Convenient stir-frying equipment for processing trichosanthes kirilowii maxim seeds

A kind of convenient technology for trichosanthes seeds, which is applied in the field of convenient frying equipment for the processing of trichosanthes seeds, can solve the problems of low efficiency and manpower consumption, and achieve the effects of improving efficiency, stable operation of the device, and uniform taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

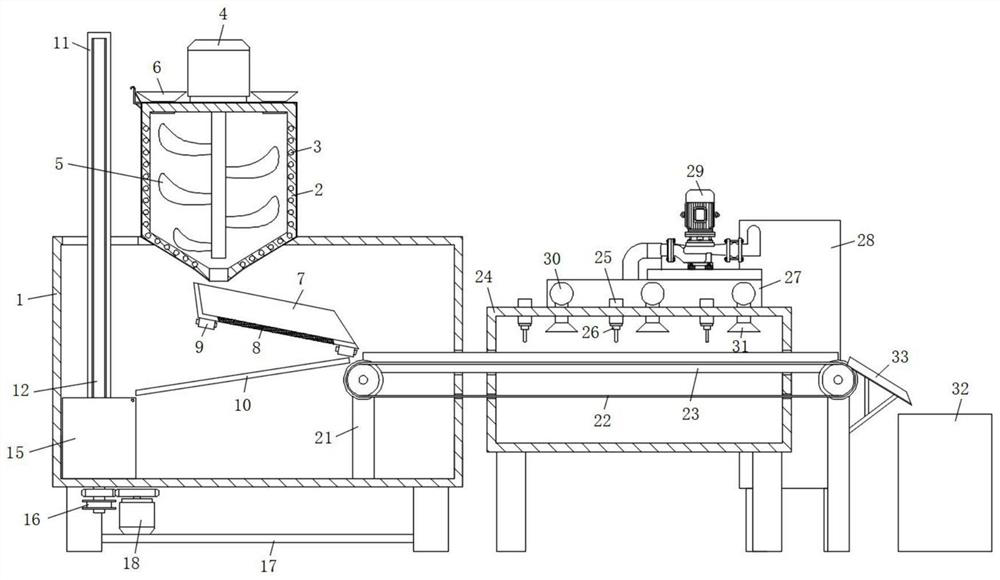

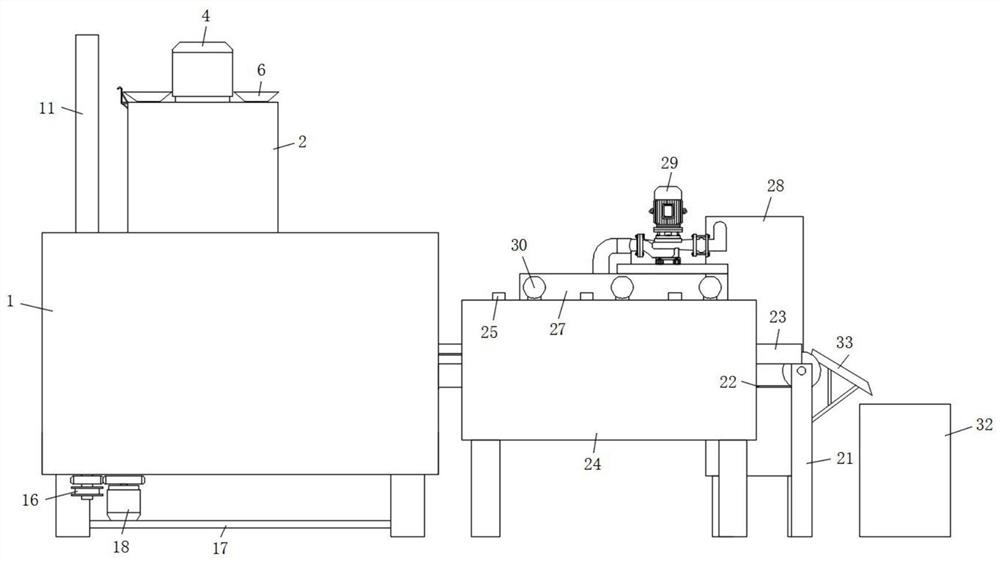

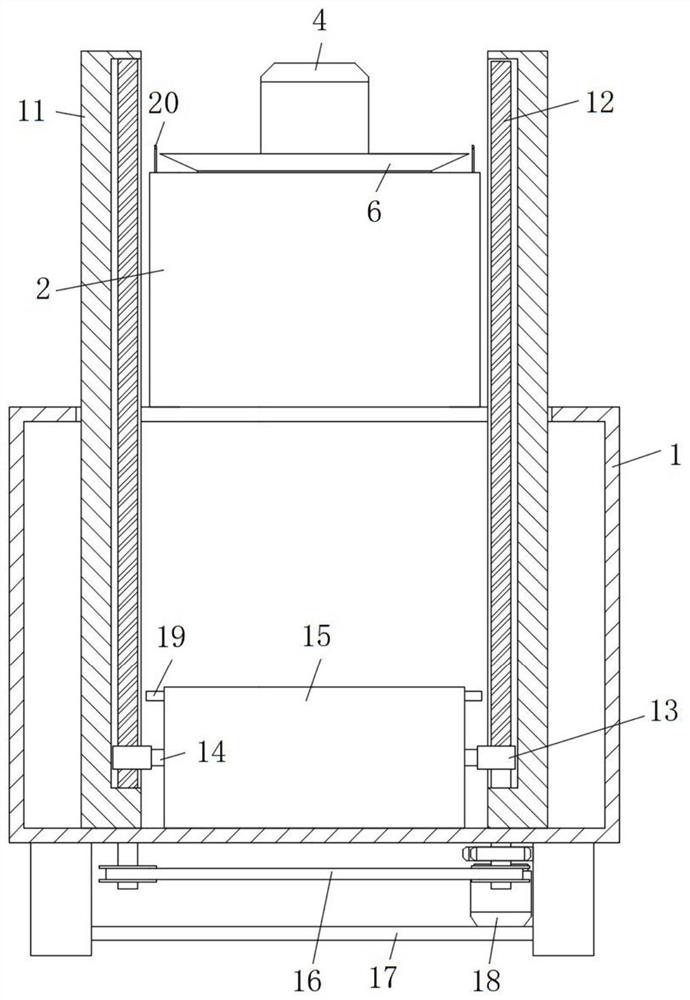

[0028] refer to Figure 1-4, a kind of convenient frying equipment for processing Trichosanthes seeds, comprising a screening dish 1, four corners of the bottom surface of the screening dish 1 are fixed with supports, the middle part of the top surface of the screening dish 1 is provided with a mounting hole, and the inner wall of the mounting hole passes through The screw is fixed with the frying tube 2, the inner wall of the frying tube 2 is installed with the heating tube 3, the middle part of the outer top surface of the frying tube 2 is fixed with the servo motor 14 through the screw, and the output end of the servo motor 14 passes through the frying tube. Stir-fry blades 5 are fixed on the top surface of the barrel 2, and the top surface of the frying barrel 2 is connected with a feeding dish 6 through both sides, and a discharge hole is opened through the middle part of the bottom end of the frying cylinder 2, and a stopper is installed on the inner wall of the discharge...

Embodiment 2

