Environment-friendly machine for crushing and recycling glass

An environmentally friendly and mechanical technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of not being able to fully pulverize waste glass, affect the environment, and the effect of the pulverizer is not good, so as to avoid Effects of dust leakage, ensuring personal safety, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

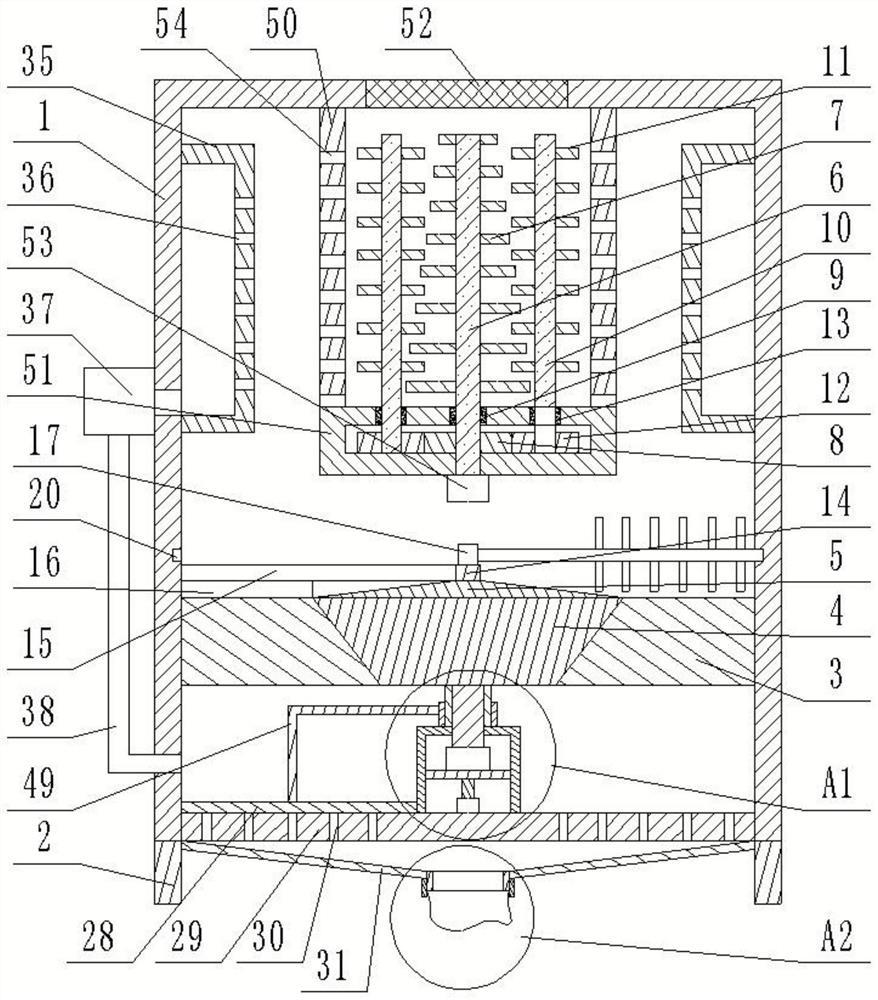

[0041] refer to Figure 1-5 , the present invention provides an environmentally friendly machine for glass crushing and reuse, including: a crushing shell 1, a crushing device, a grinding device, a dust adsorption device and a discharge device;

[0042] The bottom of the crushing shell 1 is fixedly connected with the support seat 2, the crushing device is arranged on the top of the inner cavity of the crushing shell 1, and is fixedly connected with the top surface of the inner cavity of the crushing shell 1, and the grinding device is set in the middle of the inner cavity of the crushing shell 1 , the dust adsorption device is arranged on the top of the inner wall of the crushing shell 1, and the discharge device is arranged on the bottom of the inner cavity of the crushing shell 1;

