Bolt axial force detection and automatic compensation device

An automatic compensation and axial force technology, applied in the direction of measuring devices, bolts, electric heating devices, etc., can solve the problems of safety accidents, looseness, etc., and achieve the effect of easy installation and disassembly, and safe and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

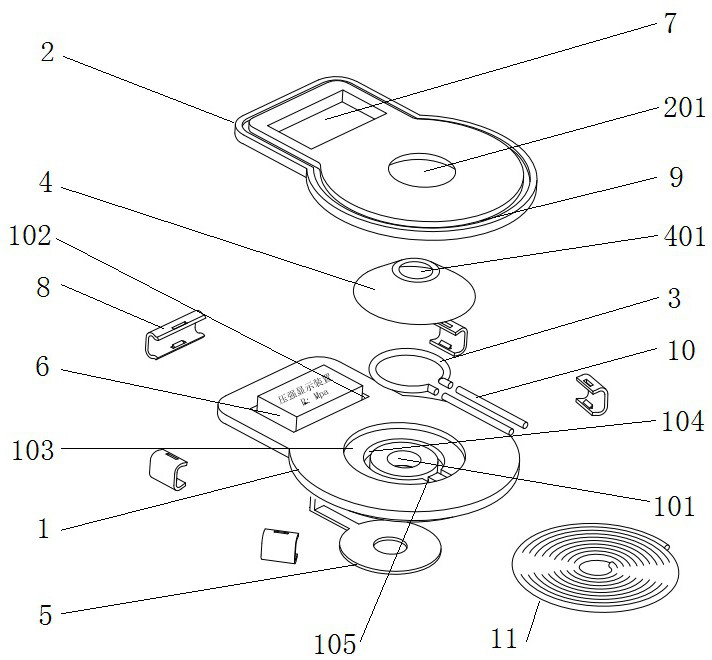

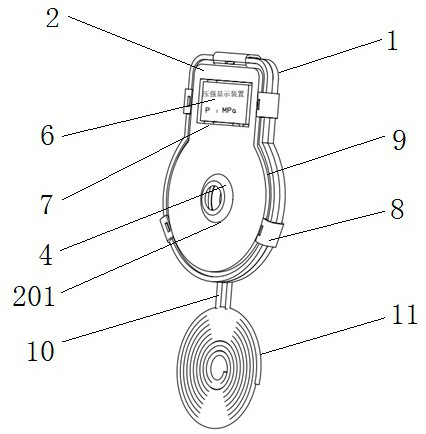

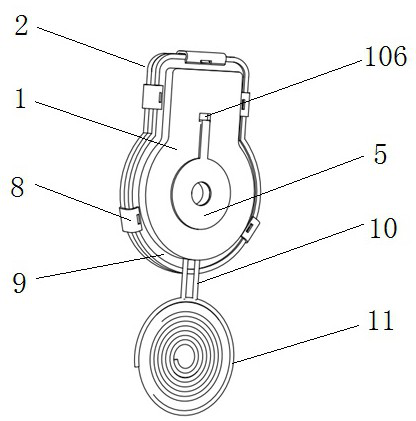

[0031] Example: such as Figure 1-7 As shown, a bolt axial force detection and automatic compensation device according to the present invention includes a heating pad carrier plate 1 and an end cover 2 that are mated and connected to each other, and through the heating pad carrier plate 1 and the end cover 2 The central hole is installed between the bolt and the connector; the middle part of the lower end of the heating pad carrier plate 1 is provided with a carrier plate center hole 101 through the bolt, and the heating resistance wire 3 and The shape memory alloy gasket 4 is located on the lower surface of the outer edge of the central hole 101 of the carrier plate and is connected to the thin film pressure sensor 5; the upper end of the heating gasket carrier plate 1 is provided with a square groove 102, and the thin film type The pressure display device 6 connected to the pressure sensor 5; the end cover 2 is connected to the upper surface of the heating pad carrier plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com