Nano polyhedral ferric vanadate film photoelectrode with visible light response and preparation method and application thereof

A technology of thin film electrodes and polyhedrons, which is applied in the field of nano-polyhedral iron vanadate thin film photoelectrodes and its preparation, can solve the problems of unfavorable electron/hole pair separation and interface charge transport, poor charge transport ability, and small space charge density. Achieve excellent photocatalytic performance, high degradation rate, uniform dispersion of nanostructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a nano-polyhedron iron vanadate film photoelectrode responsive to visible light, comprising the following steps:

[0036] (1) Iron salt is mixed with alkali metal nitrate, water and acid to obtain a mixed solution;

[0037] (2) carrying out the hydrothermal reaction with the mixed solution obtained in the step (1) to obtain the FeOOH film electrode;

[0038] (3) coating the vanadium source solution on the FeOOH film electrode obtained in the step (2) and performing heat treatment to obtain a nano-polyhedron iron vanadate film photoelectrode.

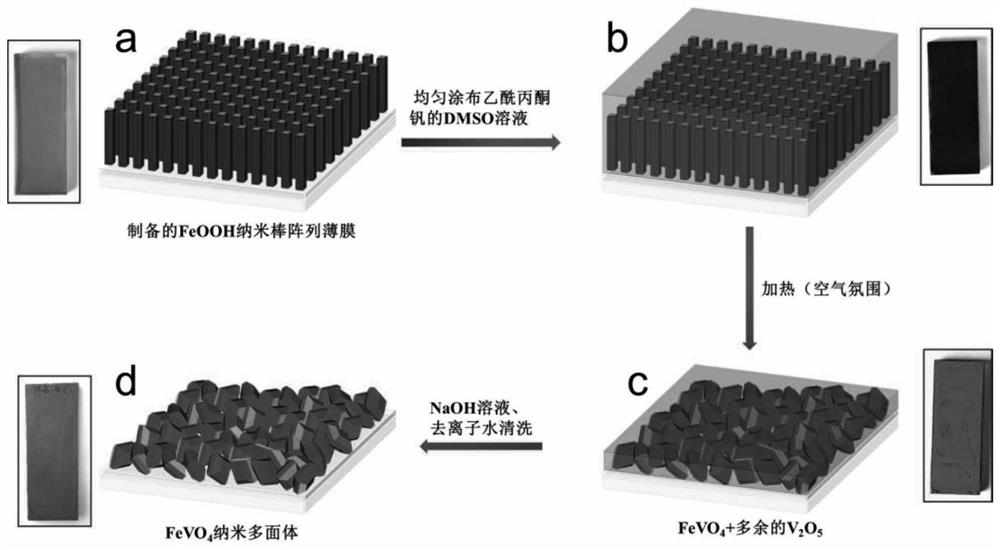

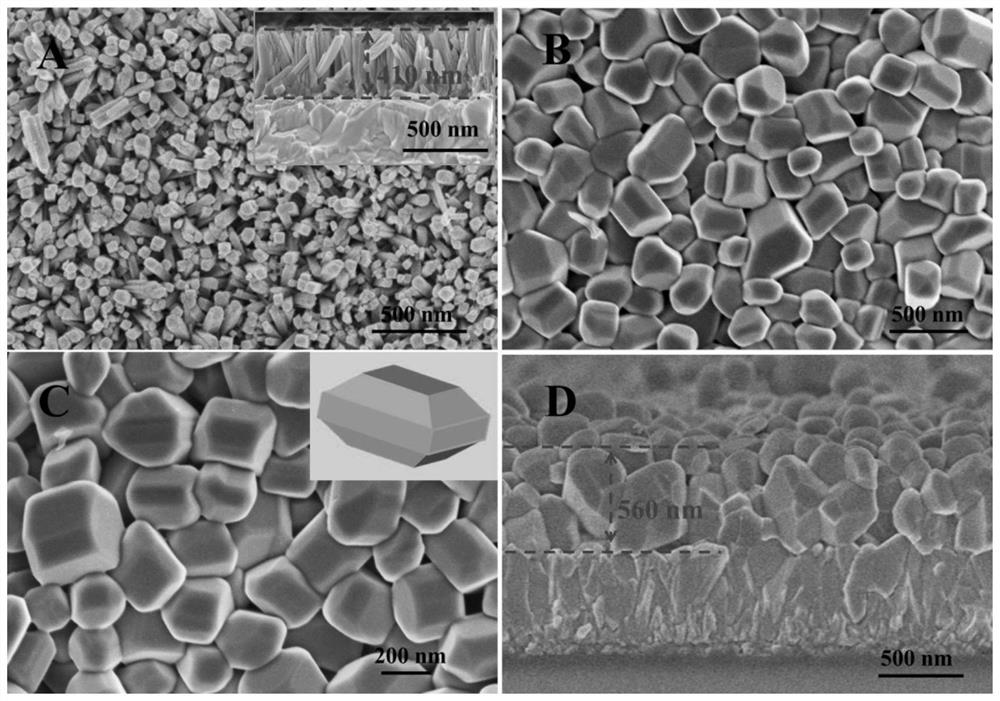

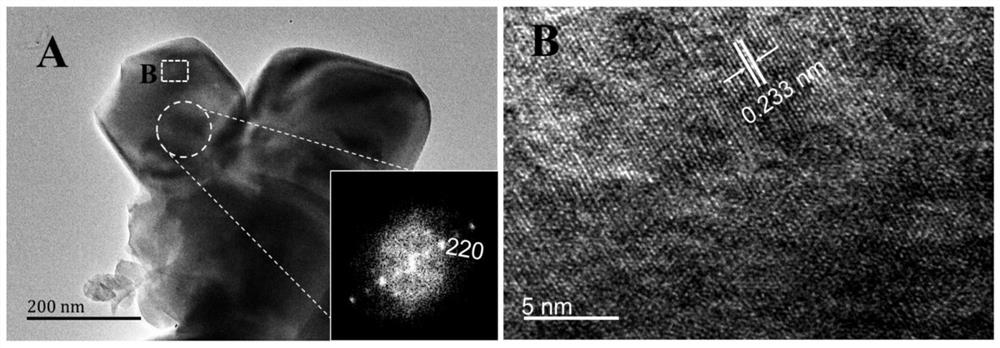

[0039] Such as figure 1 As shown, the flow process of the preparation method of the nano-polyhedral iron vanadate thin film photoelectrode of the visible light response provided by the present invention is to first prepare the FeOOH nanorod array film, then coat the vanadium source solution and carry out heat treatment to obtain iron vanadate and vanadium pentoxide, After being washe...

Embodiment 1

