Automatic processing equipment and method for color steel film-coated plate

A technology for processing equipment and film-coated boards, applied in chemical instruments and methods, roller tables, lamination auxiliary operations, etc., can solve the problems of low degree of automation, poor practicability, and more surface dust, and reduce labor costs and manufacturing costs. Low, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

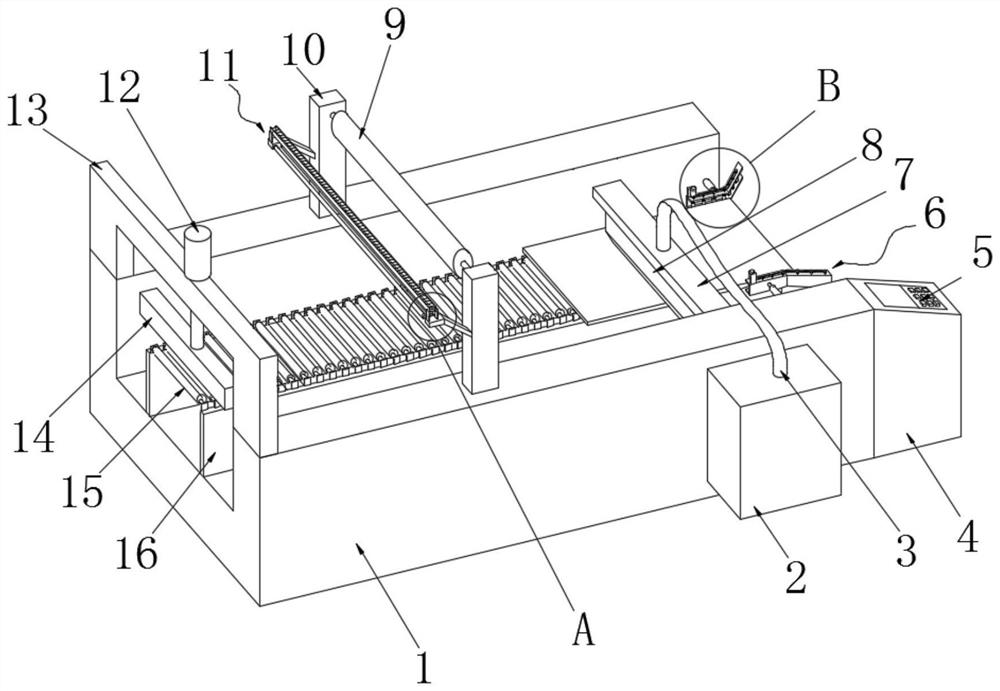

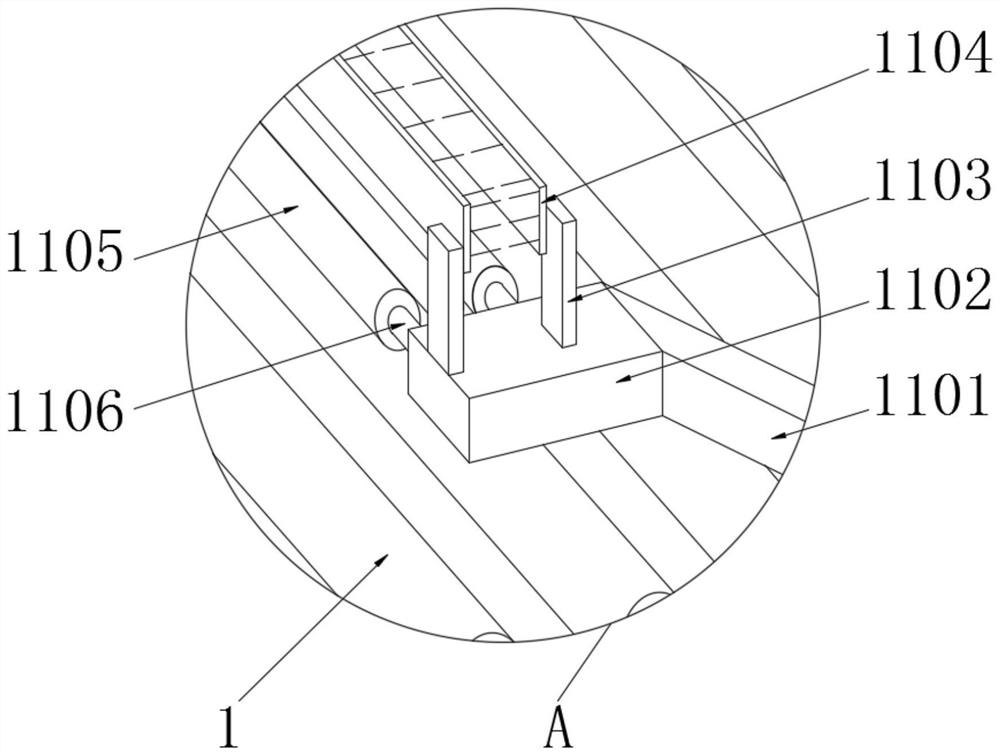

[0034] See Figure 1-5The present invention provides a technical solution: an automated processing apparatus for color steel coating plate, including a coating machine body 1, a dust box 2, a dust tube 3, an electric control box 4, a control panel 5, a positioning Guide mechanism 6, shunt plate 7, dust cover 8, first roller 9, support arm 10, dust removal mechanism 11, first hydraulic telescoping rod 12, gantry 13, membrane press head 14, conveying roller 15, mounting plate 16 , The exhaust fan 17 and the bag 18, the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com