Lanthanide fluoride two-dimensional nanosheet membrane and preparation method and application thereof

A lanthanide and two-dimensional nanotechnology, applied in the field of membrane separation, can solve problems such as changes, difficulty in industrial production, changes in selectivity and separation efficiency of graphene oxide membranes, and achieve high water flux and reusability The effect of high frequency and excellent water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a lanthanide fluoride two-dimensional nanosheet film, comprising the following steps:

[0033] In an inert gas atmosphere, water-soluble lanthanide metal salts and sodium acetate aqueous solution are mixed to obtain a mixed solution;

[0034] mixing the mixed solution with an aqueous fluorine-containing salt solution, and performing a precipitation reaction to obtain a suspension of two-dimensional nanosheets of lanthanide fluoride;

[0035] The lanthanide fluoride two-dimensional nanosheet suspension is deposited on a porous substrate, and dried to obtain the lanthanide fluoride two-dimensional nanosheet membrane, and the porous substrate is a polyethersulfone membrane, a nylon membrane, a poly Vinylidene fluoride membrane, polycarbonate membrane, ceramic membrane, metal membrane or anodized aluminum membrane.

[0036] The invention mixes water-soluble lanthanide metal salts and sodium acetate aqueous solution in an inert...

Embodiment 1

[0063] A method for preparing a high-performance lanthanide fluoride two-dimensional nanosheet film, comprising the following steps:

[0064] (1) In an inert gas atmosphere, dissolve 3.6mmol of cerium nitrate and 3.6mmol of sodium acetate solid powder in 300mL of deionized water successively, and stir until fully dissolved;

[0065] (2) Add 20 mL, 5 mg / mL ammonium fluoride aqueous solution to the mixed solution obtained in step (1), and react at room temperature for 2 h under stirring conditions to obtain a fluorine-cerium (F-Ce) nanosheet solution;

