Distribution pump arrangement for a hydraulic distribution system having changing flowing direction

A distribution pump, two-way hydraulic technology, used in fluid distribution devices, household appliances, heating systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] will combine figure 1 A first embodiment of a dispensing pump apparatus is discussed. According to this first embodiment, the distribution pump arrangement comprises a heat pipe control valve 20, a heat pipe distribution pump 22, pressure difference determining means 80, 80' and a controller 90. This first embodiment of the distribution pump apparatus is configured to reduce heat transfer from the hot conduit 12 to the cold conduit 14 when the partial pressure of the heat transfer fluid in the cold conduit 14 is higher than the partial pressure of the heat transfer fluid in the hot conduit 12 The partial pressure difference between fluids.

[0041] A heat pipe control valve 20 is arranged in the heat pipe 12 . Heat pipe control valve 20 may be controlled by controller 90 . The heat pipe control valve 20 can be set in an open state or a closed state. In the open state, the heat transfer fluid of the heat pipe 12 is allowed to flow through the heat pipe control ...

no. 2 example

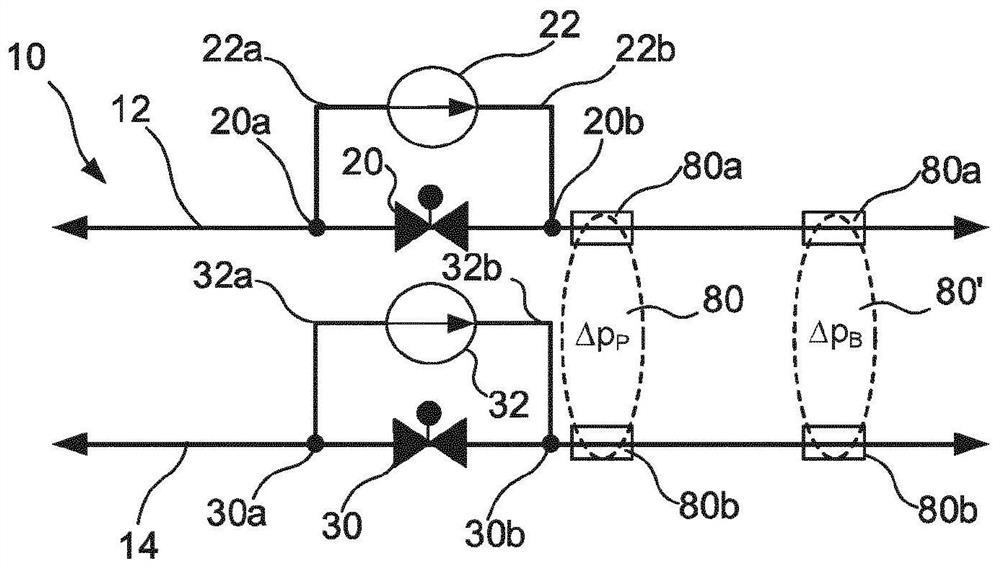

[0047] will combine figure 2 A second embodiment of a dispensing pump apparatus is discussed. In addition to the first embodiment of the dispense pump arrangement, this second embodiment further comprises a cold conduit control valve 30 and a cold conduit dispense pump 32 . As with the first embodiment of the dispense pump apparatus, this second embodiment is configured to reduce the pressure of the hot conduit 12 when the partial pressure of the heat transfer fluid in the cold conduit 14 is higher than the partial pressure of the heat transfer fluid in the hot conduit 12. The local pressure difference between the heat transfer fluid and the cold conduit 14.

[0048]A cold conduit control valve 30 is disposed in the cold conduit 14 . Cold conduit control valve 30 may be controlled by controller 90 . The cold conduit control valve 30 can be set in an open state or a closed state. In the open state, the heat transfer fluid of the cold conduit 14 is allowed to flow through t...

no. 3 example

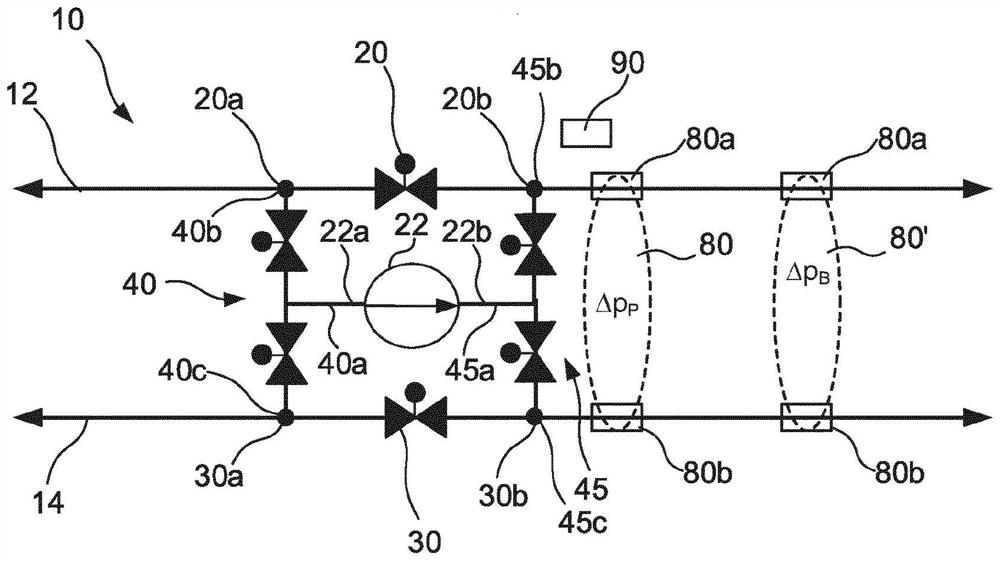

[0054] will combine image 3 A third embodiment of a dispensing pump apparatus is discussed. In addition to the first embodiment of the dispense pump apparatus, this third embodiment further includes a cold conduit control valve 30 , a first pump inlet valve assembly 40 , and a first pump outlet valve assembly 45 . As with the first embodiment of the dispense pump apparatus, this third embodiment is configured to reduce the pressure of the hot conduit 12 when the partial pressure of the heat transfer fluid in the cold conduit 14 is higher than the partial pressure of the heat transfer fluid in the hot conduit 12. The local pressure difference between the heat transfer fluid and the cold conduit 14. However, in addition to this, this third embodiment can also be configured to reduce the partial pressure of the heat transfer fluid in the heat pipe 12 when the partial pressure of the heat transfer fluid in the heat pipe 12 is higher than the partial pressure of the heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com