Shale gas reservoir multi-branch well detonation pressure reinforced extraction method

A shale gas reservoir, multi-branch technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of wellbore collapse, wellbore vulnerable, high explosive power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

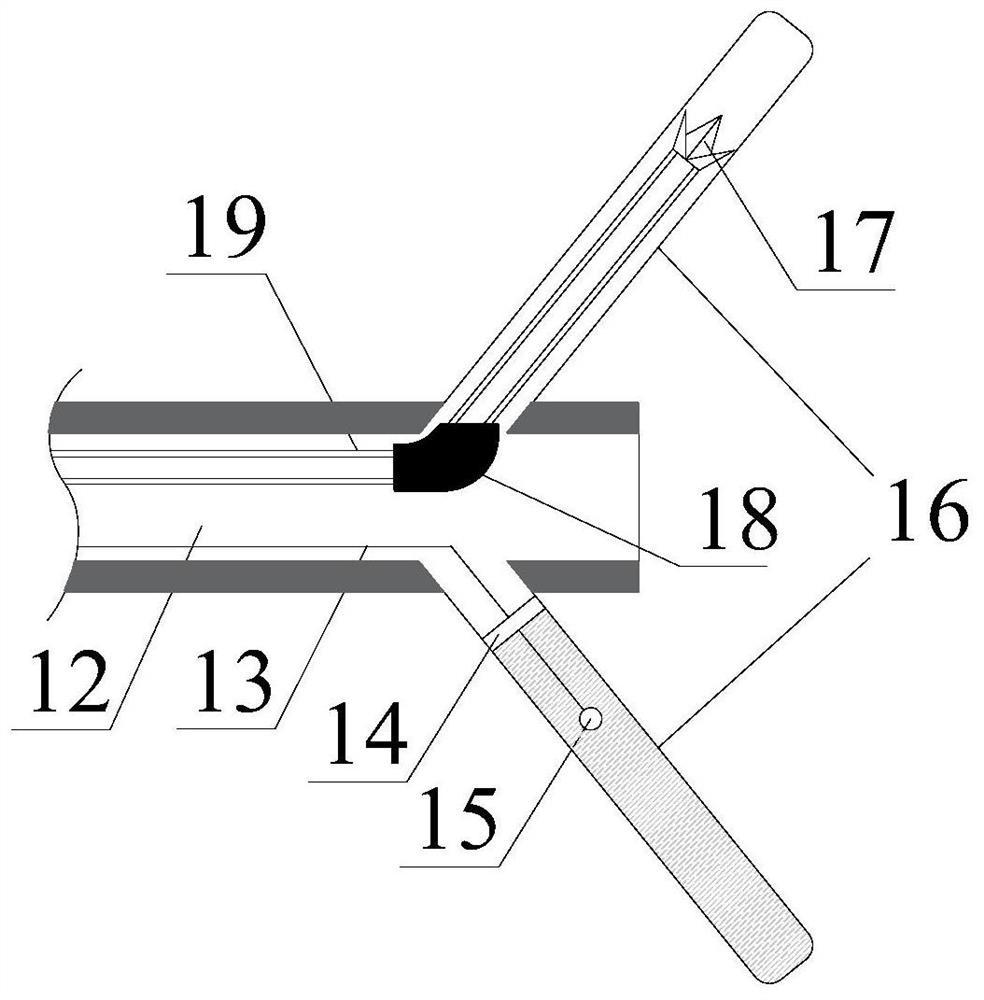

[0021] Example 1: Such as figure 1 , The specific steps of the present invention are:

[0022] A, shale reservoirs from ground to the desired extraction well established 9 hit 7, until the vertical shaft 9 reaches the target stop position shale reservoir 7, and 9 will be established during playing the well casing 10 is mounted to a vertical shaft 9 inner ring 11 and the cement injection layer of cement slurry is formed around the sleeve 10, is provided to complete the work of shaft 9;

[0023] B, in directional drilling extending into the vertical shaft 9 and reach the location shale reservoirs 7, 9 and hit the vertical shaft from the range of 7 shale reservoir wells 12 disposed horizontally, and the use of the sleeve 10 in supporting the horizontal well 12 ;

[0024] C, carrying flexible rod 19 of the injector 17 from the drill rig floor 5 extending into vertical shaft 9 and reach the level of 12 wells, the flexible rod 19 is provided with a hollow internal channel, the drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com