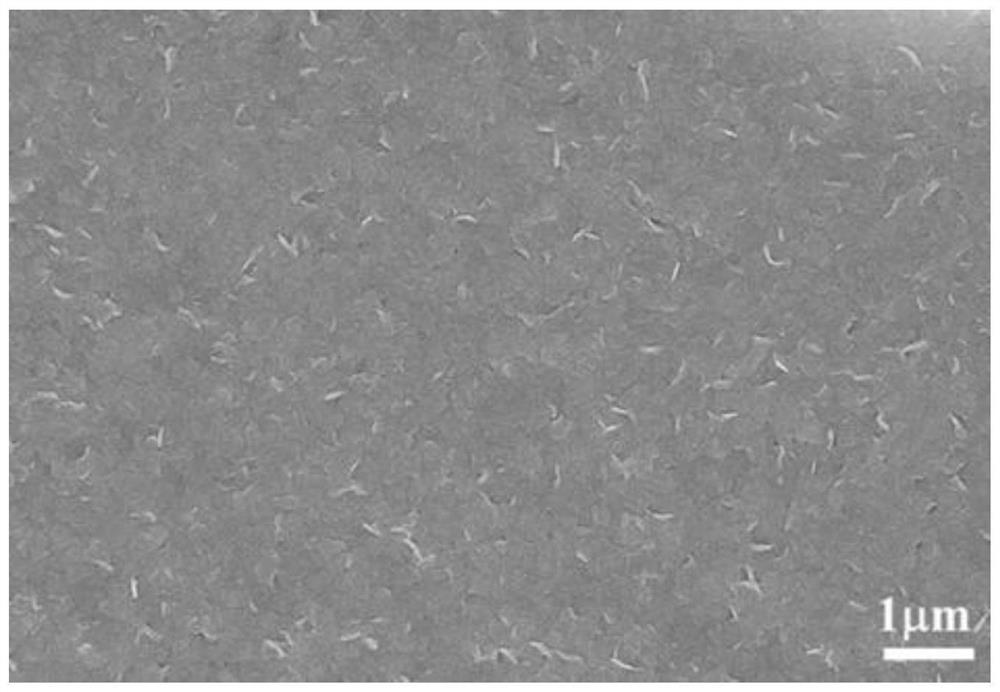

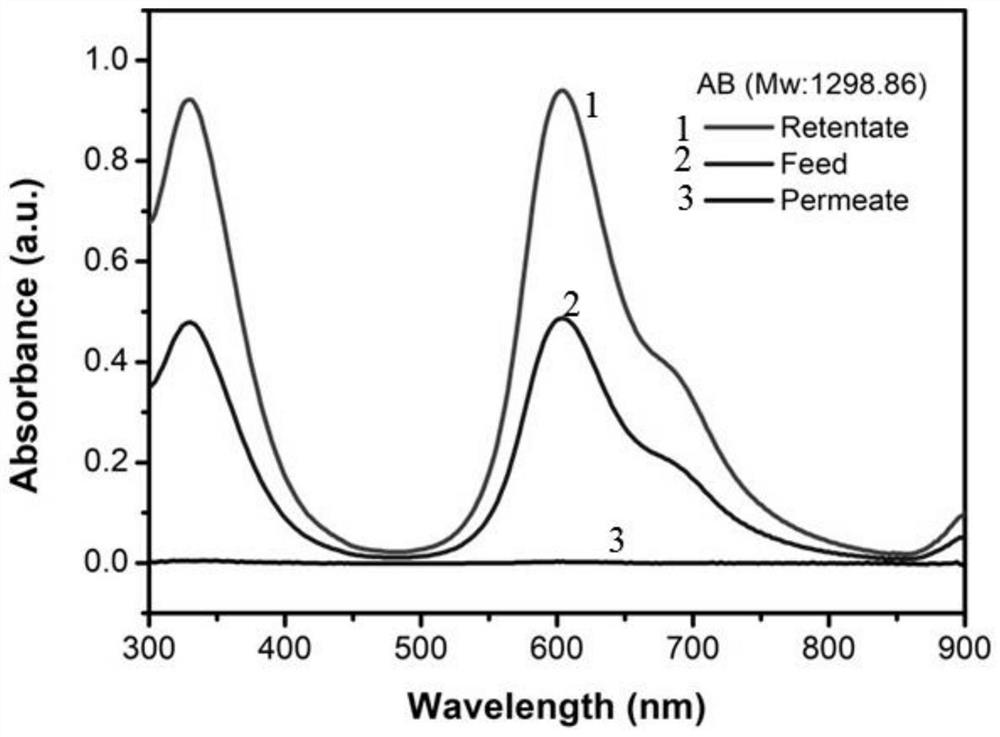

[0066] (3) Take 2mL of the F-Ce nanosheet solution prepared in step (2), and dilute it to 100mL with deionized water, and then through vacuum filtration, the F-Ce nanosheet is evenly loaded onto a polymer with a pore size of 60nm. On the ethersulfone porous substrate, the corresponding loading of F-Ce nanosheets is 0.57g / m 2 , after vacuum drying for 24h, a high-performance F-Ce two-dimensional nanosheet film was obtained.

[0...

Embodiment 2

[0071] A method for preparing a high-performance lanthanide fluoride two-dimensional nanosheet film, comprising the following steps:

[0072] (1) In an inert gas atmosphere, dissolve 1.2mmol of cerium acetate and 3.6mmol of sodium acetate solid powder in 200mL of deionized water successively, and stir until fully dissolved;

[0073] (2) Add 50mL, 30mg / mL sodium fluoride aqueous solution to the mixed solution obtained in step (1), react at room temperature for 5h under stirring conditions, and then centrifuge (3000rpm / min, 60min) to obtain F-Ce nanosheet suspension can be obtained;

[0074] (3) Take 4mL of the F-Ce nanosheet solution prepared in step (2), and dilute it to 100mL with deionized water, and then through vacuum filtration, the F-Ce nanosheets are evenly loaded onto a polymer with a pore size of 100nm. On the carbonate porous substrate, the corresponding loading of F-Ce nanosheets is 1.08g / m 2 , after vacuum drying for 24h, a high-performance F-Ce two-dimensional n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com