SBS latex modified asphalt mixture and warm-mixing direct-feeding preparation process thereof

A modified asphalt and mixture technology, applied in the field of modified asphalt, can solve problems such as insufficient crosslinking, gel, storage segregation, etc., and achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of AC-13 Modified Asphalt Mixture with SBS Latex

[0052] (1) Adjust the temperature of the mixing tank of the asphalt mixer to 135°C; heat 5000 grams of aggregate to 150°C and put it into the mixing tank. 2 grams of cross-linking agent was added to 17.5 grams of SBS latex, stirred in a blender for 10 minutes, set aside.

[0053] (2) Heat 245 grams of base asphalt to 140°C, add it into the mixing tank, and stir for 40 seconds.

[0054] (3) Add the SBS latex in step ① into the mixing tank, stir for 180 seconds, and discharge. Molding temperature: 130°C.

[0055] (4) Add mineral powder and stir for 180 seconds.

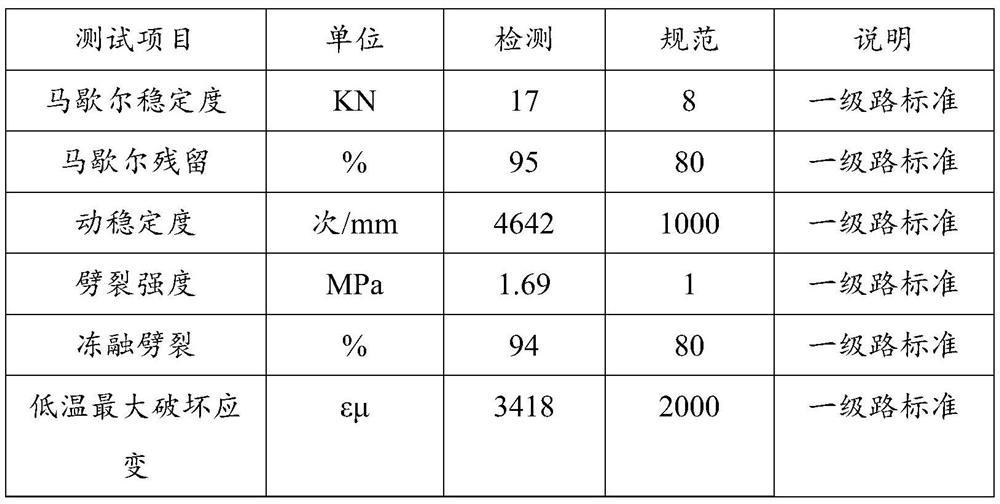

[0056] Manufacture Marshall test pieces, rut plates, and trabecular test pieces. The test results are as follows:

[0057]

Embodiment 2

[0059] Preparation of AC-16 Modified Asphalt Mixture with SBS Latex

[0060] (1) Adjust the temperature of the mixing tank of the asphalt mixer to 135°C; heat 5000 grams of aggregate to 150°C and put it into the mixing tank. 2 grams of cross-linking agent was added to 22.5 grams of SBS latex, stirred in a stirrer for 10 minutes, set aside.

[0061] (2) Heat 245 grams of machine-made asphalt to 135°C, add it into the mixing tank, and stir for 40 seconds.

[0062] (3) Add the SBS latex in step ① into the mixing tank and stir for 180 seconds.

[0063] (4) Add mineral powder, stir for 180 seconds, discharge, molding temperature: 130°C.

[0064] Manufacture Marshall test pieces, rut plates, and trabecular test pieces. The test results are as follows:

[0065] Test items unit detection specification illustrate Marshall stability KN 19 8 first class road standard Marshall residue % 99 80 first class road standard dynamic stability tim...

Embodiment 3

[0067] Preparation of SBS latex direct injection modified asphalt mixture SMA-13

[0068] (1) Adjust the temperature of the mixing tank of the asphalt mixture mixer to 150°C; heat 5000 grams of aggregate to 150°C and put it into the mixing tank. 2 grams of cross-linking agent was added to 26 grams of SBS latex, stirred in a blender for 10 minutes, set aside.

[0069] (2) Heat 330 grams of machine-made asphalt to 140°C, add it into the mixing tank, and stir for 40 seconds.

[0070] (3) Add the SBS latex in step ① into the mixing tank and stir for 180 seconds.

[0071] (4) Add mineral powder and stir for 180 seconds. Discharge, molding temperature: 135°C.

[0072] Manufacture Marshall test pieces, rut plates, and trabecular test pieces. The test results are as follows:

[0073]

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com