A bending device for thin-diameter thin-walled metal pipes

A technology of metal pipes and bending devices, which is applied in the direction of storage devices, feeding devices, positioning devices, etc., can solve the problems of low automation, unsuitable for batch production, and low processing precision, and achieve high automation, avoid bad deformation, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

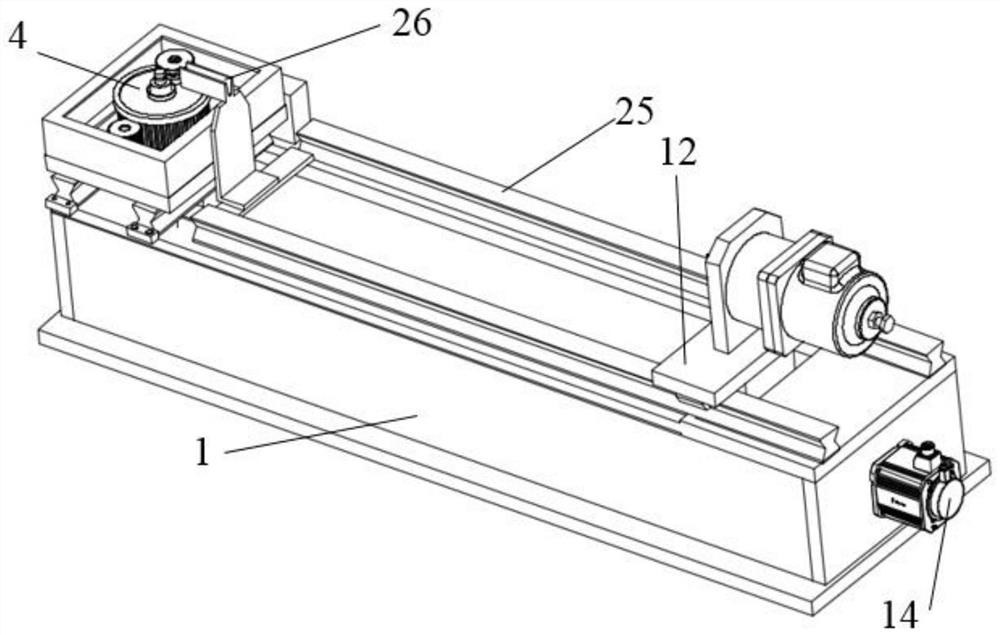

Embodiment 1

[0046] like Figure 1 to Figure 5As shown, the bending device for small-diameter and thin-walled metal pipes in this embodiment includes a frame 1, and one end of the frame 1 is provided with a clamping mechanism for clamping small-diameter and thin-walled metal pipes. The other end is provided with a bending mechanism for bending thin-diameter and thin-walled metal pipes. The bending mechanism includes a first motor 2 fixedly installed in the frame 1 and a first motor 2 sleeved on the first motor 2. Gear 3, the first gear 3 is meshed and connected to the second gear 4, the center of the second gear 4 is provided with a first positioning shaft 7, and the bottom of the first positioning shaft 7 is fixed on the bottom plate 10, so The bottom plate 10 is installed on the frame 1, the upper end surface of the first positioning shaft 7 is fixed with a fixed wheel 6, and the large gear 4 is also provided with a second positioning shaft 9, and the second positioning shaft 9 and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com