Roadway-free ground drilling fluidization coal mining method

A technology of ground drilling and coal mining, which is applied in the field of non-tunnel ground drilling fluidized coal mining and physical fluidized coal mining. It can solve the problems of complex coal and rock transportation equipment and high coal mining costs, and achieve low coal mining costs. , Improve mining efficiency and avoid sedimentation clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

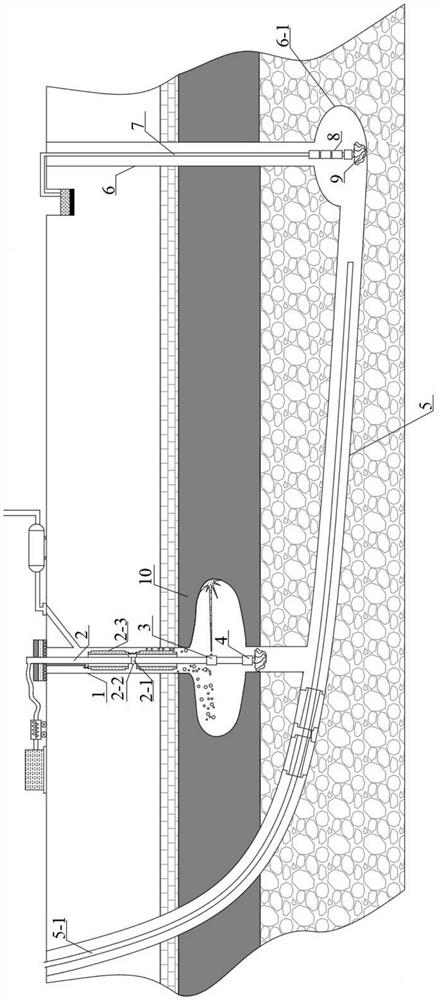

[0034] Such as figure 1 As shown, the non-tunnel surface drilling fluidized coal mining system includes a physical fluidized coal mining part and a coal-rock mixture conveying part.

[0035] The physical fluidized coal mining part includes a coal mining shaft 1, a high-pressure transport pipe 2 and a high-pressure jet 3; the coal mining shaft 1 driven vertically from the ground is set through the coal seam 10; the high-pressure transport pipe 2 penetrates It is installed in the coal mining shaft 1, and the top of the high-pressure transportation pipe 2 is clamped and installed on the transportation pipe rotation device, and installed at the wellhead of the coal mining shaft 1 through the transportation pipe rotation device. The high-pressure transportation pipe 2 Or the transport pipe rotating device is also provided with a transport pipe lifting control mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com