Green low-creep concrete

A low-creep, concrete technology, applied in the field of building materials, can solve problems such as land secondary pollution, achieve the effects of reducing the amount of use, improving activity, and high comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the sludge powder from the waterworks comprises the following steps: (1) the sludge particles from the waterworks are uniformly heated for 0.6h, filled with steam during the heating process, and the microwave is turned on at full power for 25min at the same time, and the temperature in the kettle is stabilized at Between 185°C and 195°C, the pressure is controlled at 1.25MPa to 1.35MPa, and the temperature is kept constant for 5 hours; (2) Turn off all microwaves, turn off the power and cool down for about 1.5 hours, open the kettle door, dry and screen out sludge particles larger than 6mm in size (3) Calcining sludge particles with a particle size of less than 3mm at a temperature of 700-900°C for 1-2h, and calcining sludge particles with a particle size of 3-6mm at a temperature of 900-1000°C for 2-4h; (4) Natural cooling and mixing according to the mass ratio of 1:1 and grinding to obtain sludge powder from waterworks.

[0026] Furthermore, ...

Embodiment 1

[0032] Green low-creep concrete prepared by waterworks sludge powder and fine ceramic microbead aggregate, calculated by weight components, includes the following components,

[0033] 340 parts of cement with P O 52.5, 56 parts of sludge powder from waterworks, 45 parts of white corundum powder, 652 parts of river sand, 72 parts of fine ceramic microbead aggregate, 1087 parts of crushed stone, 136 parts of water, and 4.5 parts of water reducing agent parts, the water-to-binder ratio is 0.3.

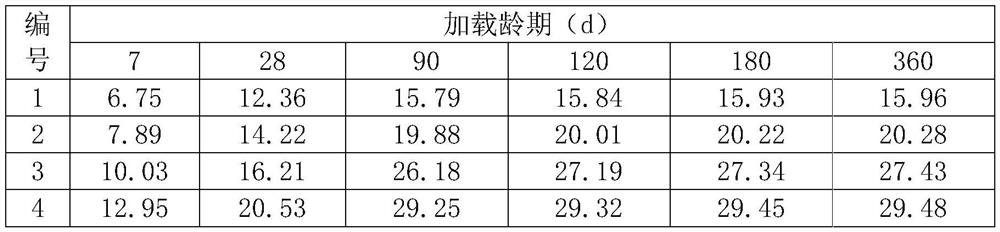

[0034] The technical indicators of the green low-creep concrete in this embodiment: the compressive strength of the 28d concrete is 59.8MPa, and the creep degrees of different ages are shown in Table 1.

Embodiment 2

[0036] Green low-creep concrete prepared by waterworks sludge powder and fine ceramic microbead aggregate, calculated by weight components, includes the following components,

[0037] 355 parts of cement with P O 52.5, 51 parts of sludge powder from waterworks, 46 parts of white corundum powder, 644 parts of river sand, 71 parts of fine ceramic microbead aggregate, 1072 parts of crushed stone, 152 parts of water, and 4.6 parts of water reducing agent parts, the water-to-binder ratio is 0.33.

[0038] The technical indicators of the green low-creep concrete in this embodiment: the compressive strength of the 28d concrete is 57.1MPa, and the creep degrees of different ages are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com