[0030] Such as figure 1 , 2 As shown in and 3, this embodiment is basically the same as Embodiment 1. Preferably, the air-cooled impurity removal mechanism includes a mounting base 21, a conveyor belt 22 is fixedly installed on the upper end of the mounting base 21, and baffles 23 are arranged on the front and rear sides of the conveyor belt 22. The central part of 22 is also provided with a condensate removal box 24, and both sides of the condensation removal box 24 are provided with strip grooves, and the conveyor belt 22 is placed in the strip groove, and the top surface of the condensation removal box 24 is also provided with a cylindrical hole. The inner walls of the cylindrical holes are fixed with electric telescopic rods 25 by screws, and the output ends of the two electric telescopic rods 25 in the same group are fixed with dispersing components 26, and a hollow dish 27 is also fixed on the rear side of the top surface of the condensate removal miscellaneous box 24, a...

Embodiment 3

[0035] Such as figure 1 and 2 As shown, the present embodiment is basically the same as Embodiment 2. Preferably, a plurality of dust suction pipes 30 are arranged and evenly distributed on the front side wall of the hollow dish 27, and a plurality of suction funnels 31 are arranged and evenly distributed on the On the bottom surface of the dust suction pipe 30 , the material guide plate 33 is fixed on the side wall of the mounting base 21 .

[0036] In this embodiment, there are multiple ash suction pipes 30 and material suction funnels 31, so as to realize the comprehensive suction of the hot air of the Trichosanthes seeds and the complete removal of impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com