Black shading conductive coating and preparation method thereof

A conductive coating, black technology, applied in conductive coatings, camouflage coatings, radiation-absorbing coatings, etc., can solve the problems of carbon-based conductive coating surface resistance, mechanical and physical properties, shading and shielding performance, etc., to achieve excellent shading and light absorption properties, excellent electrical conductivity, and the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

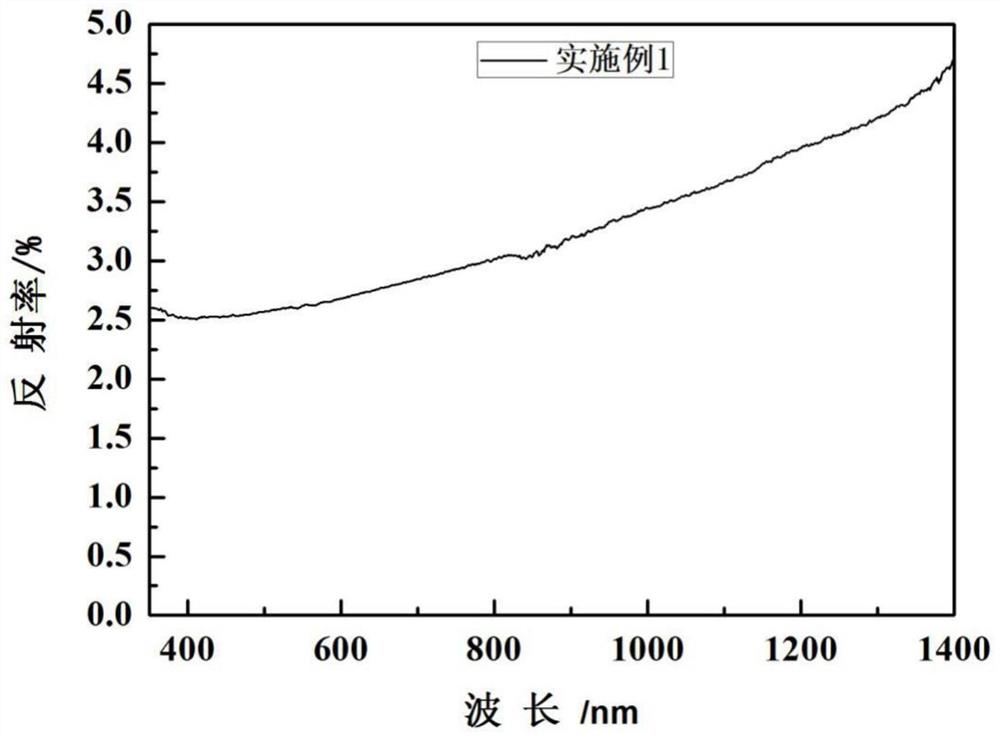

Embodiment 1

[0039] The present embodiment provides a kind of black light-shielding conductive coating, and this coating comprises A component and B component that mass ratio is 100:1; Described A component comprises two-component polyurethane, solvent, pigment filler and auxiliary agent; Described Component B is long-chain isocyanate, and the dosage is 1wt% of component A. In this example, component A is configured using the formula in Table 1:

[0040] Table 1

[0041]

[0042]

[0043] The preparation method of black light-shielding conductive paint in the present embodiment is as follows:

[0044] S1: Weigh film-forming substances, solvents, pigments and fillers and additives according to the mass ratio of each component in Table 1, and mix oily two-component polyurethane, DMF, conductive carbon black, graphite, nickel powder, dispersant, matting agent, ultraviolet Aging aids, light stabilizers and antioxidants were added to the reactor in proportion and mixed; then the mixed pow...

