Flexible pressure sensor and preparation method thereof

A pressure sensor and flexible technology, applied in the field of pressure detection, can solve the problems of difficult assembly and low sensitivity, and achieve the effect of avoiding deformation of the membrane material, widening the detection range, and being light, thin and compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

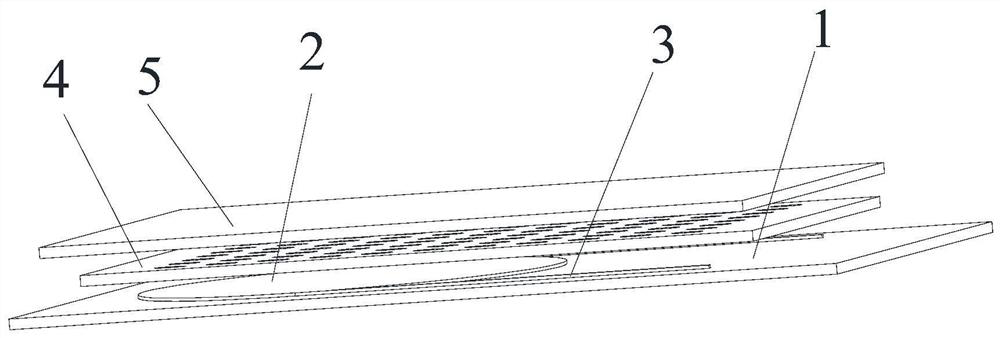

[0036] like figure 1 An embodiment of the present invention shown includes a flexible substrate 1, a patterned electrode 2 in close contact with the flexible substrate 1, a signal transmission electrode 3 electrically connected to the patterned electrode 2, and a pressure sensitive electrode covering and patterned on the electrode 2. The layer 4 , and the protective layer 5 covering the pressure-sensitive layer 4 ; the patterned electrode 2 and the signal transmission electrode 3 are in close contact with the upper surface of the flexible substrate 1 .

[0037] The concrete preparation method of embodiment 1 is:

[0038] S1. Select a flexible film or textile fabric as the flexible substrate 1 . The flexible substrate 1 can choose flexible films or textile fabrics with different thicknesses of 1 μm-1mm, different softness such as 2H, 4H, low modulus, and different light transmittance according to needs. You can choose one of fully transparent, translucent or opaque. From but ...

Embodiment 2

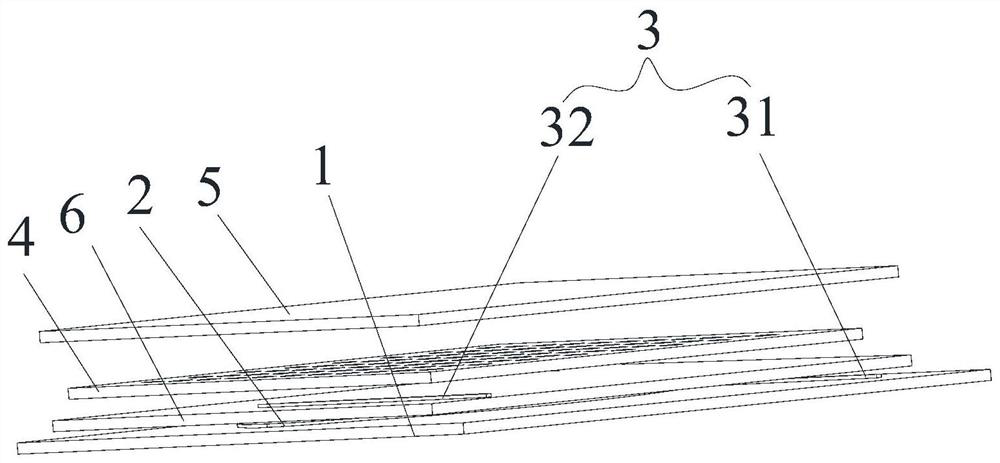

[0044] like figure 2 Another embodiment of the present invention shown includes a flexible substrate 1, a patterned electrode 2 in close contact with the flexible substrate 1, a signal transmission electrode A31 arranged on the flexible substrate 1 and electrically connected to the patterned electrode 2, covering the patterned electrode A31. The insulating layer 6 on the chemical electrode 2 and the signal transmission electrode A31, the signal transmission electrode B32 arranged on the insulation layer 6, the pressure-sensitive layer 4 covering the signal transmission electrode B32, and the protection covering the pressure-sensitive layer 4 layer 5, wherein the area of the pressure sensitive layer 4 completely covers the area of the patterned electrode 2. The position of the insulating layer 6 corresponding to the patterned electrode 2 has a window, and the signal transmission electrode B32 is electrically connected to the patterned electrode 2 through the window. The s...

Embodiment 3

[0053] like image 3 and Figure 4 Another embodiment of the present invention shown includes a flexible substrate 1, a patterned electrode 2, a signal transmission electrode 3, a pressure-sensitive layer 4 and a protective layer 5, wherein the patterned electrode 2 includes a flexible substrate in close contact with the upper surface of the flexible substrate 1. and the first patterned electrode 21 and the second patterned electrode 22 on the lower surface, the first patterned electrode 21 is covered with a first pressure sensitive layer 41, and the second patterned electrode 22 is covered with a second pressure sensitive layer 42, The first pressure-sensitive layer 41 is covered with a first protective layer 51, and the second pressure-sensitive layer 42 is covered with a second protective layer 52; the signal transmission electrode 3 includes a first signal transmission electrode 33 and a second signal transmission electrode 34, and the second pressure-sensitive layer 42 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com