High-strength and high-toughness magnesium-lithium alloy capable of achieving rapid age hardening and preparation method thereof

A technology of aging strengthening and magnesium-lithium alloys, which is applied in the field of metal materials, can solve problems such as difficulty in large-scale application, poor mechanical properties of magnesium-lithium alloys, and difficulty in meeting mechanical property requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

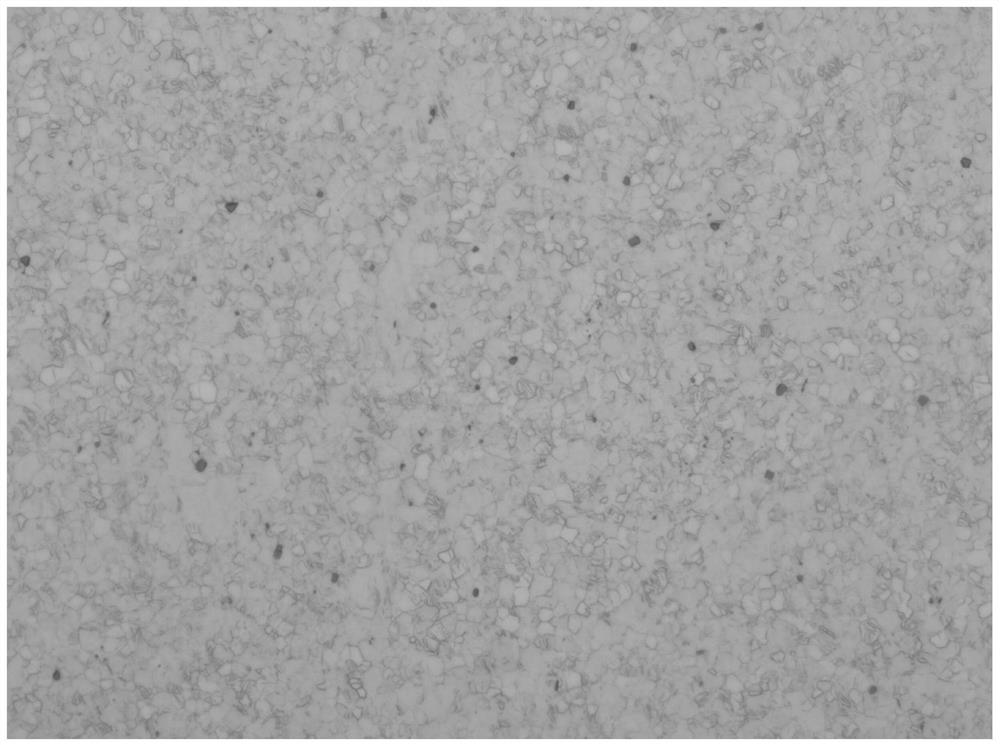

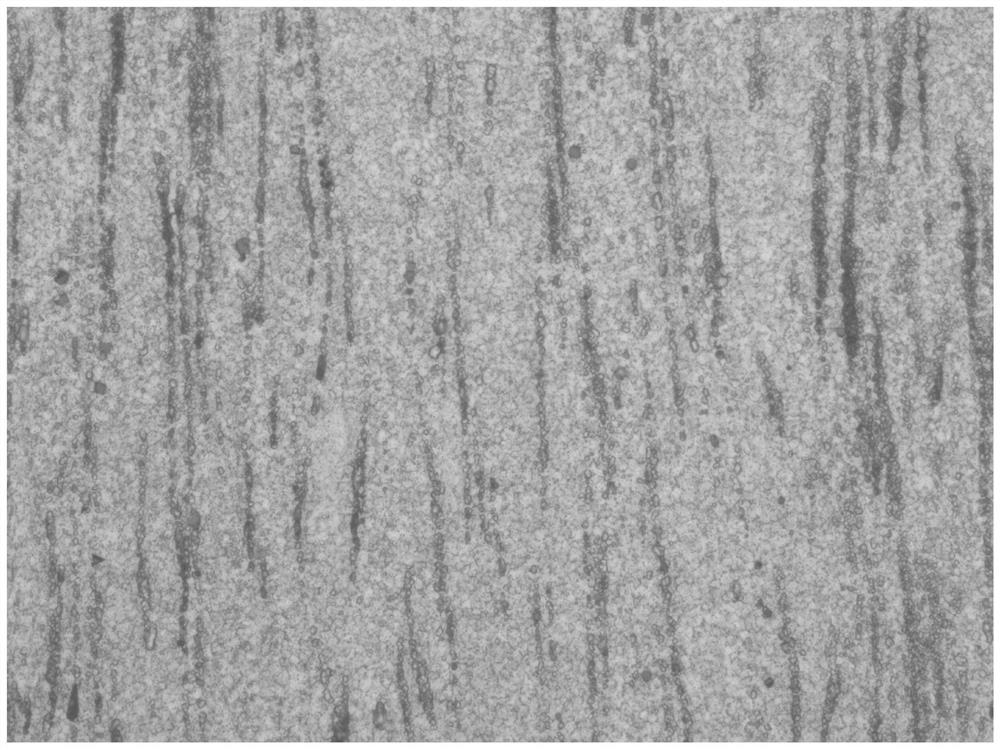

[0030]Select the prepared ingot with the composition of Mg-8Gd-0.1Li, cut it to make a cylindrical ingot with a diameter of 35mm and a height of 34mm, and then carry out solid solution treatment, that is, place the sample in a place protected by argon gas. In the tubular heat treatment furnace, the temperature was raised to 485°C with the furnace, kept for 10 hours, then quenched in boiling water at 100°C, and cooled to room temperature. Then put the solid-solution cylindrical casting billet in the ingot barrel of the press and preheat it for 15 minutes to the extrusion temperature of 385 °C, and then perform hot extrusion deformation treatment at the extrusion speed of 2 mm / s and the extrusion ratio of 10:1 to obtain 12mm diameter bar. The rod was placed in an oil bath at a temperature of 200°C for aging heat treatment, and its age hardening behavior was tested. Finally, it was found that the rod sample reached the peak hardness at 72 hours. The extruded bar and the bar afte...

Embodiment 2

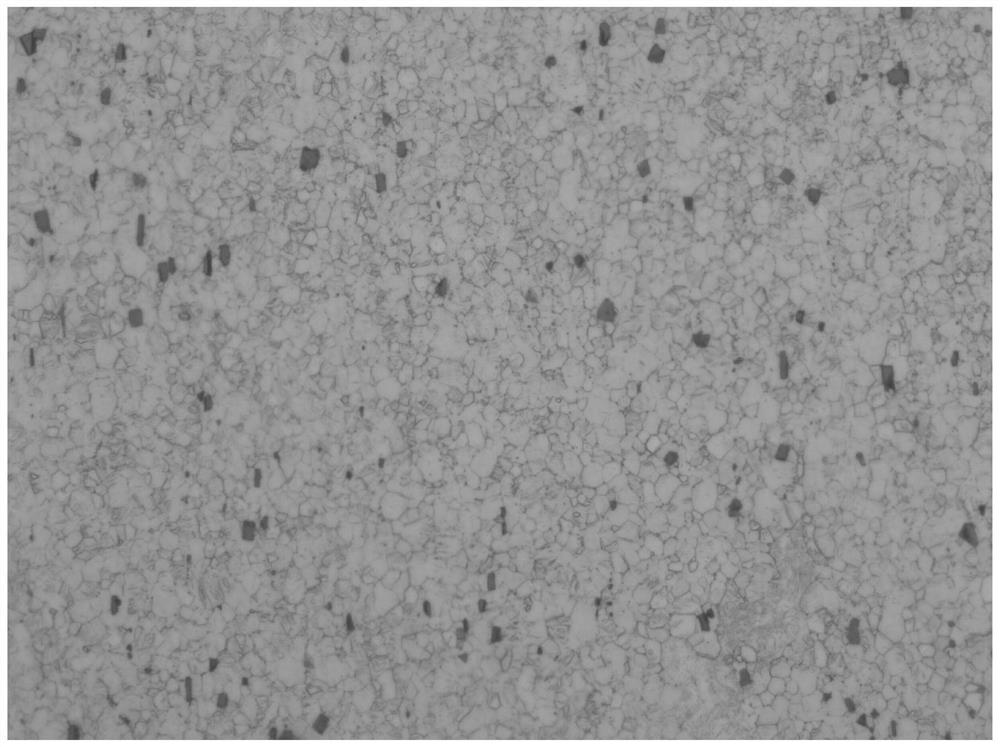

[0032] The procedure is the same as that of Example 1, except that the ingot with the composition of Mg-8Gd-0.5Li is cast, and the peak aging time of the rod at 200° C. is 42 hours. The yield strength, tensile strength and elongation of extruded bars are 180MPa, 247MPa and 20.2%, respectively; while the yield strength, tensile strength and elongation of peak aged bars are 290MPa, 330MPa and 6.0%, respectively.

Embodiment 3

[0034] The procedure is the same as that of Example 1, except that the ingot is cast with the composition of Mg-8Gd-1Li, and the peak aging time of the rod at 200°C is 12h. The yield strength, tensile strength and elongation of extruded bars are 230MPa, 279MPa and 20.0% respectively; while the yield strength, tensile strength and elongation of peak aged bars are 302MPa, 343MPa and 17.5%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com