Closed gas well drainage pry

A closed, gas well technology, applied in the directions of sealing/isolation, wellbore/well components, production fluid, etc., can solve the problem of unexpected blowout without setting up gas wells, and achieve strong construction continuity, high pumping efficiency and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

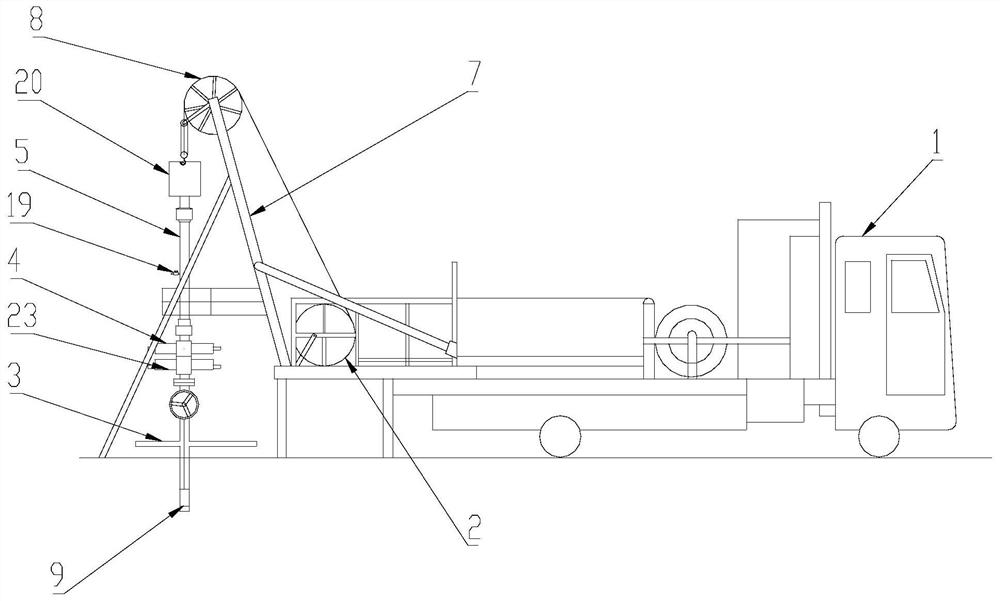

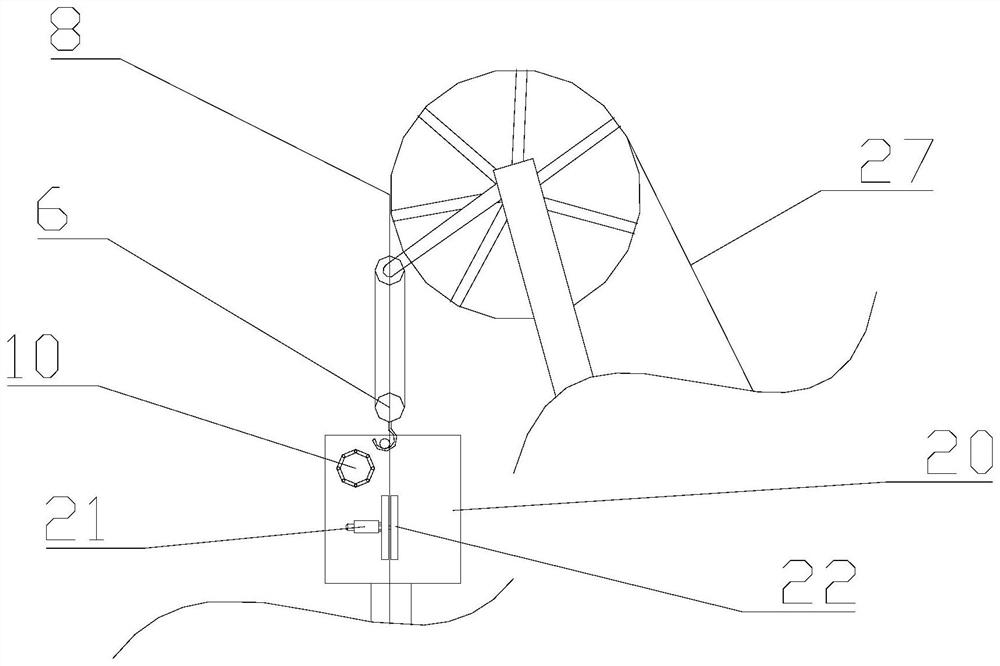

[0024] Such as Figure 1-4 As shown, a closed type gas well drainage skid includes an operation vehicle 1, and the operation vehicle 1 is provided with a steel wire pulley 2, and includes a gas tree 3, and the top of the gas tree 3 is connected to a blowout preventer 4 to prevent Nozzle 5, a steel wire sealing plug is arranged near the top in the described blowout preventer 5, and the described blowout preventer 5 is suspended on the work vehicle lever 7 of the work vehicle 1 through the pulley block 6, and the work vehicle dials The top of the rod 7 is provided with a sky pulley 8, and the steel wire 27 on the steel wire ground pulley 2 bypasses the sky pulley 8 and penetrates from the top of the blowout preventer 5 to the lower end of the gas tree 3 to connect the drawer 9. Hydraulic blowout prevention scissors 23 are also provided between the blowout preventer 5 and the gas tree 3 .

