Construction method of corner compensation for large-diameter and large-curvature pipe jacking

A construction method and technology with large curvature, applied in the direction of pipeline laying and maintenance, pipe/pipe joint/pipe fittings, machinery and equipment, etc., can solve the problems affecting the construction process and construction quality, and the unilateral force between relays is easy to deform and deflect. It can achieve obvious economic and social benefits, short construction period and good airtight performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

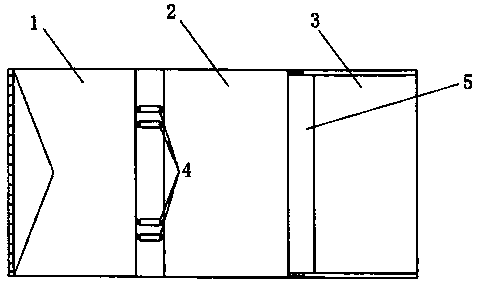

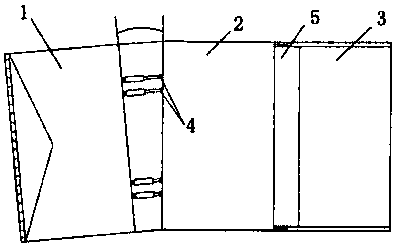

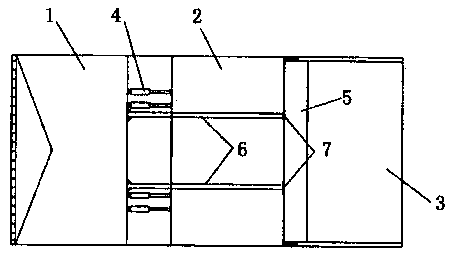

[0032] The construction method of large-diameter and large-curvature pipe jacking angle compensation, the specific steps are as follows:

[0033] 1) Construction preparation: install the guide rail and backrest in the working well, do the work of measurement and lofting before construction, control the elevation of the guide rail and the height of the portal, adjust the position of the backrest steel seal door parallel to the portal, and pour concrete; Preliminarily break the door, and install water-stop flanges and double-layer water-stop rubber rings on the door ring; install internal guide rails in the door to connect with the guide rails in the working well; lift the pipe jacking machine and go down the well and place it on the guide rails. And try to be as close to the hole as possible; install the jack and jack bracket, and fix it with the steel door of the backrest; install the mud discharge system of the pipe jacking machine and the hydraulic system of the jack to furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com