Method for rapidly salting salted egg yolk

A salted egg yolk, fast technology, applied in the protein composition of eggs, protein food composition, food science and other directions, can solve the problems of affecting product quality, the increase of sodium chloride content in egg white, and waste of egg white resources, etc., to achieve reasonable Utilization, accelerated penetration, less water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dry Pickling:

[0042] Spread 0.8cm high table salt in the transparent box, use a film with a diameter of 3.5cm and a height of 0.5cm to press out the salt nests, with a distance of 1.5cm between each salt nest. After separating the egg yolk and egg white under aseptic conditions, gently roll the egg yolk on the filter paper for 4-5 circles, remove the excess egg white on the surface, weigh (21.00±0.66g), and then put the egg yolk into the salt nest, Sprinkle a layer of table salt evenly on the surface of the egg yolk (0.05-0.1cm in height).

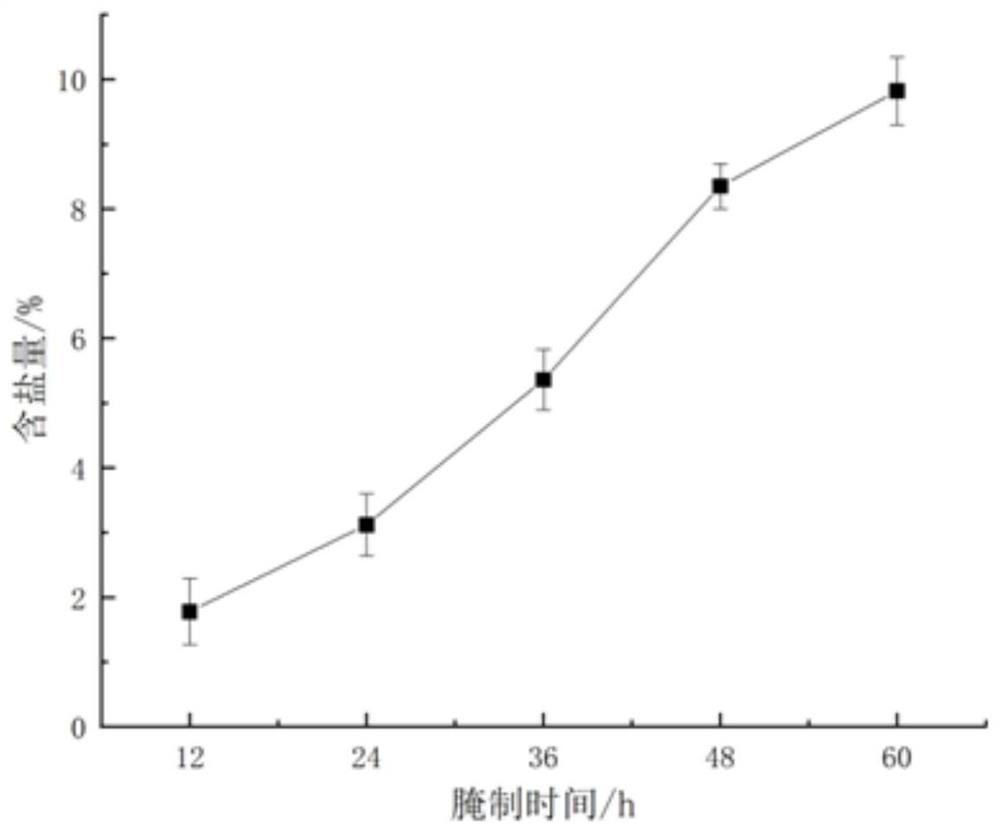

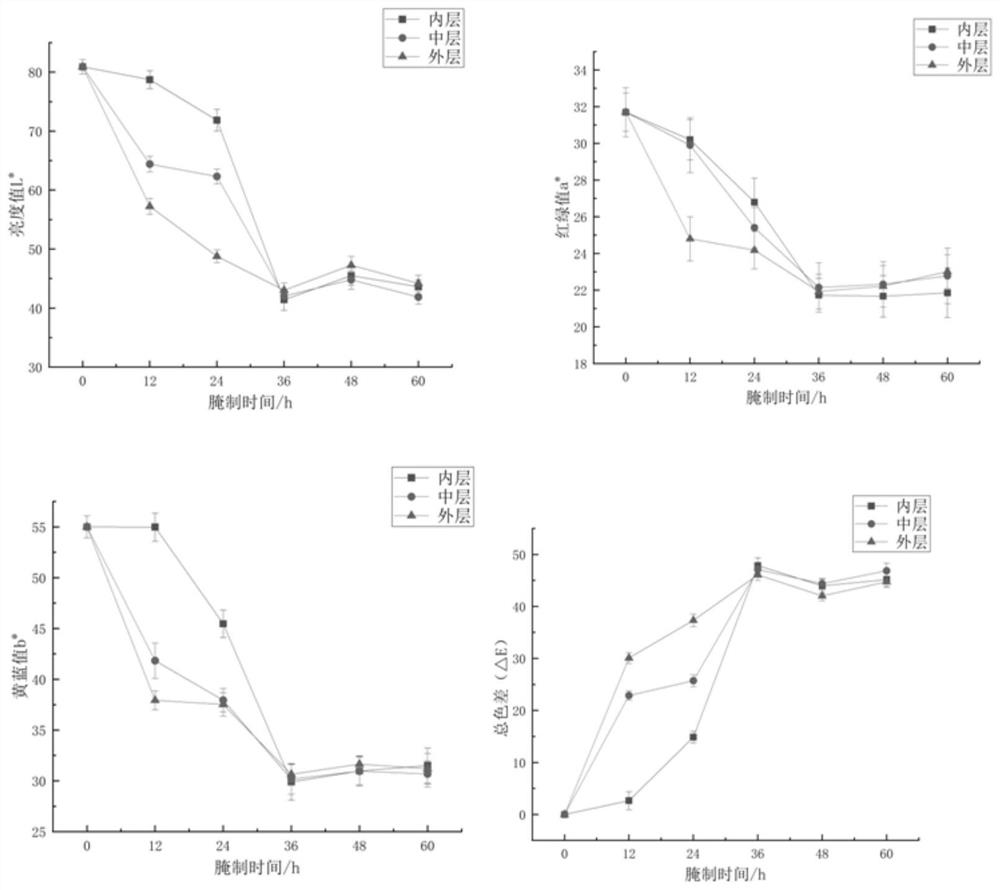

[0043] Changes of egg yolk salt content under different curing time conditions:

[0044] Weigh 3g of egg yolks from the pickling time of 0h, 12h, 24h, 36h, 48h and 60h into the conical flask, add AgNO 3 and concentrated HNO 3 solution, placed in a boiling water bath until the removal of AgCl 2 All other solids dissolve. Take it out and cool down, add 5% ferric ammonium sulfate solution and nitrobenzene after cooling, and the ...

