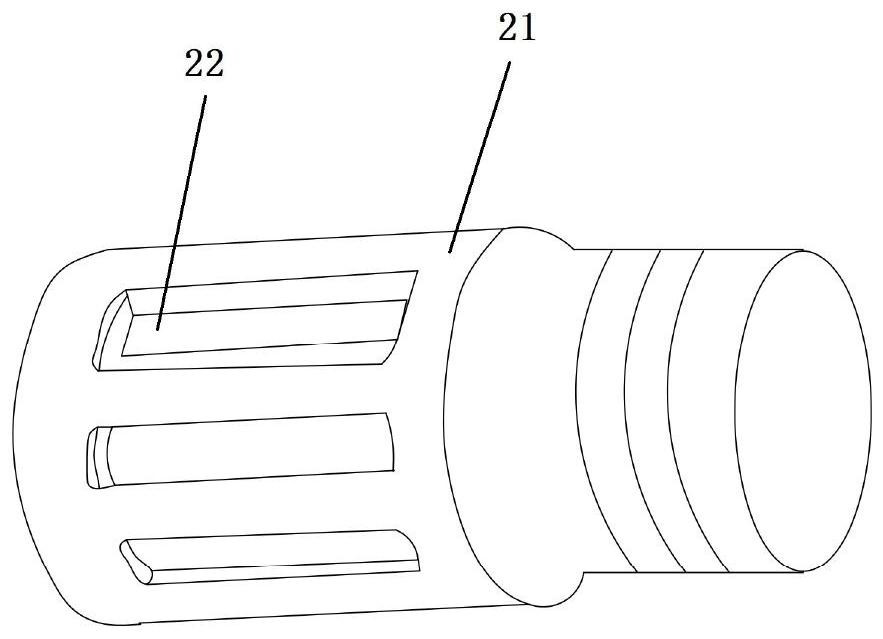

[0027] The embodiment of the present invention discloses an air compressor with noise elimination and noise reduction functions, such as figure 1 As shown, it includes a noise reduction bottom plate 23, a plurality of noise reduction side plates 24, a noise reduction top plate 25, and an air compressor main body 1. The air compressor main body 1 is fixedly arranged on the noise reduction bottom plate 23, and a plurality of noise reduction side plates 24 surround It is arranged outside the main body 1 of the air compressor, and the noise-reduction top plate 25 is fixedly arranged on the side of the noise-reduction side plate 24 away from the noise-reduction bottom plate 23 . Gas muffler 3, the other side of the main body of the air compressor 1 is connected with an air outlet pipe 14, and an air outlet muffler 16 is installed on the air outlet pipe 14. Both the upper ends of the air inlet pipe 2 and the air outlet pipe 14 run through the noise reduction top plate 25 and extend t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com