Shape self-adjusting type washing ball

A self-adjusting, laundry ball technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of reducing the moving ability of the laundry ball, poor speed of the laundry ball and clothes, and unsatisfactory enhancement effect, so as to achieve fast movement and reduce The effect of increasing the cleaning time and improving the cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

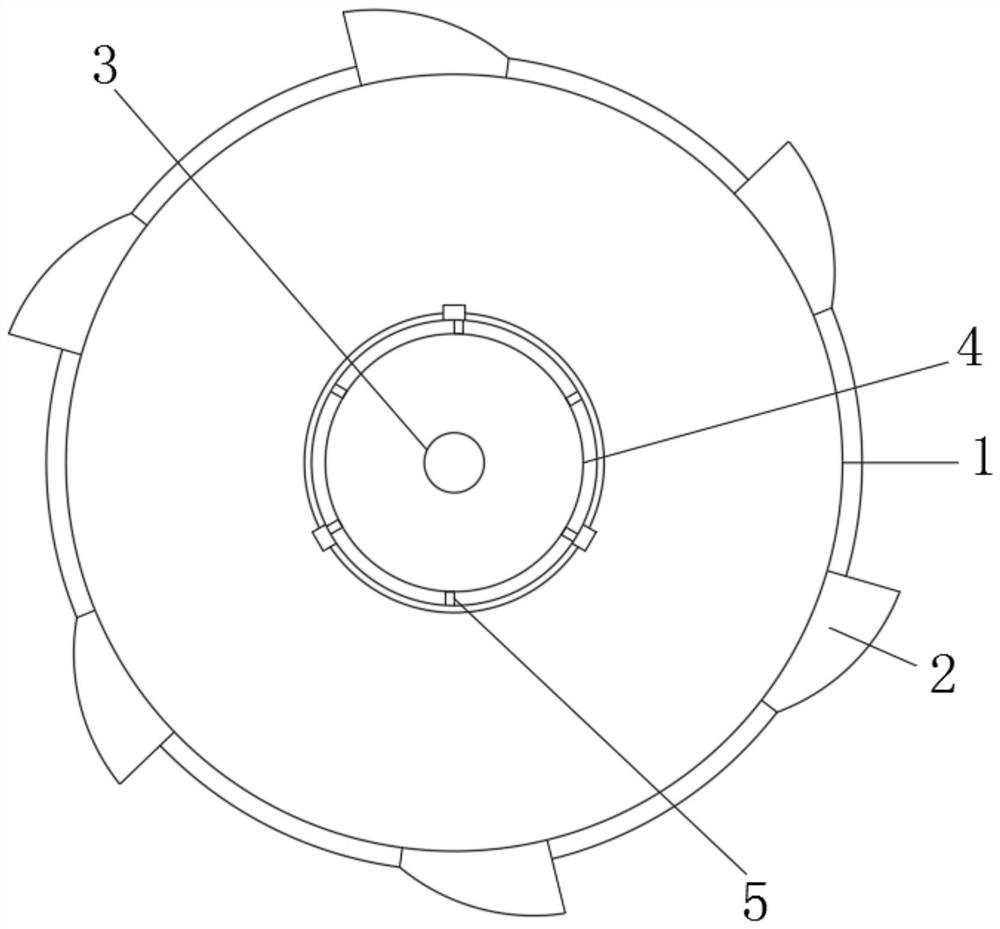

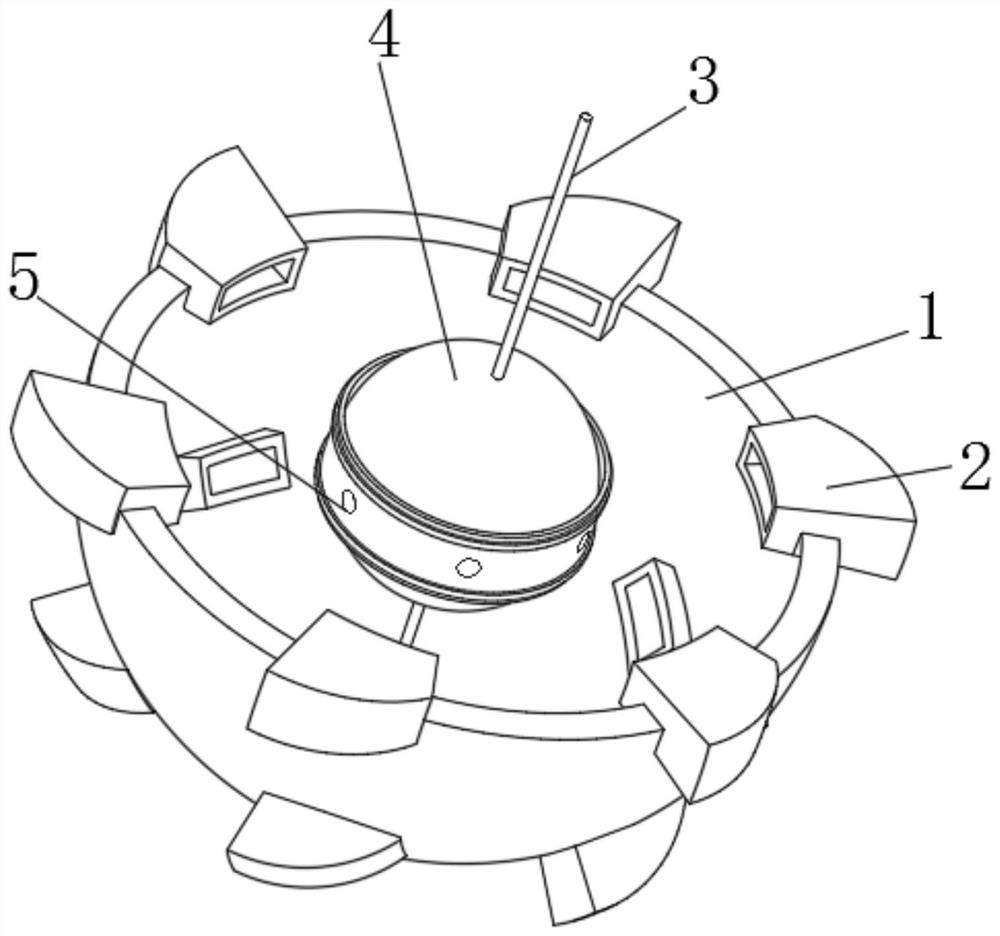

[0026] See Figure 1-2 A shape self-adjusted washing ball, including outer spheroid 1, and the outer spherical body 1 has elastic, compressible, and outer spherical body 1 having a cavity, and the outer spherical body 1 is connected to the inner sphere made of rigid material by the rotary shaft 3. 4, the inner sphere 4 is rotated about the rotating shaft 3, and cannot be compressed, the inner sphere 4 has a cavity, and the side wall of the outer spherium 1 is inlaid with an arc-shaped friction brush plate 2, a friction brush 2 hollow setting, friction brush plate 2 is made of an elastic material, a telescopic, and the cavity of the friction brush plate 2 is in communication with the outer spherical body 1, and the outer spheroid 1, the friction brush plate 2 and the inner spherical body 