Environment-friendly pipe rod storage and measurement system for well drilling/workover operation

A measuring system and an environment-friendly technology, applied to the automatic control system of drilling, drill pipe, drill pipe, etc., can solve the problems of pipe and pipe discharge, no systematic consideration of workover technology and environmental protection requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and specific embodiment, general scheme of the present invention is described in further detail:

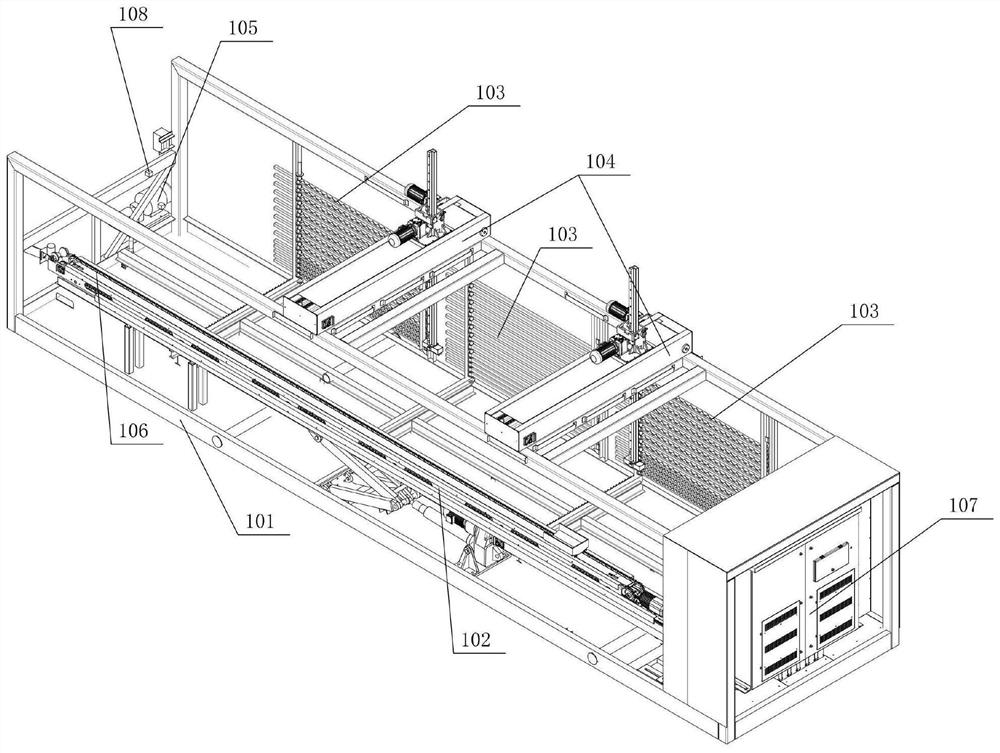

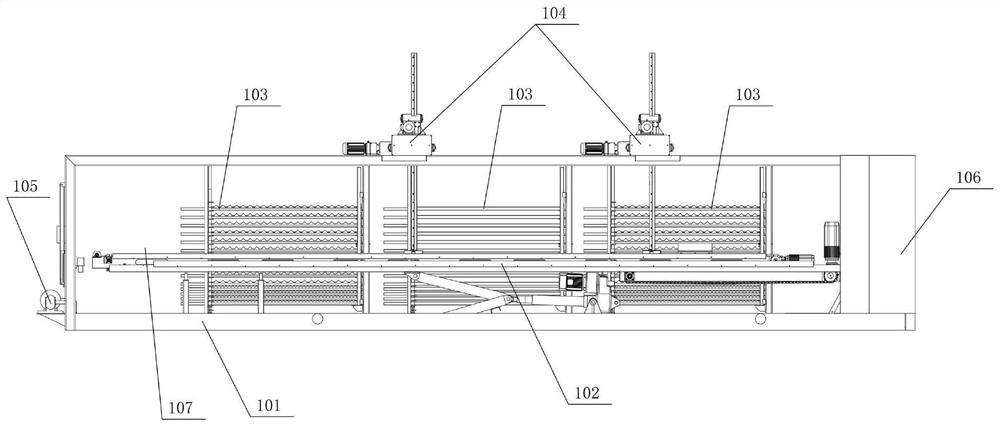

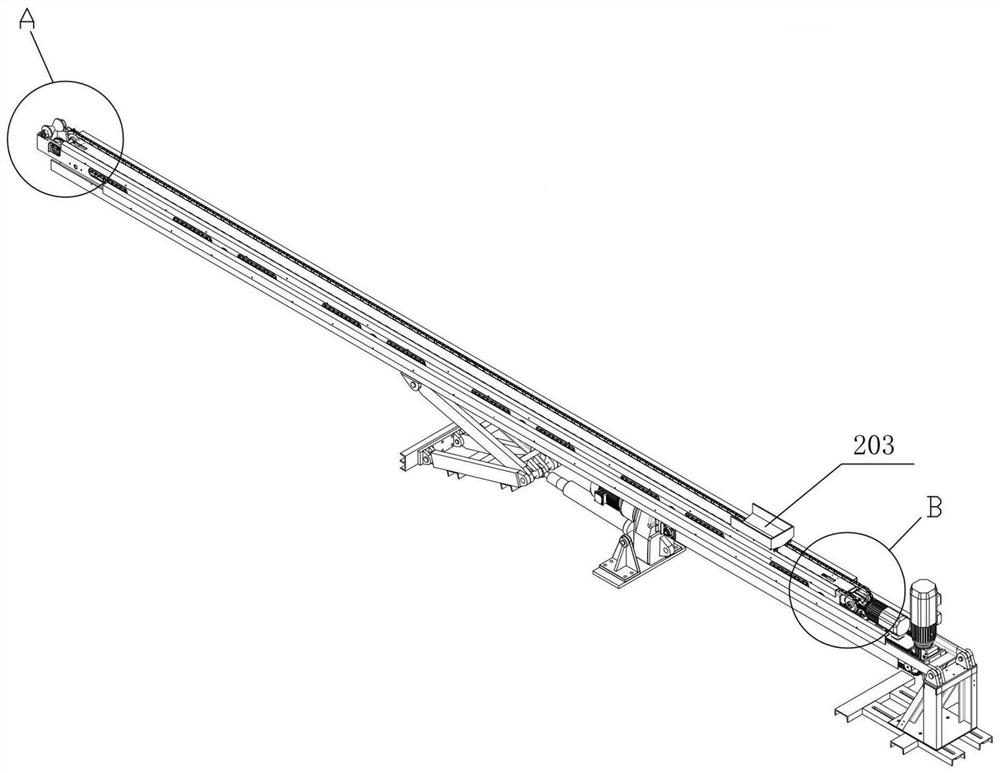

[0055] see figure 1 , 2 , the present invention includes a main pipe box 101, a pipe rod conveying system 102, a rotating layered placement system 103, a pipe rod transfer system 104, an automatic sewage discharge system 105, a pipe rod length measuring system 106, a control system 107 and a cleaning interface 108.

[0056] The pipe and rod conveying system 102, the rotating and layered placement system 103, and the automatic sewage discharge system 105 are all set in the main pipe box 101, the pipe and rod transfer system 104 is set on the upper part of the main pipe box 101, and the pipe and rod length measuring system 106 is embedded in the pipe In the rod conveying system 102 , the control system 107 is installed at the rear end of the main pipe box 101 .

[0057] The main pipe box 101 is welded by section steel, the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com