3D printing device and method for high-viscosity resin multiple concentric structure

A 3D printing, high-viscosity technology, applied in coating devices, 3D object support structures, manufacturing tools, etc., can solve problems such as easy clogging and single material, and achieve the effect of expanding the range of materials, high control precision, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] The high-viscosity resin in the present invention refers to have shear-thinning property, at shear rate 0.1s -1 Under certain conditions, the apparent viscosity range is between 4000-10000Pa·s, and resin materials that are difficult to print by direct writing extrusion, Figure 5 It is the curve of the viscosity of typical printing materials changing with the shear rate.

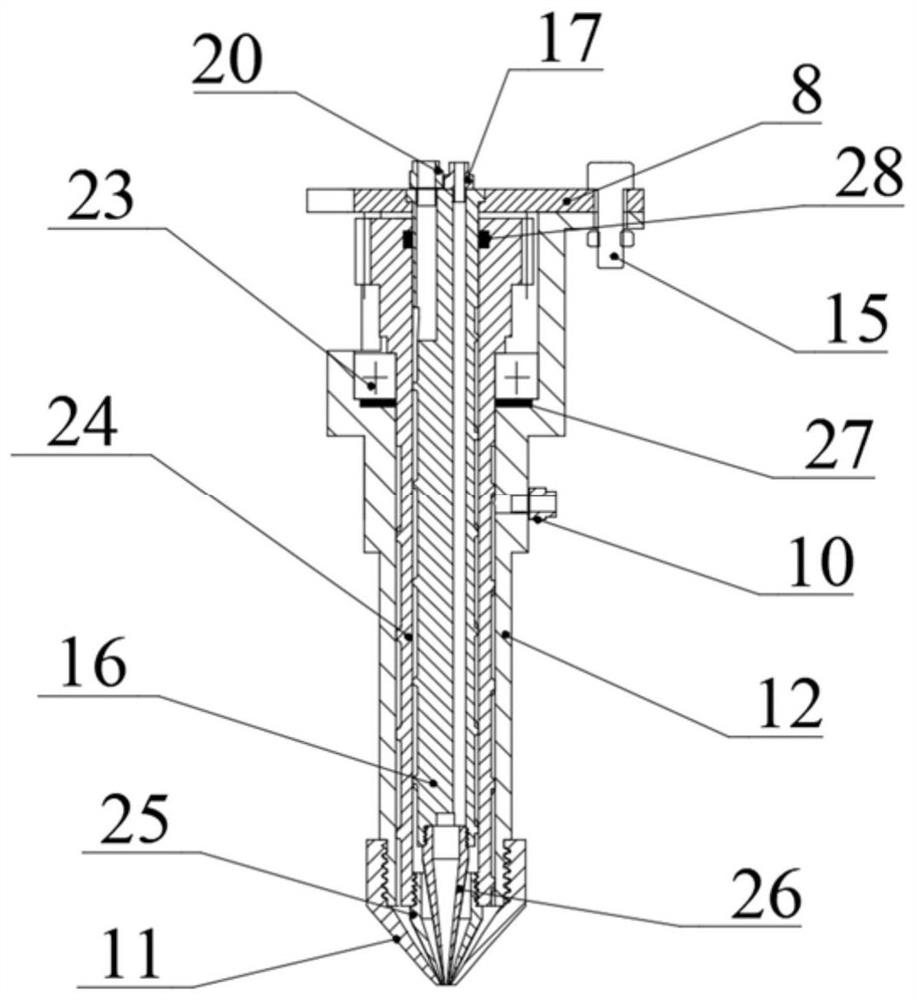

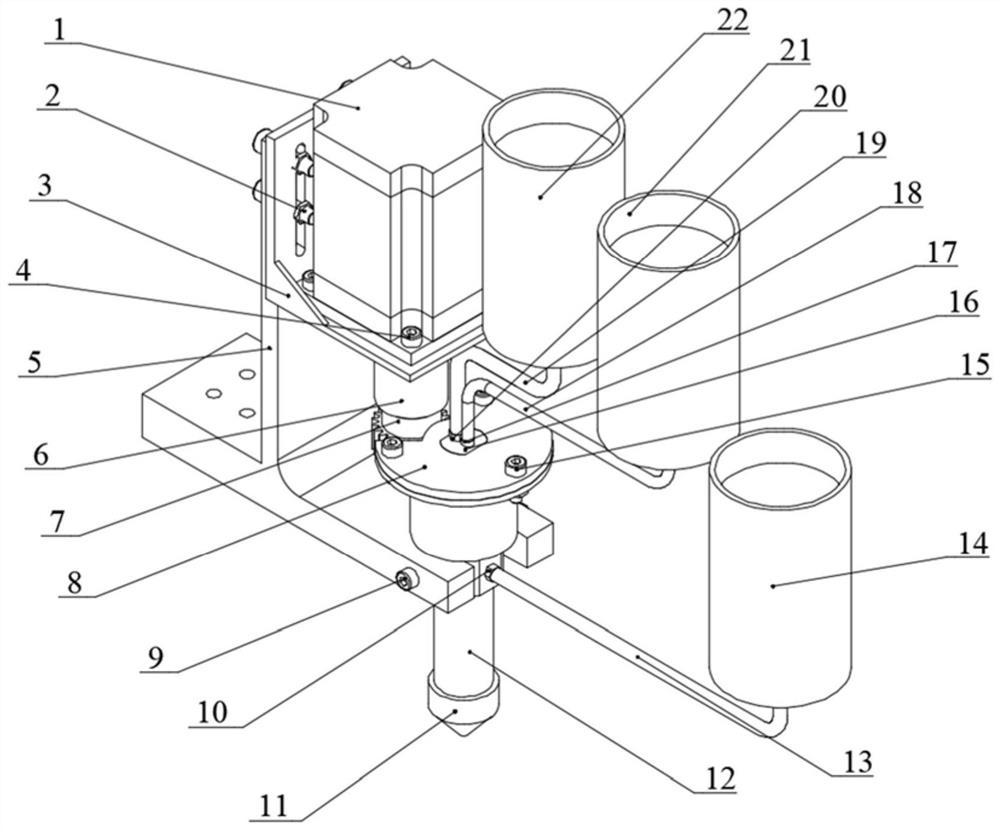

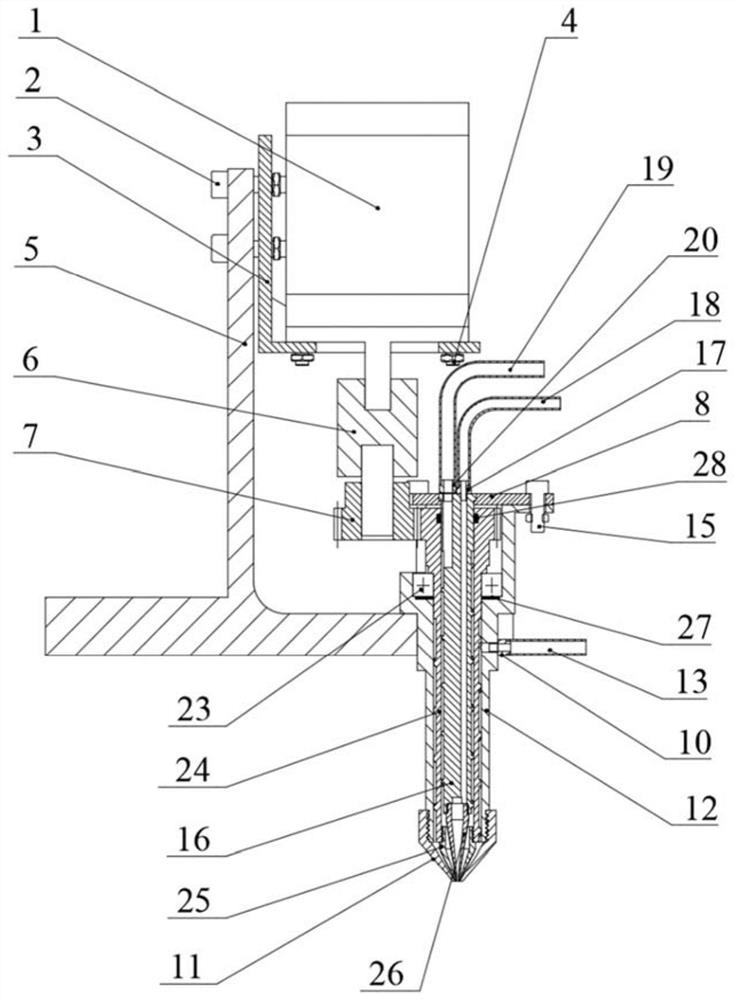

[0035] refer to figure 1 , figure 2 and image 3 , a 3D printing device for multiple concentric structures of high-viscosity resins, including a printing platform movable along XYZ three axes, on which a support plate 5 is arranged, and the support plate 5 includes a vertically arranged horizontal plate and a vertical plate, the vertical plate is arranged on the horizontal plate, and the shell cylinder 12 is arranged on the horizontal plate, and the shell cylinder 12 is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com