[0025] In this embodiment, when in use, the lower end of the X-mas tree 3 is inserted int...

Embodiment 2

[0027] Such as Figure 1-4 As shown, a closed type gas well drainage skid includes an operation vehicle 1, which is provided with a steel wire pulley 2, and also includes a gas tree 3, the top of which is connected through a blowout preventer 4. The blowout preventer 5 is provided with a steel wire sealing plug near the top end of the blowout preventer 5, and the blowout preventer 5 is suspended on the work vehicle lever 7 of the work vehicle 1 through a pulley block 6, and the work vehicle The top of the driving rod 7 is provided with a sky pulley 8, and the steel wire 27 with a diameter of 8 mm on the steel wire ground pulley 2 bypasses the sky pulley 8 and penetrates from the top of the blowout preventer 5 to the lower end of the gas tree 3 to connect the drawer. 9.

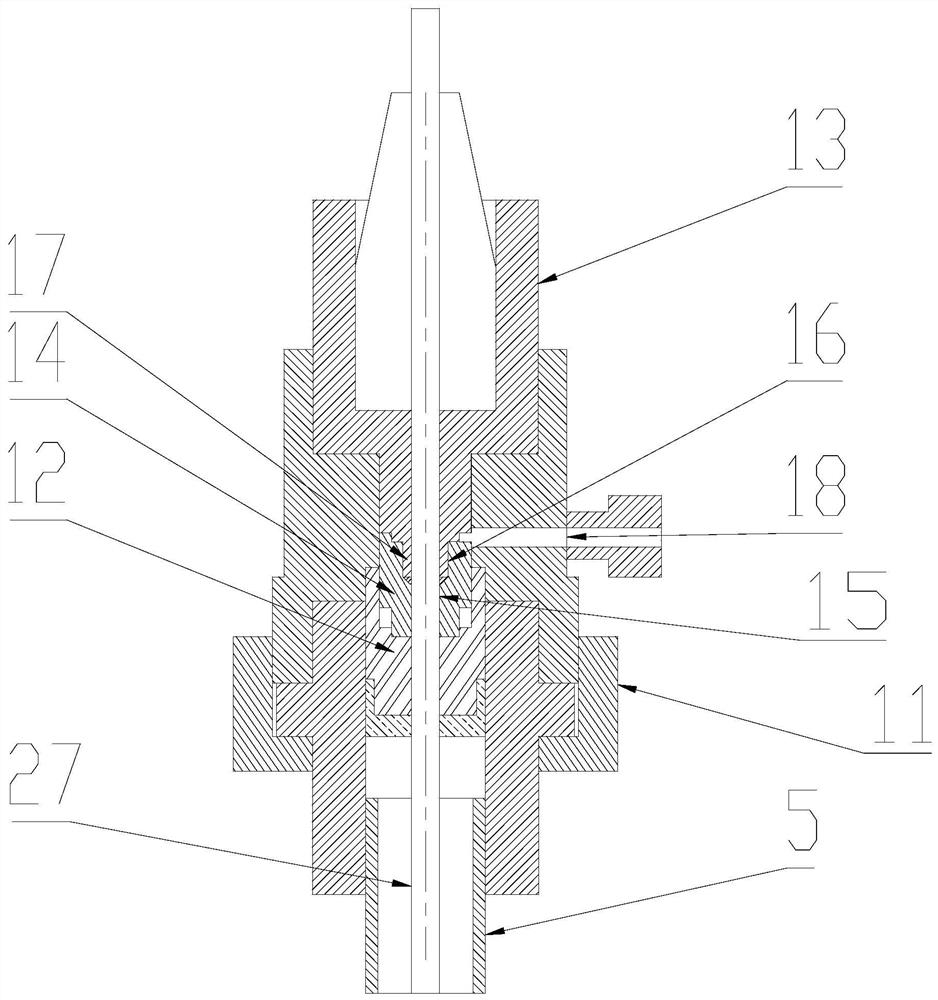

[0028] Wherein, the steel wire sealing plug is composed of a packing sleeve 11, a packing 12 located in the packing sleeve 11, a cylinder liner 13, and a piston 14 matched with the cylinder liner 13 (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com