A 00cr22ni5mo3n lock ring processing method that can eliminate deformation and reduce material consumption

A technology of processing technology and material consumption, which is applied in the production technology field of lock rings, can solve problems such as inappropriate forging forming methods, reduced material utilization rate, and unreasonable forging temperature, so as to reduce the influence of thermal stress, reduce residual stress, reduce The effect of product deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

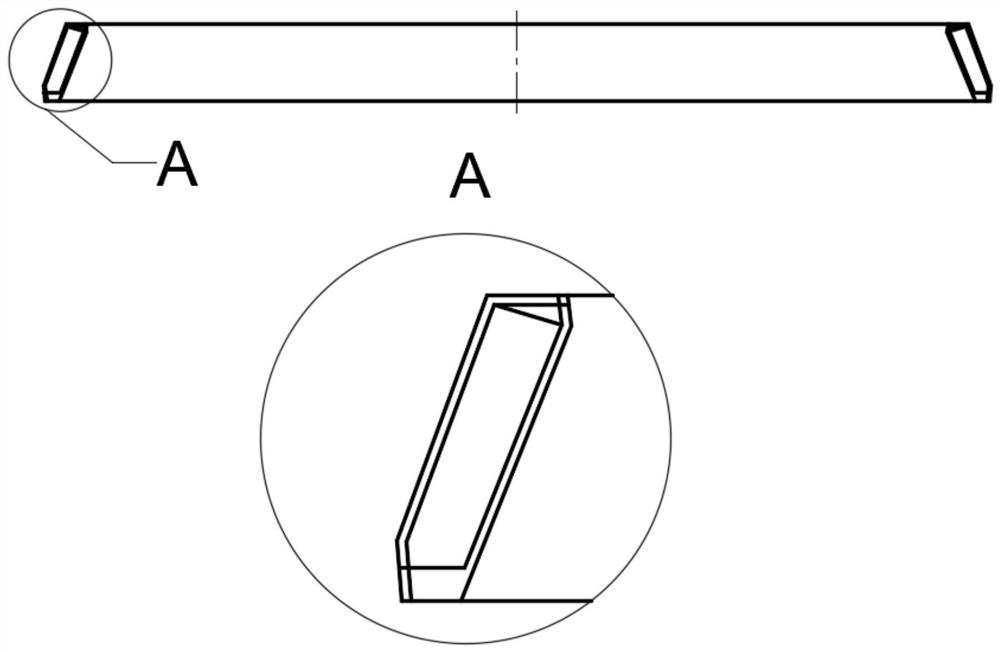

[0062] S1. The size of the blank is determined, two pieces are continuously forged and rolled, the raw material is a square forging blank, the clamping size is 20mm, and the incision size is 10mm;

[0063] S2. Heating the billet, heating the raw material of the forging billet, the heating rate is less than 100 ℃ / h before the temperature is lower than 850 ℃, and the heating rate is not limited after the temperature is higher than 850 ℃. , and finally heated to 1150°C for 4h;

[0064] S3. Forging a billet with a hammer. After heating, the billet is square. First, the corners are chamfered, then the billet is forged into a cylindrical shape, and finally a hole is punched in the center of the cylinder to obtain the initial billet;