[0080] (1) 75mmol FeCl 3 ·6H 2 O and 0.5mol sodium nitrate were dissolved in 70mL of deionized water, and hydrochloric acid was added dropwise to adjust the pH to 1.5 to obtain a mixed solution (FeCl 3 ·6H 2 The ratio of the amount of O and sodium nitrate is 0.15:1, FeCl 3 ·6H 2 The volume ratio of the amount of O substance to deionized water is 7.5mmol: 7mL);

[0081] (2) Transfer the mixed solution obtained from the step (1) to the reaction kettle with the conductive side of the cleaned 3cm×3cm FTO conductive glass facing down, and conduct a hydrothermal reaction at 100°C for 6h, cool to room temperature naturally, and wash with water And dry, obtain FeOOH film electrode;

[0082] (3) The dimethyl sulfoxide solution of 0.18mL 0.1mol / L vanadium acetylacetonate is uniformly drip-coated on the FeOOH film electrode (the ratio of the surface area of the dimethyl sulfoxide solution of vanadium acetylacetonate to the FTO conductive glass is 0.02mL : 1cm 2 ), dried on a fla...

Embodiment 2

[0094] (1) 75mmol FeCl 3 ·6H 2 O and 0.5mol sodium nitrate were dissolved in 70mL of deionized water, and hydrochloric acid was added dropwise to adjust the pH to 1.5 to obtain a mixed solution (FeCl 3 ·6H 2 The ratio of the amount of O and sodium nitrate is 0.15:1, FeCl 3 ·6H 2 The volume ratio of the amount of O substance to deionized water is 7.5mmol: 7mL);

[0095] (2) Transfer the mixed solution obtained from the step (1) to the reaction kettle with the conductive side of the cleaned 3cm×3cm FTO conductive glass facing down, and conduct a hydrothermal reaction at 100°C for 1 hour, cool to room temperature naturally, and wash with water And dry, obtain FeOOH film electrode;

[0096] (3) The dimethyl sulfoxide solution of the vanadium acetylacetonate of 0.01mol / L is uniformly drip-coated on the FeOOH film electrode (the ratio of the volume of the dimethyl sulfoxide solution of vanadium acetylacetonate to the surface area of the FTO conductive glass is 0.01mL: 1cm 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com