Viscous bearing release film

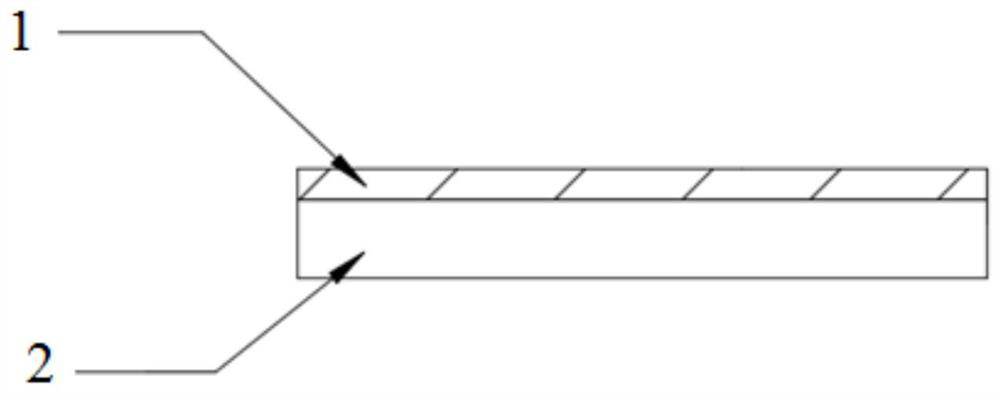

A release film, sticky technology, applied in the direction of film/sheet without carrier, adhesive, film/sheet release liner, etc., can solve the problems of increased cost of bearing release film, low viscosity, delay in manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

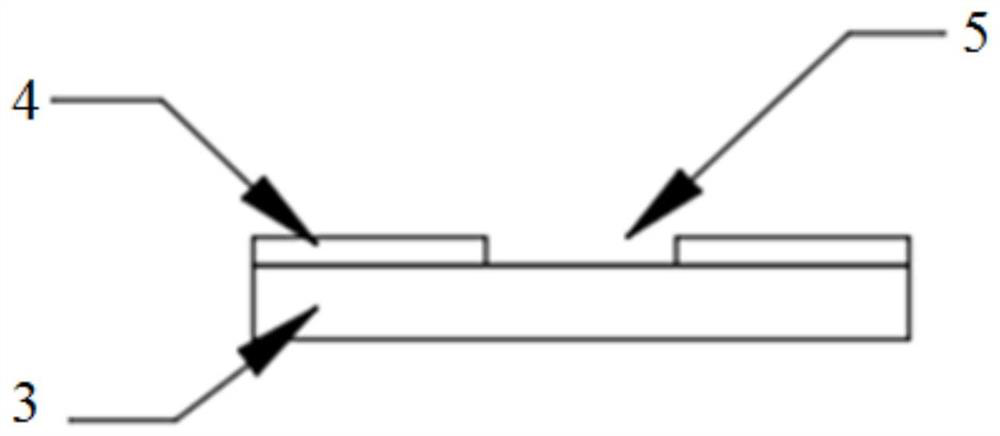

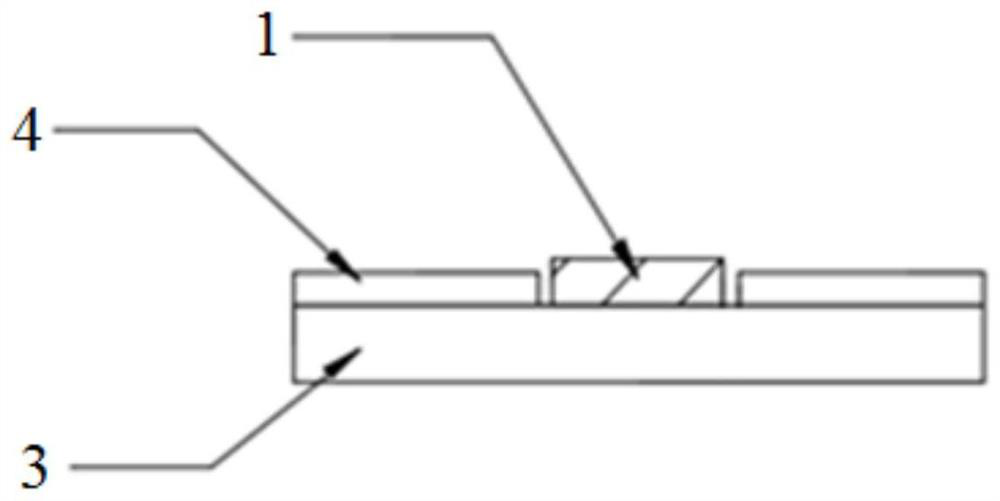

[0027] Such as figure 2 A kind of viscous load-carrying release film shown, comprises viscous base film 3, is located at viscous base film 3 and is the diaphragm 4 of 0.3mm in thickness, and offers the glue area hole 5 on septum 4; Wherein, viscous base film 3 includes a bottom film and a viscous silicone coating on the bottom film. The diaphragm 4 is set on the viscous layer of the viscous bottom film 3. The bottom film is a silica gel bottom film. The viscous coating is a viscous silica gel coating. A gap of 0.25mm is provided between the membrane, the glue area hole 5 and the glue material 1 .

[0028] Working principle: In this embodiment, the low-viscosity load-bearing release film is replaced by the original non-adhesive load-bearing release film to improve the adhesion between the load-bearing release film and the adhesive material 1, and the diaphragm 4 is attached to the sticky bottom during use. On the film 3, wherein, during the attaching process, the non-release ...

Embodiment 2

[0030] In this embodiment, the thickness of the diaphragm 4 is 0.2mm, and the gap between the glue area hole 5 and the rubber material 1 is 0.15mm, and the rest are the same as in the first embodiment.

Embodiment 3

[0032] In this embodiment, the thickness of the diaphragm 4 is 0.15mm, and the gap between the glue area hole 5 and the rubber material 1 is 0.20mm, and the rest are the same as in the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com