Individualized stoma base plate cutting method

A technology of stoma and chassis, applied in medical science, diagnosis, diagnosis recording/measurement, etc., can solve the problems of marking process error, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

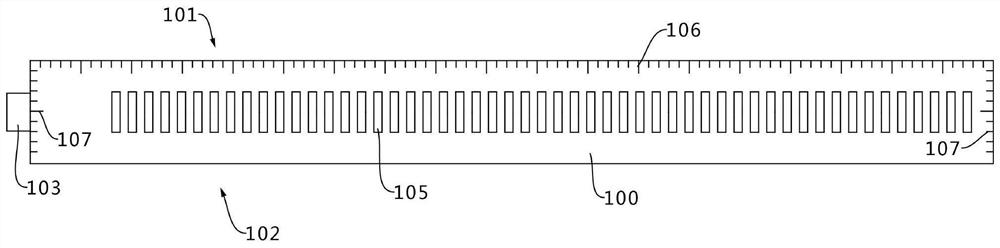

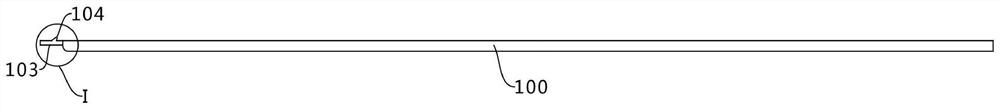

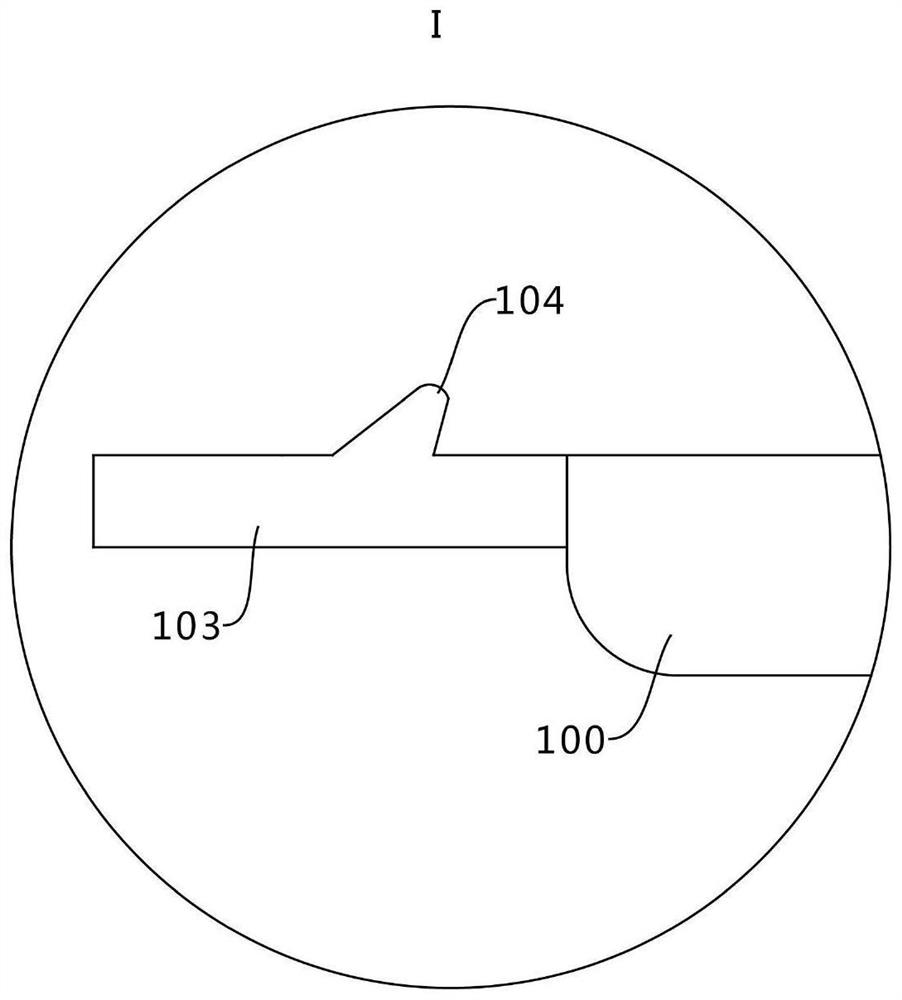

[0069] This embodiment provides a stoma measuring device, which includes a main body 100 in a belt-like structure, such as Figure 1-Figure 6 As shown, preferably, the thickness of the main body 100 can be 1-3mm, the length of the main body 100 can be 100-200mm, and the height of the main body 100 can be 10-30mm, so as to meet the needs of stomas 500 of different sizes. need.

[0070] In this embodiment, the main body 100 has plasticity, that is, the main body 100 can be bent under the action of external force, and when the external force is removed, the main body 100 can maintain a complete state. In order to realize this function, in a preferred implementation In this way, the main body 100 is made of rubber or silicone, so that the main body 100 is flexible and can be completely arbitrarily complete, so as to better fit (surround) the stoma 500; the main body 100 is embedded with a plastic part 108, the The plastic parts 108 can be iron wires, copper wires, iron sheets or ...

Embodiment 2

[0083] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in the stoma 500 measurer provided by this embodiment, the lower end 102 of the main body 100 is also provided with an extrusion part for adapting the chassis 600, so as to solve the problem of precisely cutting the chassis 600, specifically, in this embodiment, the extrusion part can be a concave-convex structure 201 constructed at the lower end of the main body, such as Figure 7 As shown, in order to increase the roughness of the lower end of the main body, in actual use, the user can press the lower end 102 of the main body 100 into the ink pad after the user completes the measurement of the stoma 500 and makes the stoma 500 measurer shaped. , so that the ink pad is immersed in the concave-convex structure 201, and then the user can print the lower end 102 of the main body 100 on the chassis 600 that needs to be cut, so as to print the outline of the stoma 500 on the chassis 60...

Embodiment 3

[0091] In order to solve the problem of convenient and precise cutting of the chassis 600, the main difference between this embodiment 3 and the above-mentioned embodiment 1 is that, in the stoma 500 measuring device provided by this embodiment, the lower end 102 of the main body 100 is also provided with a device for adapting the chassis 600 In this embodiment, the extrusion part includes several blades 301 with a set width, and the blades 301 are respectively vertically arranged on the lower end 102 of the main body 100, as Figure 12 As shown, and there is a set distance between two adjacent blades 301, by constructing a number of mutually independent blades 301 at the lower end 102 of the main body 100, on the one hand, the arbitrary deformation of the main body 100 will not be affected, and the main body 100 can still be easily A good fit of the stoma 500 can achieve the purpose of measurement. On the other hand, in actual use, the user can measure the stoma 500 after comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com