Raw material cleaning device in poria cocos extract process

A technology of Poria cocos extract and cleaning device, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, and can solve the problems of low cleaning and separation efficiency of Poria cocos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

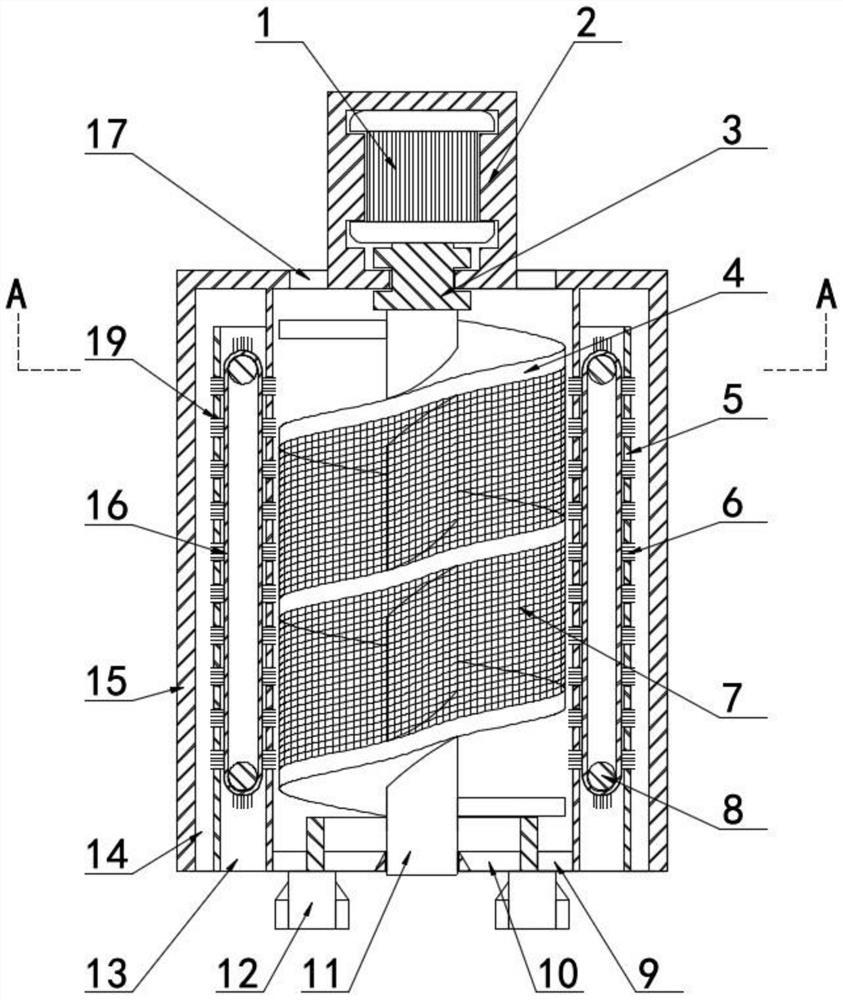

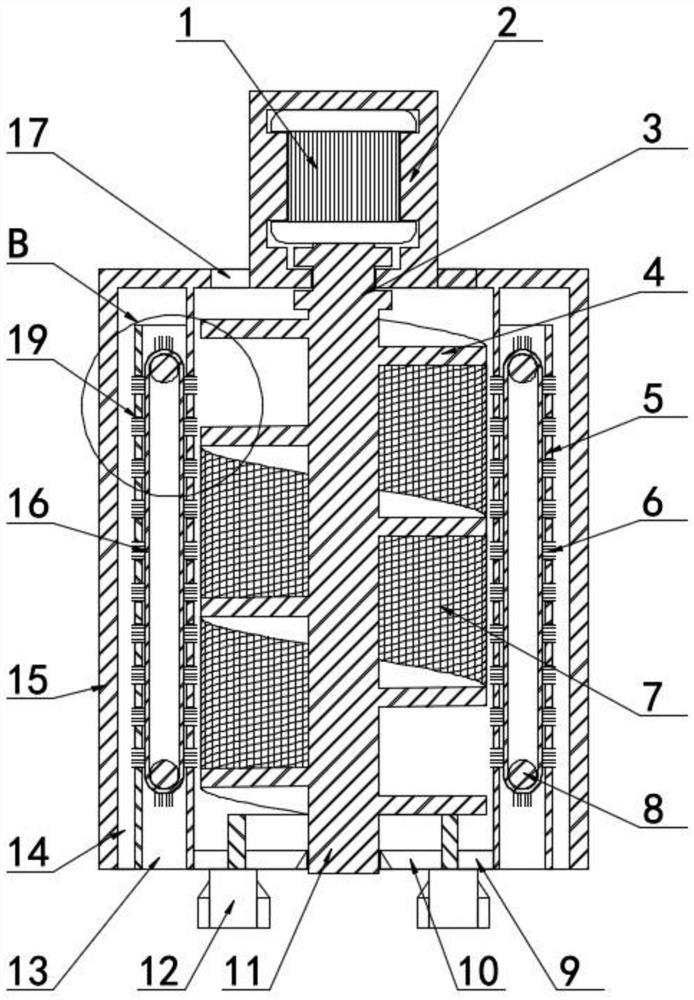

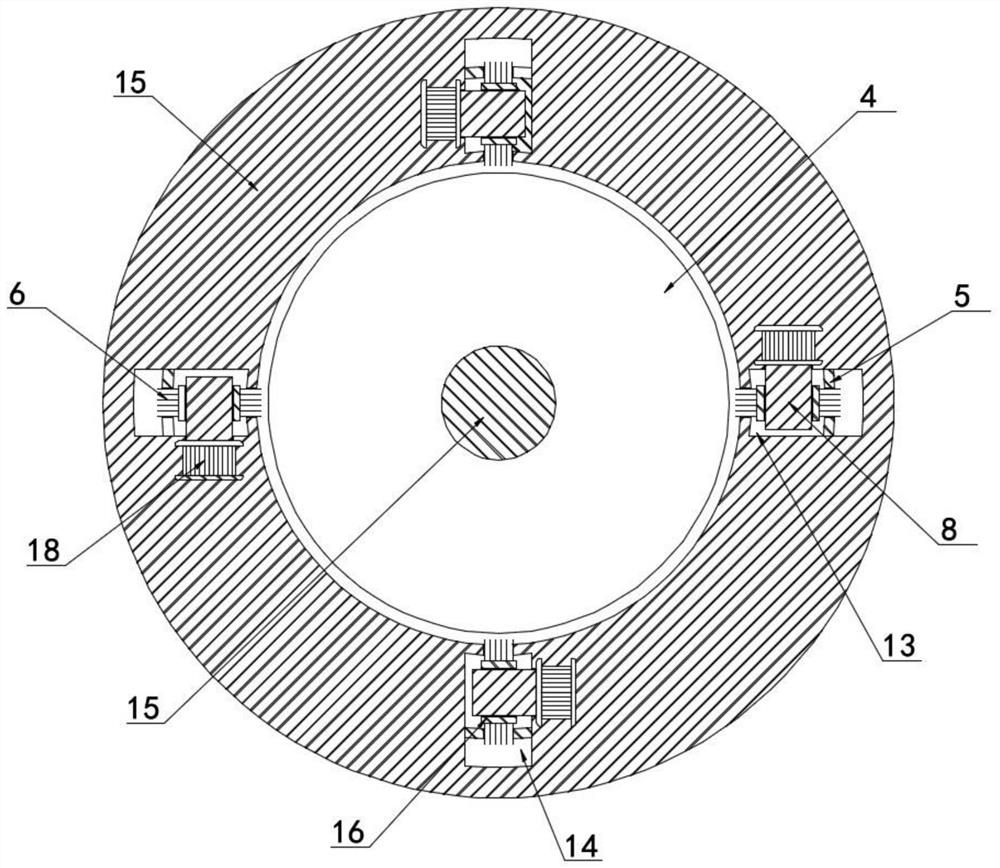

[0034] Embodiment one, with reference to Figure 1-5, a raw material cleaning device in the Poria cocos extract process, comprising a cylindrical support shell 15 and a support foot 12 fixedly connected to the bottom end of the cylindrical support shell 15, the top center of the cylindrical support shell 15 The upper driving pair fixed opening shell 2 is fixedly connected, and the upper driving pair fixed opening shell 2 is fixedly connected with the first driving pair 1, the output end of the first driving pair 1 is fixedly connected with the central rotating shaft 11, and the outer side of the central rotating shaft 11 is fixedly connected with the inner The spiral centrifugal separation disc 4, the outer side wall of the inner spiral centrifugal separation disc 4 is fixedly connected with the outer spiral isolation separation net 7, and the side wall of the cylindrical support shell 15 is provided with at least one waste material mixed liquid impurity outlet cavity 13 and an...

Embodiment 2

[0035] Embodiment 2, refer to Figure 1-5 At least one second drive pair 18 is fixedly connected to the inner cavity of the cylindrical support shell 15, and one drive shaft 8 in the two drive shafts 8 is fixedly connected to the output end of the second drive pair 18, and the liquid injection flushes