Large-space three-dimensional twisted gypsum board wall and construction method thereof

A gypsum board and large space technology, applied to walls, building components, insulation, etc., to achieve the effect of reducing mold making costs, low cost, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Examples see figure 1 As shown, this large-space three-dimensional twisted gypsum board wall includes a three-dimensional twisted steel structure frame 7, and a light steel keel and gypsum board 6 connected to the three-dimensional twisted steel structure frame 7, and the gypsum board 6 is made of GRG Fiberglass plasterboard.

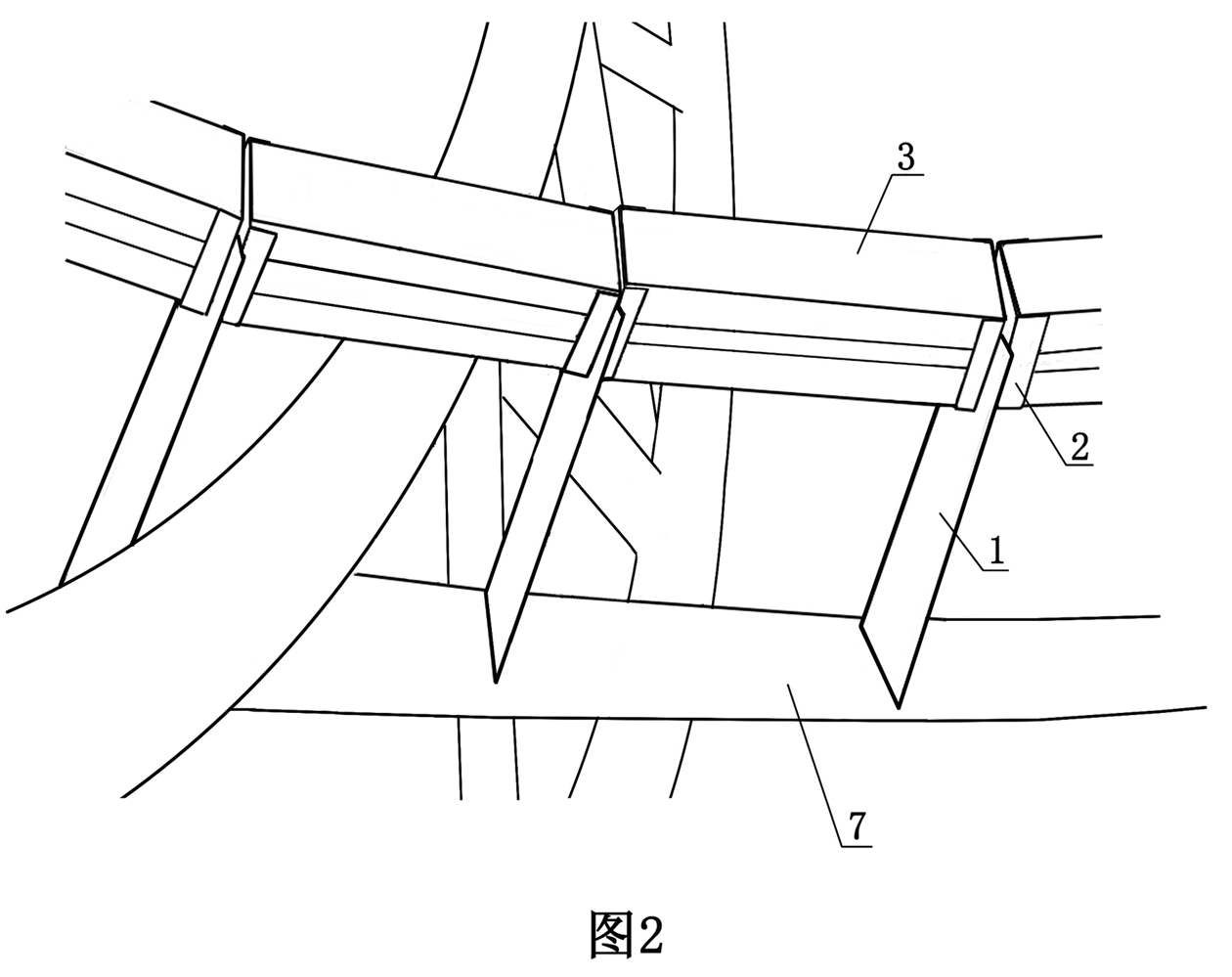

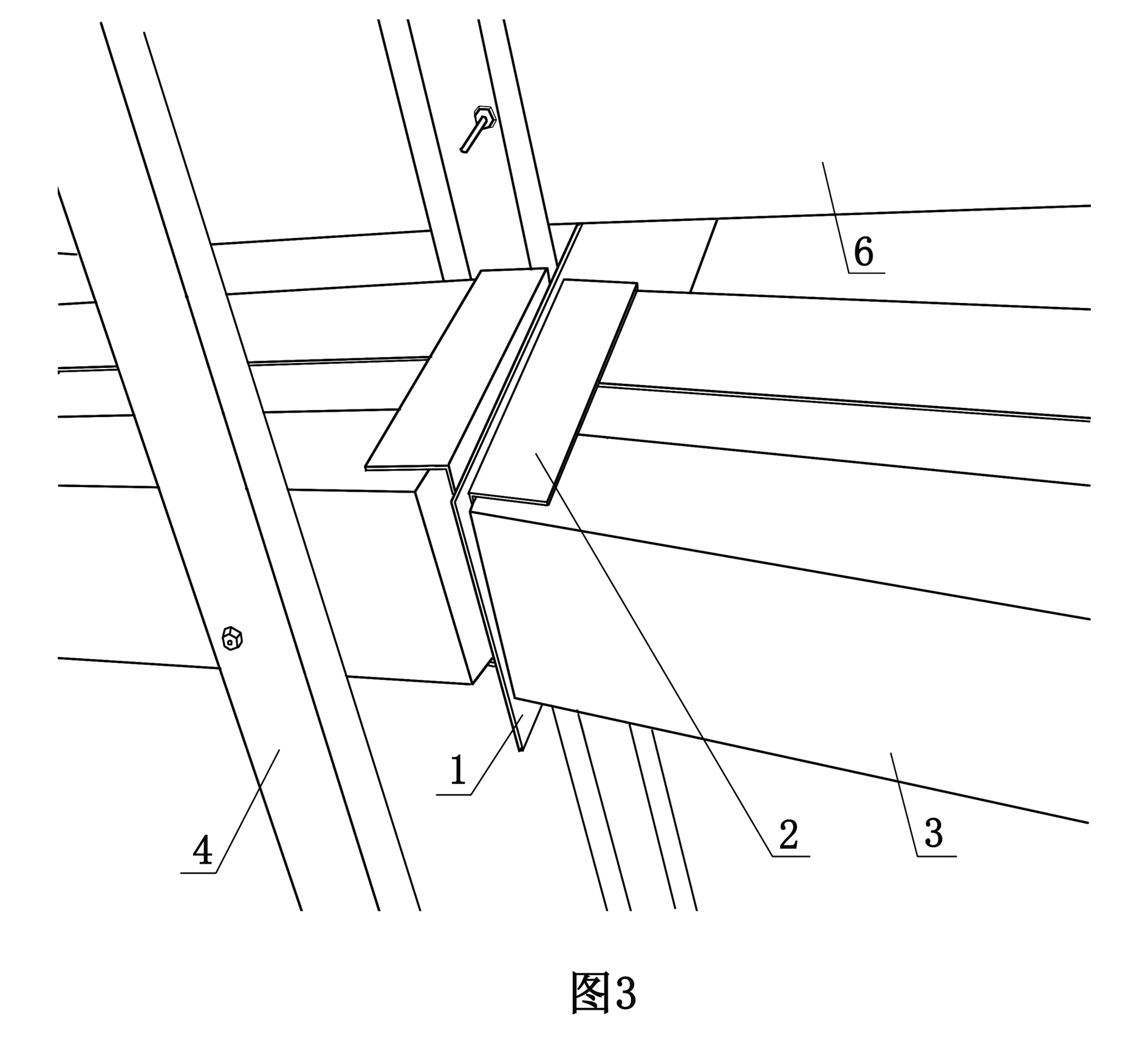

[0031] see figure 2 , image 3 As shown, the short flat steel 1 used to connect the light steel keel is welded at intervals along the horizontal round bar and the longitudinal round bar of the three-dimensional twisted steel structure frame 7. The short flat steel is distributed with bolt holes with a diameter larger than the bolt rod. The light steel keel It is composed of double L-shaped rotatable splints 2, main keel 3 and auxiliary keel 4. The double L-shaped rotatable splints 2 are facing away from each other, and the two sides of the short flat steel are rotatably clamped and connected by bolts respectively; the main keel 3 Each section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com