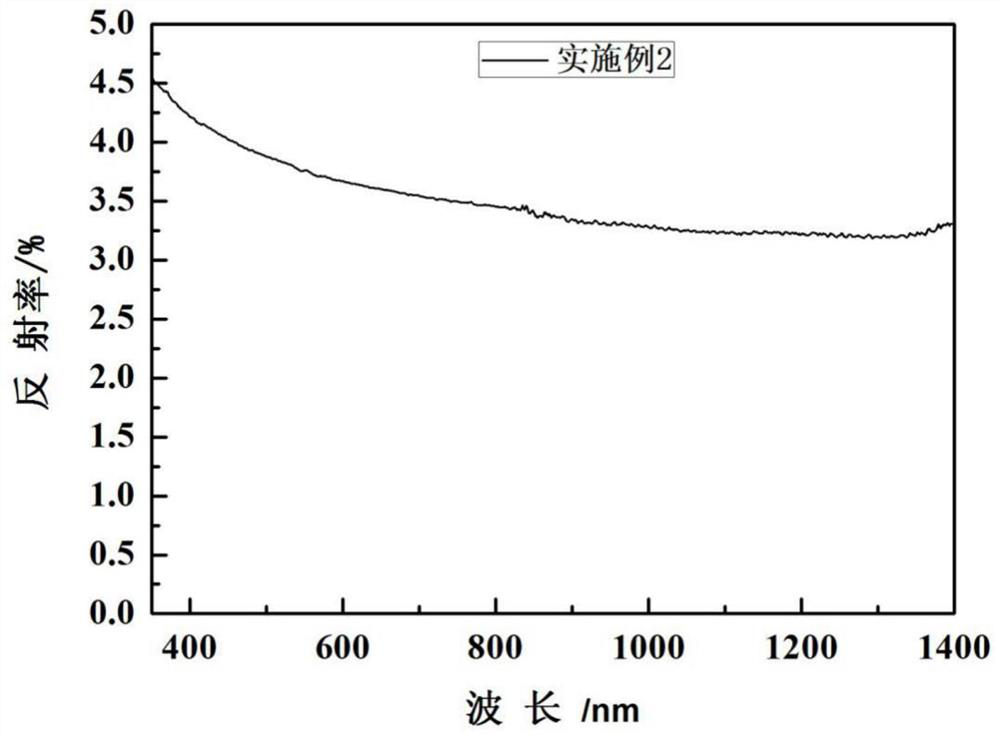

Embodiment 2

[0051] The present embodiment provides a kind of black light-shielding conductive coating, and this coating comprises A component and B component that mass ratio is 10:1; Described A component comprises two-component acrylic acid, solvent, pigment filler and auxiliary agent; Described Component B is long-chain isocyanate, and the dosage is 10wt% of component A. In this example, component A is configured using the formula in Table 3:

[0052] table 3

[0053]

[0054]

[0055] The preparation method of black light-shielding conductive paint in the present embodiment is as follows:

[0056] S1: Weigh film-forming substances, solvents, pigments and fillers and additives according to the mass ratio of each component in Table 3, and mix oily two-component acrylic acid, n-butyl acetate, conductive carbon black, graphite, nickel powder, dispersant, matting Agent, UV aging aid, light stabilizer and antioxidant are added in proportion to the reactor and mixed; then the mixed po...

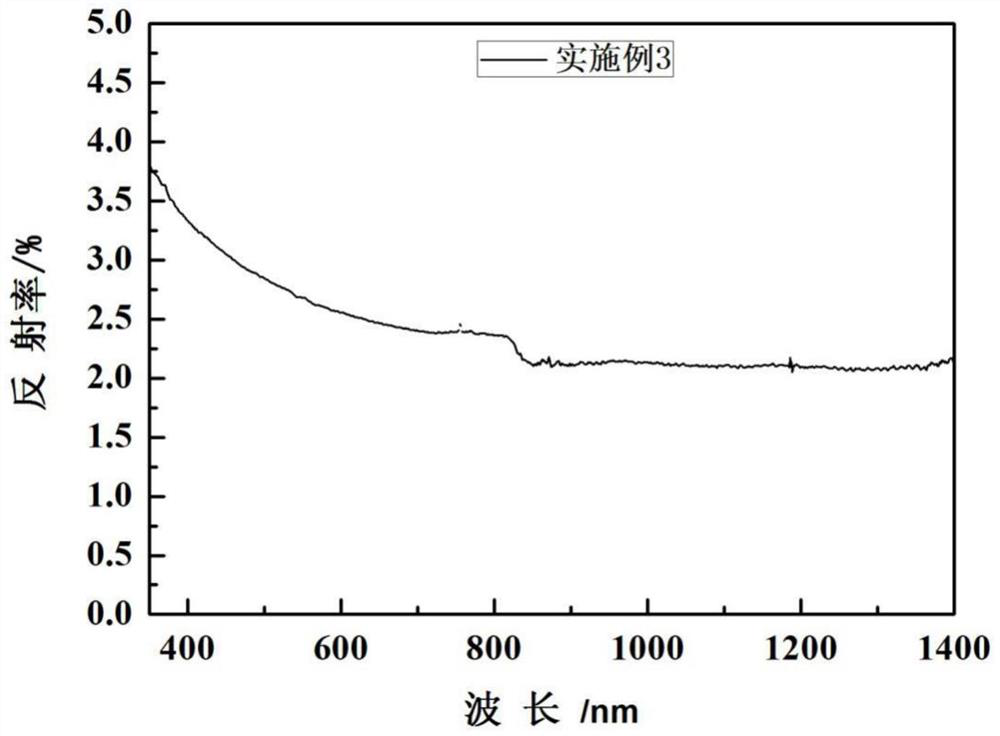

Embodiment 3

[0063] This embodiment provides a kind of black light-shielding conductive coating, and this coating comprises A component and B component that mass ratio is 100:20; Described A component comprises two-component epoxy resin, solvent, pigment filler and auxiliary agent; The B component is a long-chain isocyanate, and the dosage is 20wt% of the A component. In this example, component A is configured using the formula in Table 5:

[0064] table 5

[0065]

[0066] The preparation method of black light-shielding conductive paint in the present embodiment is as follows:

[0067] S1: Weigh film-forming substances, solvents, pigments and fillers, and additives according to the mass ratio of each component in Table 5, and mix oily two-component epoxy resin, ethanol, conductive carbon black, graphite, nickel powder, dispersant, and matting agent , ultraviolet aging aid, light stabilizer and antioxidant are added in proportion to the reactor and mixed; then the mixed powder and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com