Preparation method of mixed crystal phase niobium-doped titanium dioxide nanotube array photo-anode

A technology of nanotube array and titanium dioxide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as expensive equipment, high cost of raw materials, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

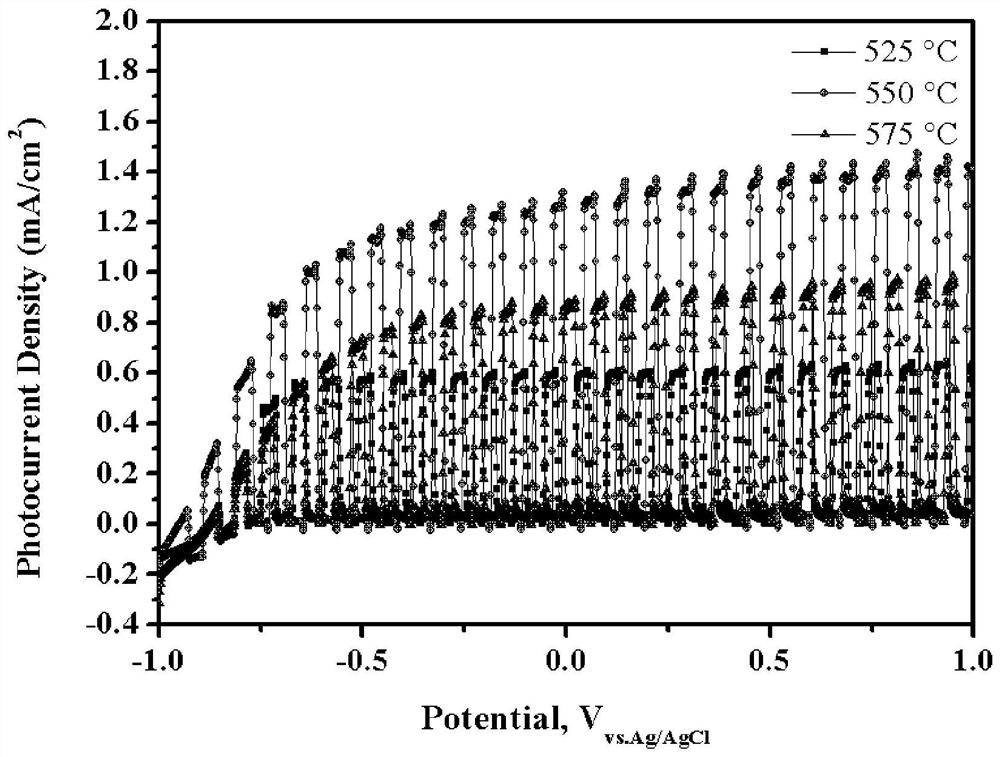

[0024] This embodiment provides a method for preparing a mixed-phase niobium-doped titanium dioxide nanotube array photoanode, which specifically includes the following steps:

[0025] Pretreatment: The Ti-Nb alloy sheet with a size of 10mm×20mm×1mm was polished with 500#, 800#, 1500# and 2000# alumina water sandpaper in sequence until there was no scratch on the surface. Ultrasonic cleaning with deionized water for 5 minutes to remove surface impurities; wherein, the mass fraction of Nb in the Ti-Nb alloy sheet in this embodiment is 1%;

[0026] Anodic oxidation treatment: the pretreated Ti-Nb alloy is used as the anode, the graphite plate is used as the cathode, and 0.4wt% NH 4 F and 2vol%H 2 The ethylene glycol mixed solution of O was used as the electrolyte, and was oxidized under the condition of DC voltage of 40V for 1h, and then the residual impurities on the surface were cleaned with deionized water, N 2 Blowing and drying by air flow to obtain a mixed-phase niobium-...