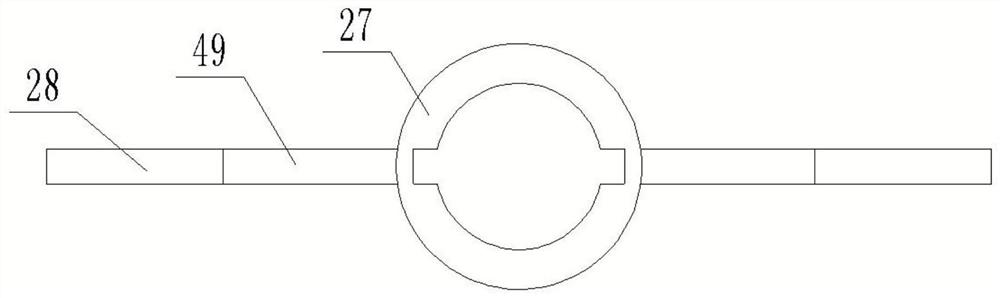

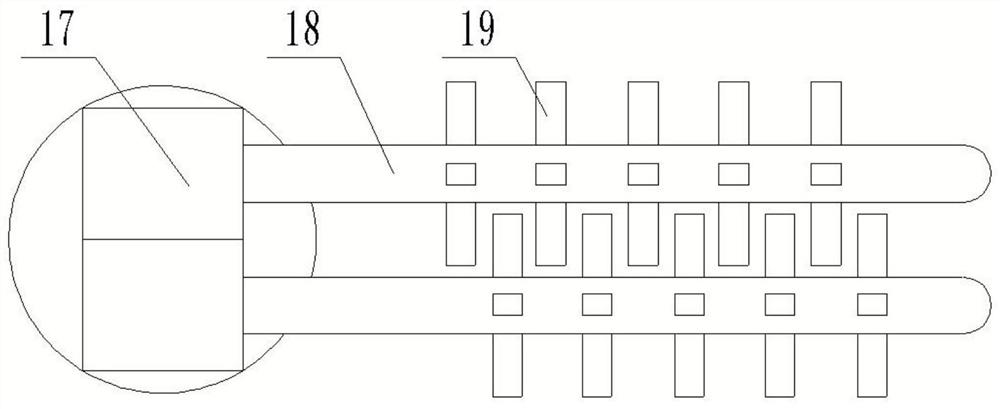

[0043] The grinding device includes a grinding ring 3, a grinding cone 4, a sweeping mechanism, a secondary crushing mechanism, a conical table 5 and a driving mechanism; the outer wall of the gr...

Embodiment 2

[0070] refer to Figure 6-7 , in order to improve the collection effect of the sweeping mechanism for glass slag, the present embodiment is also provided with a telescopic column 39, a telescopic spring 40 and a telescopic groove 41 in the sweeping mechanism;

[0071] The bottom of the connecting rod 15 is provided with some telescopic grooves 41, and the top surface of the sweeping rod 16 is fixedly connected with some telescopic columns 39 compatible with the telescopic grooves 41. The telescopic spring 40 is arranged in the telescopic groove 41, and one end of the telescopic spring 40 It is affixed to the inner wall of the telescopic groove 41, and the other end of the telescopic spring 40 is affixed to the top surface of the telescopic column 39;

[0072] Such setting in this embodiment can realize the effect of the sweeping rod 16 floating up and down in the process of collecting glass slag, avoiding the rigidity of the sweeping rod 16 when sweeping due to excessive accum...

Embodiment 3

[0074] refer to Figure 8-10 , in order to avoid the clogging of the crushing cylinder 50 due to the large volume of glass slag when the crushing device is performing preliminary crushing of glass, this embodiment is provided with an anti-blocking mechanism, including a material distribution rod 42, a cleaning ring 43. Cleaning rod 44, cleaning seat 45, guide rod 46, screw 47 and cleaning motor 48;

[0075]There are several distribution rods 42 in a circumferential array around the center of the top surface of the transmission cylinder 51. The cleaning seat 45 is sleeved on the outer wall of the transmission cylinder 51. The cleaning ring 43 is sleeved on the outside of several distribution rods 42. The cleaning ring 43 is set on the inner wall. A plurality of cleaning rods 44 are fixedly connected, and several cleaning rods 44 are intersected with the distribution rods 42. The cleaning motor 48 is arranged on the top surface of the cleaning seat 45, and one end of the screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com