A consumable fixing device for 3D printing equipment

A 3D printing and fixing device technology, applied in the field of 3D printing, can solve the problems of consumable loss, irregular surface shape, unstable supply of consumables, etc., and achieve the effect of avoiding loss and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

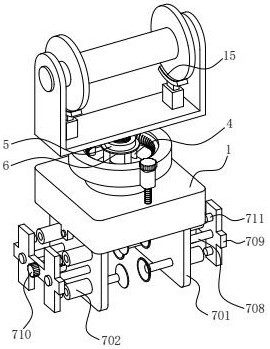

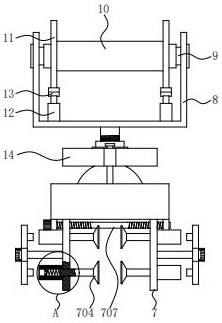

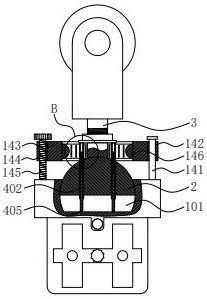

[0030] Such as figure 1 and image 3As shown, this embodiment provides a consumable fixing device for 3D printing equipment, including a mounting base 1, a receiving groove 101 is opened on the top surface of the mounting base 1, and a hemispherical block 2 is installed in the accommodating groove 101, and the surface of the hemispherical block 2 is fixed. A connecting column 3 is installed, and the axis of the connecting column 3 passes through the center of the hemispherical block 2 .

[0031] Such as image 3 and Figure 5 As shown, a positioning mechanism 14 is installed on the top surface of the mounting base 1, and the positioning mechanism 14 includes a vertical rod 141 fixedly installed on the top surface of the mounting base 1. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com