the liquid inlet 14 The top is connected to the top of the waste mixed liquid impurity outlet cavity 13, and a central isolation barrier 5 is arranged between the liquid injection flushing inlet 14 and the waste mixed liquid impurity outlet cavity 13, and the central isolation barrier 5 is fixed to the cylindrical support shell 15. connection, the bottom end of the cylindrical support shell 15 is provided with an internal impurity downward guide opening groove 10 and a separated poria cocos discharge port 9, and the top of the internal impurity downward guide opening groove 10 is in clearance fit with the bottom end of the internal spiral centrifugal separation disc 4, The inner ...

Embodiment 3

[0036] Embodiment 3, refer to Figure 1-5 , the opening of the fixed opening shell 2 of the upper driving pair is radially screwed and connected with an I-shaped limit turntable 3, and the I-shaped limit turntable 3 is axially clamped with the opening of the upper drive pair fixed open shell 2, and the I-shaped limit The rotary disk 3 is fixedly connected to the top of the central rotating shaft 11, at least one waste material mixed liquid impurity outlet port 13 and the bottom end of the injection flushing liquid inlet 14 all pass through the bottom side wall of the cylindrical support shell 15, and the inner spiral centrifugal separation disc 4 The upper and lower ends are all parallel to the horizontal plane, and the opening at the top of the cavity between the inner helical centrifugal separation disc 4 and the outer helical isolation separation net 7 communicates with the Poria cocos raw material separation inlet 17, and the inner helical centrifugal separation disc 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com