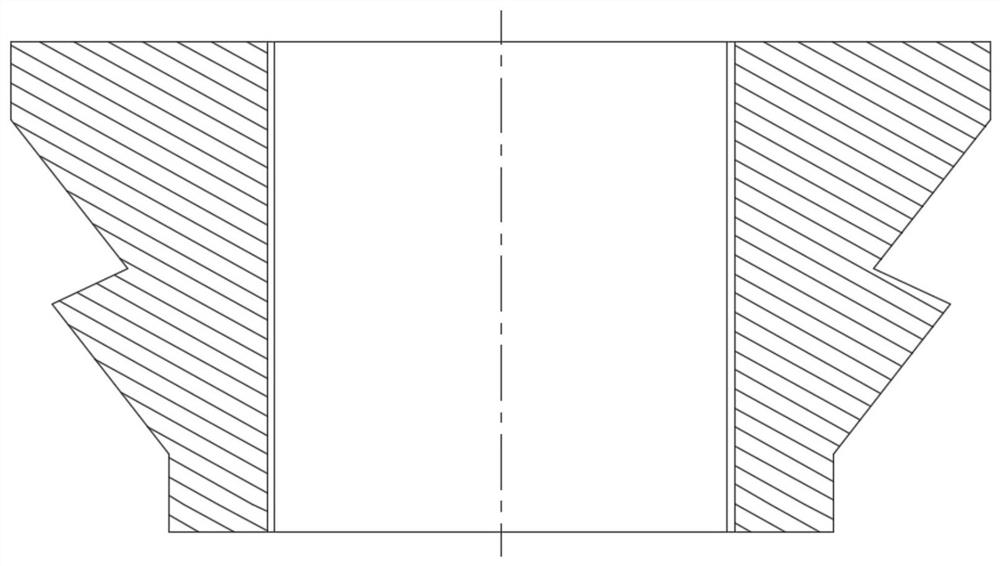

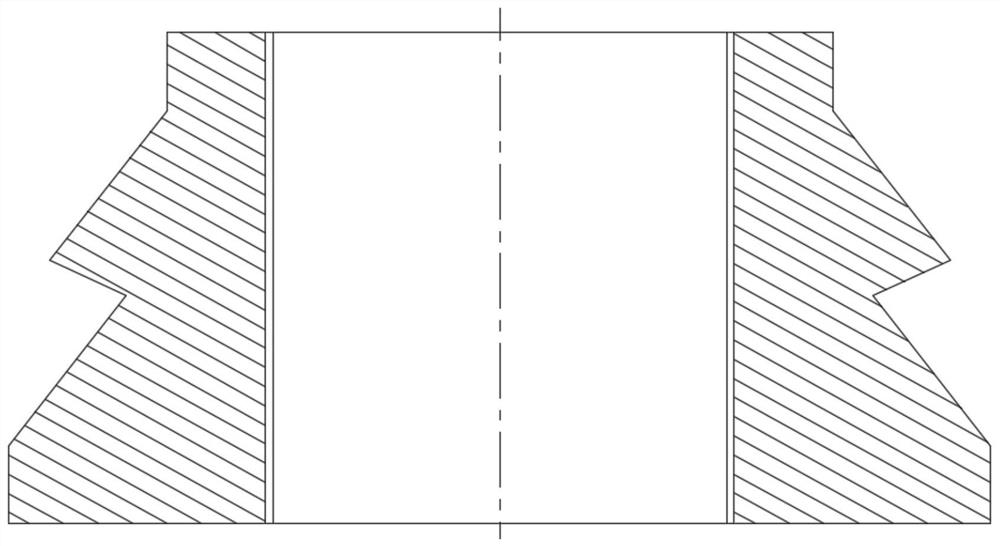

[0065] S4. Ring rolling machine is used for forming, using special spindle die and mandrel die, after three times of overheating and ring rolling, the heating speed is less than 100 °C / h before lower than 850 °C, and the heating speed is not limited af...

Embodiment 2

[0070] S1. The size of the blank is determined, two pieces are continuously forged and rolled, the raw material is a square forging blank, the clamping size is 20mm, and the incision size is 10mm;

[0071] S2. Heating the billet, heating the raw material of the forging billet, the heating rate is less than 100 ℃ / h before the temperature is lower than 850 ℃, and the heating rate is not limited after the temperature is higher than 850 ℃. , and finally heated to 1150°C for 4h;

[0072] S3. Forging a billet with a hammer. After heating, the billet is square. First, the corners are chamfered, then the billet is forged into a cylindrical shape, and finally a hole is punched in the center of the cylinder to obtain the initial billet;

[0073] S4. Ring rolling machine is used for forming, using special spindle die and mandrel die, after three times of overheating and ring rolling, the heating speed is less than 100 °C / h before lower than 850 °C, and the heating speed is not limited afte...

Embodiment 3

[0078] S1. The size of the blank is determined, two pieces are continuously forged and rolled, the raw material is a square forging blank, the clamping size is 20mm, and the incision size is 10mm;

[0079] S2. Heating the billet, heating the raw material of the forging billet, the heating rate is less than 100 ℃ / h before the temperature is lower than 850 ℃, and the heating rate is not limited after the temperature is higher than 850 ℃. , and finally heated to 1150°C for 4h;

[0080] S3. Forging a billet with a hammer. After heating, the billet is square. First, the corners are chamfered, then the billet is forged into a cylindrical shape, and finally a hole is punched in the center of the cylinder to obtain the initial billet;

[0081] S4. Ring rolling machine is used for forming, using special spindle die and mandrel die, after three times of overheating and ring rolling, the heating speed is less than 100 °C / h before lower than 850 °C, and the heating speed is not limited af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com