4 are filled with liquid when the friction brush plate 2 is not elongated. The inner sphere 4 is connected to the drive structure, and the cavity of the inner sphere 4 is in communication with the o...

Embodiment 2

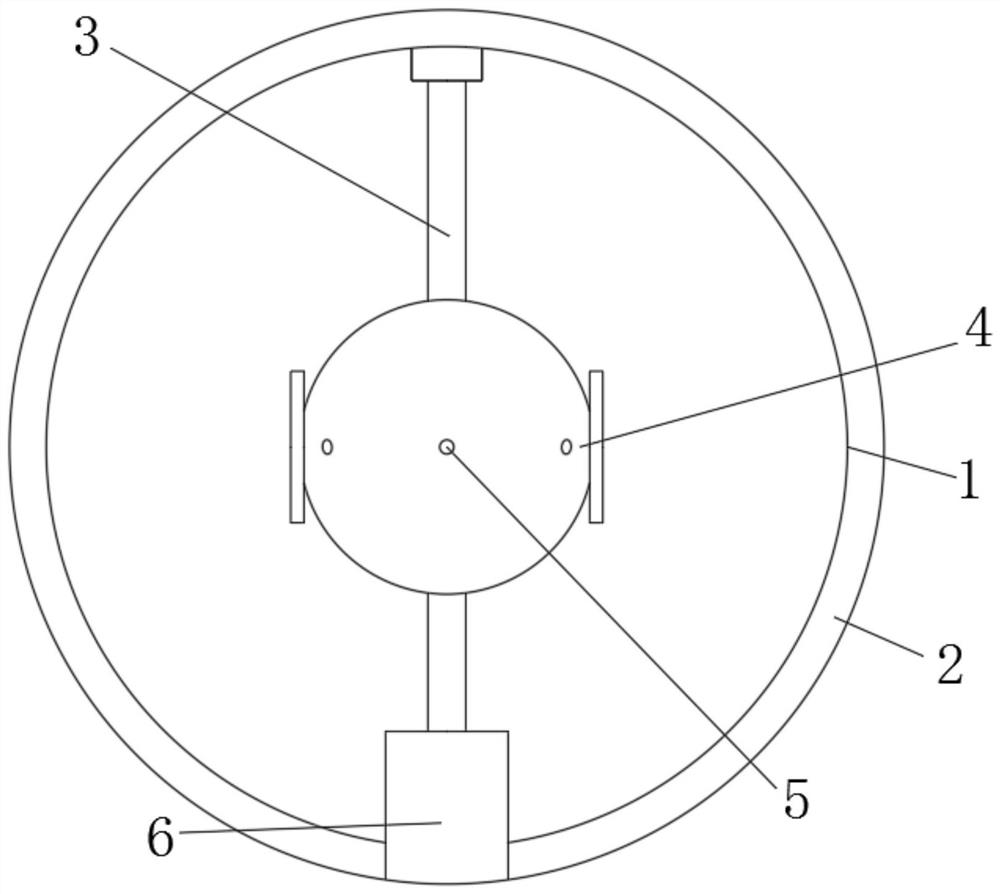

[0031] See Figure 5 Unlike the embodiment, the driving structure is composed of three eccentric pieces 7, and the three eccentric pieces 7 is surrounded around the equatorial line of the inner spherical body 4, and when the outer sphere 1 is moved with water, outer spheroid 1 Due to the stop of the friction, the internal eccentric pieces 7 are driven under inertia, and the outer spheroid 1 is compared, the structure is simple and the cost is low.

[0032] See Image 6 Among them, there is a connection plate 8 on the equator of the inner sphere 4, and a three sets of one-way bearings 9 are provided on the connecting plate 8, and the centrifugal block 7 is fitted on the unidirectional bearing 9, and the inner drive direction is the same as the inner sphere 4. The inner spherical 4 is rotated, and when the direction is inconsistent, the inner spherical 4 is rotated, and it is beneficial to the energy savings. Three groups are stunned, and three eccentric pieces 7 can be avoided.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com