Device for bending air conditioner copper pipe of new energy automobile

A new energy vehicle and bending device technology, applied in the field of new energy vehicle processing, can solve the problems of manpower consumption and different bending angles, and achieve the effect of reducing manual operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

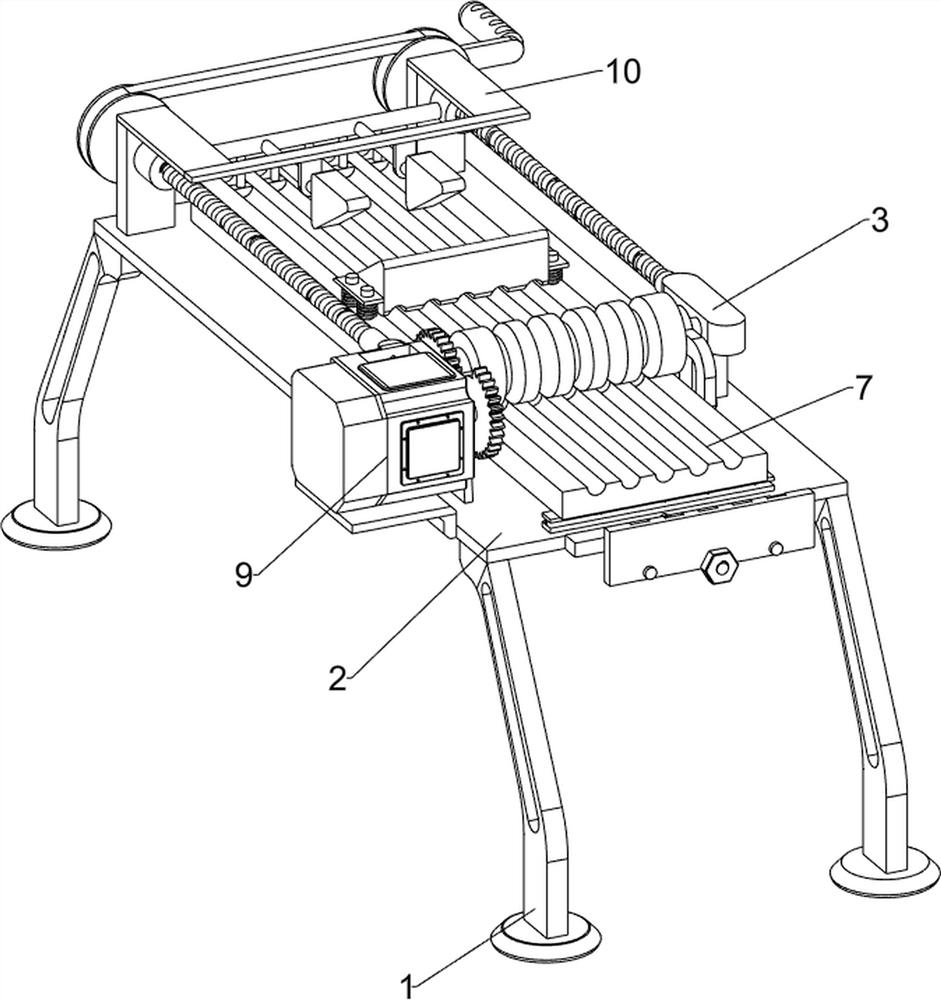

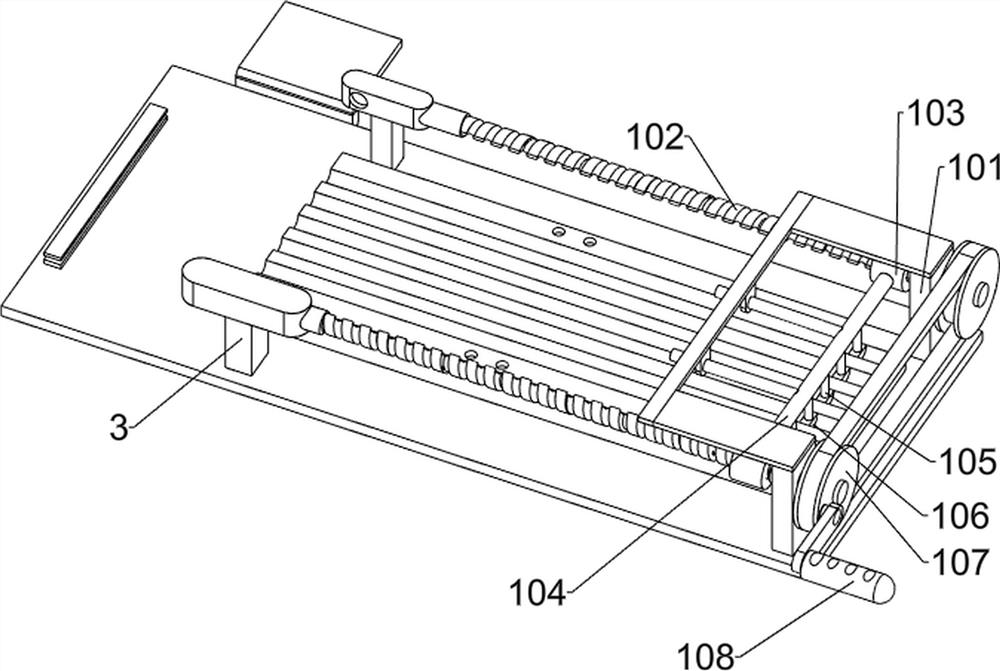

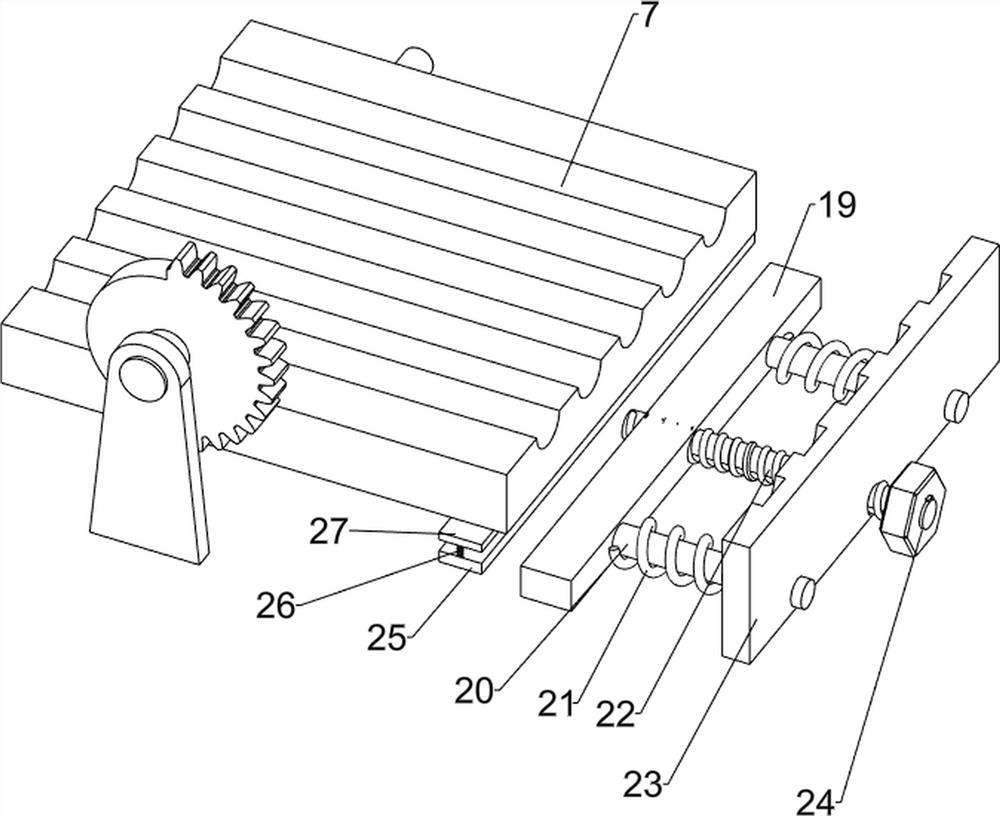

[0024] Such as figure 1 , figure 2 and image 3 As shown, a new energy vehicle air conditioner copper pipe bending device includes a foot 1, a workbench 2, a support seat 3, a transmission shaft 4, a connecting block 5, a connecting shaft 6, a movable plate 7, a placing plate 8, and a driving mechanism 9 And the push mechanism 10, the top of the support foot 1 is provided with a workbench 2, the front side of the top of the workbench 2 is symmetrically provided with a support seat 3, and a transmission shaft 4 is rotatably provided between the two support seats 3, and the left and right ends of the transmission shaft 4 are all provided There are connecting blocks 5, and connecting shafts 6 are arranged on the two connecting blocks 5, and a movable plate 7 is arranged between the two connecting shafts 6, and a semi-arc groove is evenly opened on the movable plate 7, and a Placement plate 8, semi-arc grooves are evenly opened on the placement plate 8, the movable plate 7 coop...

Embodiment 2

[0029] Such as Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, it also includes a guide column 11, a first elastic member 12, a guide plate 13 and a wedge-shaped pressing block 14, and two guides are symmetrically arranged in the middle of the workbench 2 with respect to the central axis of the placement plate 8. A first elastic member 12 is sheathed on the guide column 11 , a guide plate 13 is arranged on the guide column 11 on the same side, and a wedge-shaped pressing block 14 is arranged between the two guide plates 13 .

[0030] During the bending process, the staff can press the wedge-shaped pressing block 14, the first elastic member 12 is compressed, and the wedge-shaped pressing block 14 withstands the upper part of the copper pipe, which can prevent the movement during the bending process. After the bending is completed, the work The personnel releases the wedge-shaped pressing block 14, and the first elastic member 12 drives the wedge-shaped pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com