Embodiment 2

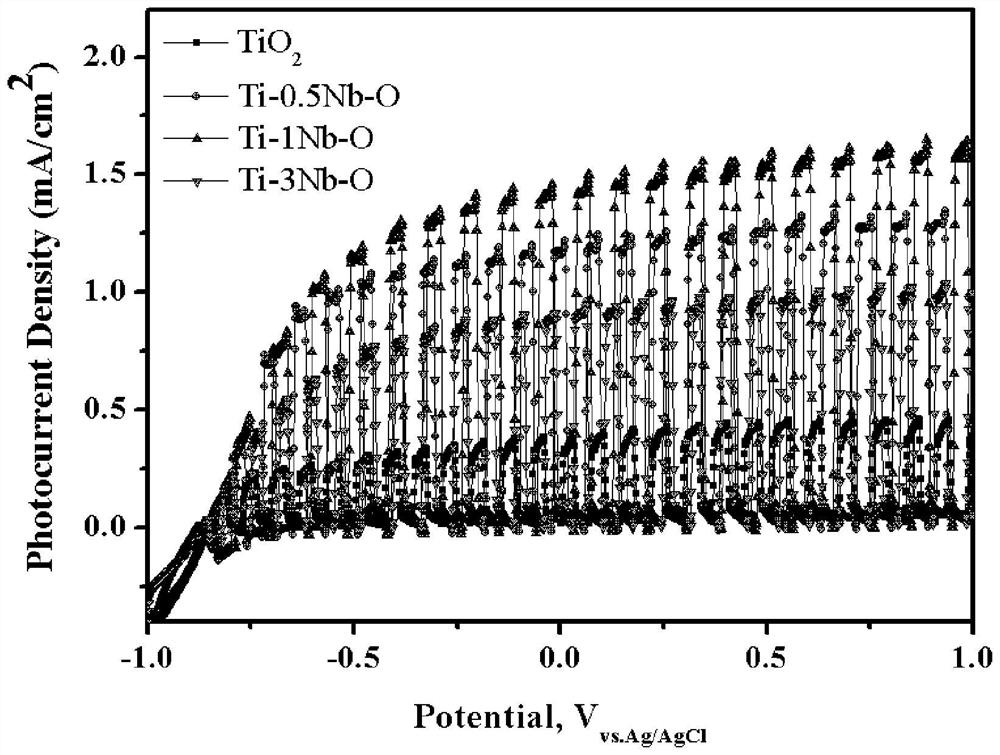

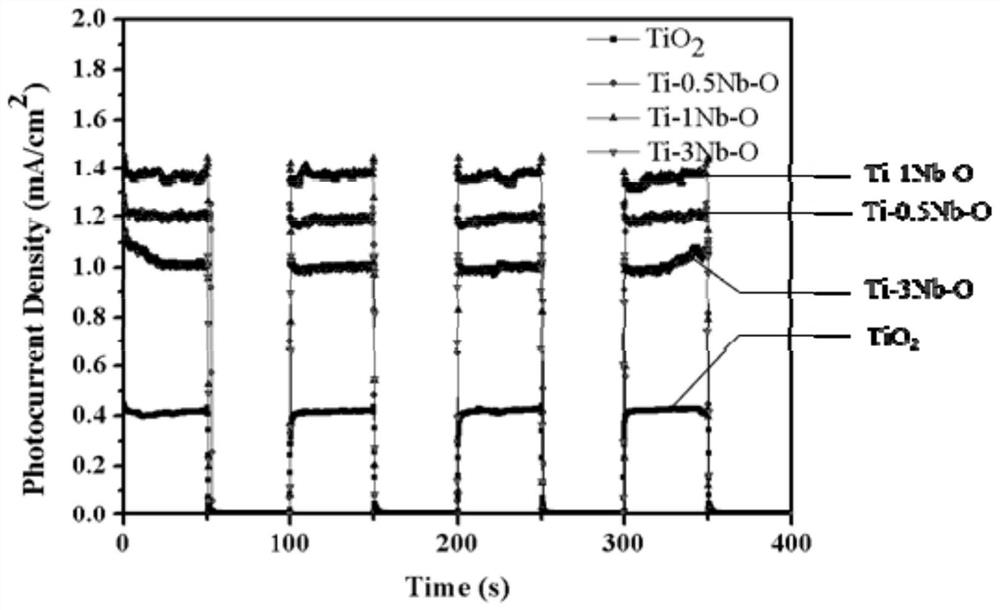

[0030] This embodiment provides a method for preparing a mixed crystal phase niobium-doped titanium dioxide nanotube array photoanode. The difference in the method is that the mass fraction of Nb in the Ti-Nb alloy sheet in this embodiment is 0.5%.

[0031] Among them, the photocurrent density of the mixed crystal phase niobium-doped titanium dioxide nanotube array photoanode obtained in this example is 0.88mA / cm 2 .

Embodiment 3

[0033] This embodiment provides a method for preparing a mixed crystal phase niobium-doped titanium dioxide nanotube array photoanode. The difference in the method is that the mass fraction of Nb in the Ti-Nb alloy sheet in this embodiment is 3%.

[0034] Among them, the photocurrent density of the mixed crystal phase niobium-doped titanium dioxide nanotube array photoanode obtained in this example is 0.94mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com