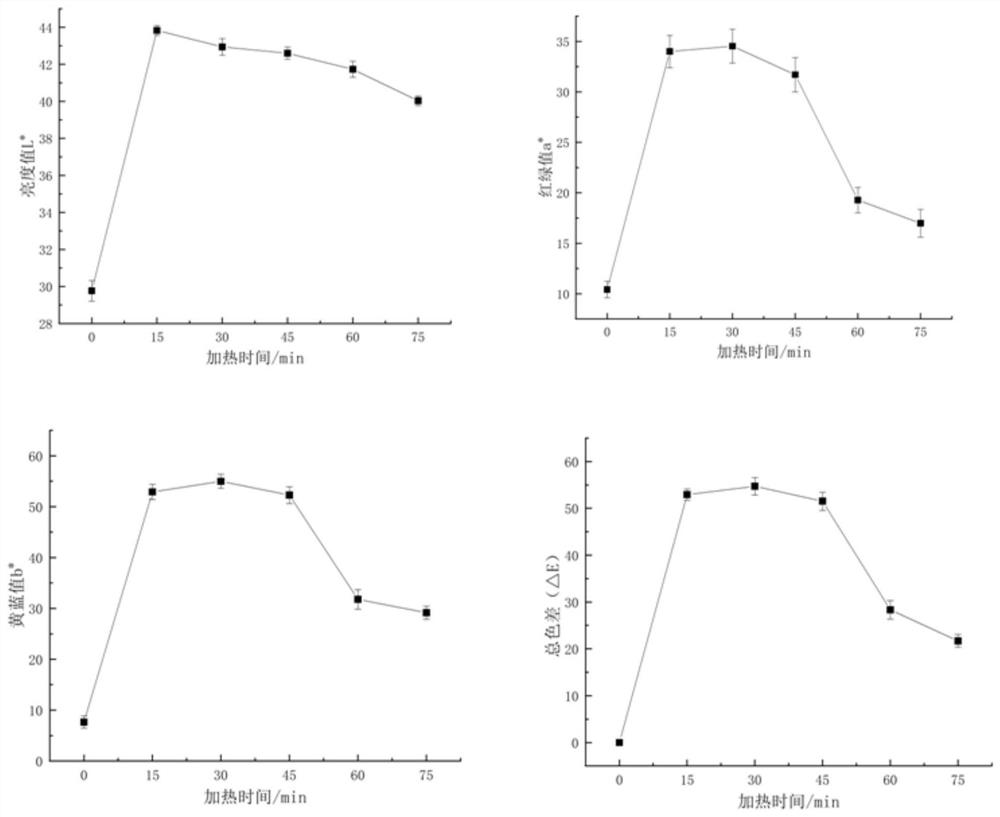

Embodiment 2

[0070] Spread 0.8cm high table salt in the transparent box, use a film with a diameter of 3.5cm and a height of 0.5cm to press out the salt nests, with a distance of 1cm between each salt nest. After separating the egg yolk and egg white under aseptic conditions, gently roll the egg yolk on the filter paper for 4-5 circles, remove the excess egg white on the surface, weigh (21.00±0.66g), and then put the egg yolk into the salt nest, Sprinkle a layer of table salt evenly on the surface of the egg yolk (0.05-0.1cm in height). Soak the egg yolks marinated for 36 hours in water for 15 minutes, wrap the egg yolks in baking paper, and heat them with dry air at a temperature of 100° C. for 45 minutes in a closed environment to obtain salted egg yolks. The measured oil yield was 18.65%±2.28%, and the total score of sensory evaluation was 94.0±4.3.

[0071] Vacuum packing:

[0072] Use vacuum packaging bags (specification: 15cm*8cm), put three egg yolks in each packaging bag, vacuumi...

Embodiment 3

[0074] Spread 1 cm high table salt in the transparent box, press out the salt nests with a film with a diameter of 3.5 cm and a height of 1.5 cm, with a distance of 1.5 cm between each salt nest. After separating the egg yolk and egg white under aseptic conditions, gently roll the egg yolk on the filter paper for 4-5 circles, remove the excess egg white on the surface, weigh (21.00±0.66g), and then put the egg yolk into the salt nest, Sprinkle a layer of table salt evenly on the surface of the egg yolk (0.05-0.1cm in height). Soak the egg yolks marinated for 36 hours in water for 15 minutes, wrap the egg yolks in baking paper, and heat them with dry air at a temperature of 110° C. for 40 minutes in a closed environment to obtain salted egg yolks. The measured oil yield was 17.78±1.28%, and the total score of sensory evaluation was 88.0±2.5.

[0075] Vacuum packing:

[0076] Use vacuum packaging bags (specification: 15cm*8cm), put three egg yolks in each packaging bag, vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com