Preparation method of hsian-tsao gum-surimi composite gel

A technology of jelly jelly gum and composite gel, which is applied in the direction of food ingredients as gelling agent, food ingredient as taste improver, food ingredients containing natural extracts, etc., can solve the problems of changing the texture and taste of composite gel, etc. To achieve the effect of weakening hydrophobic interaction, broadening the application range and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

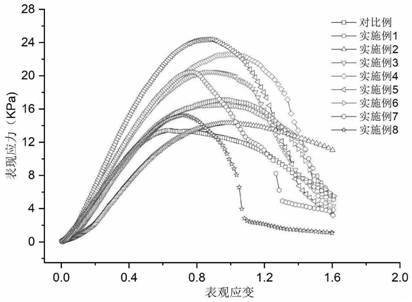

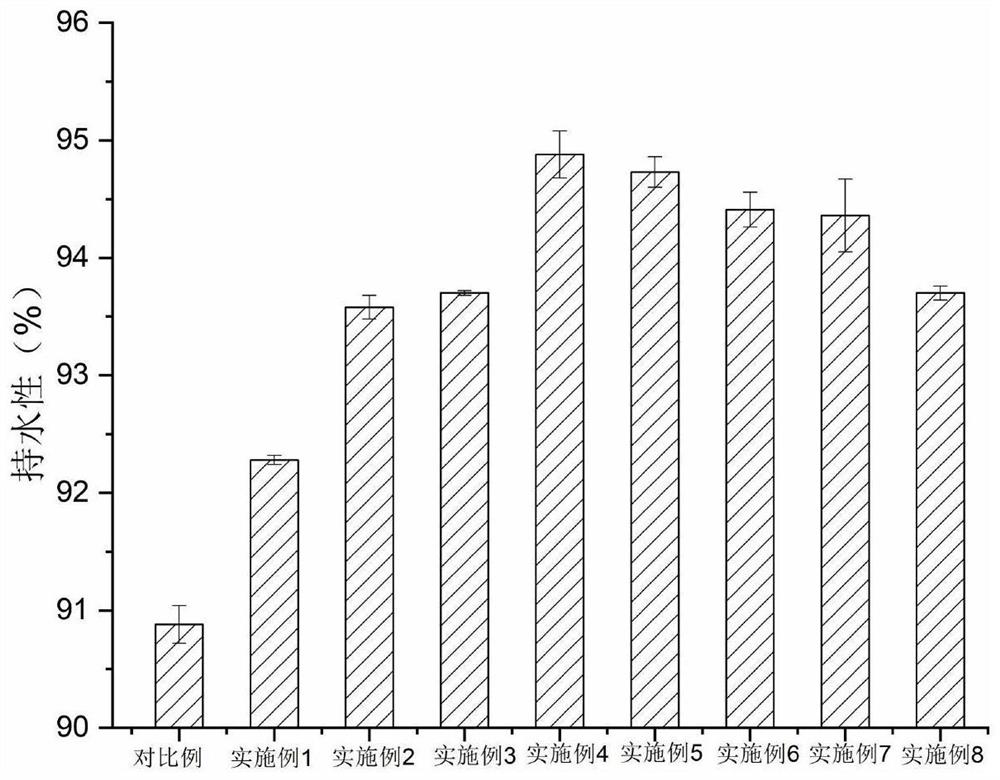

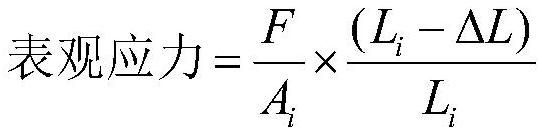

Examples

preparation example Construction

[0033] A preparation method for jelly jelly gum-surimi composite gel, comprising the steps of:

[0034] Step 1) Empty chopping: Mix fresh surimi or frozen surimi (thawed at 4°C) with ice water and chop (100-1000rpm, 1-3min);

[0035] Step 2) Salt chopping: add edible salt according to the recipe and continue chopping (1000-5000rpm, 4-7min);

[0036] Step 3) Mix and chop: Add jelly gum and citric acid according to the recipe, chop and mix evenly (1500-4000rpm, 5-10min), finally add starch, moisture retention agent and seasoning, chop and mix well (1500-4000rpm, 2~5min);

[0037] Step 4) Forming: heat the compound prepared in step (3) at 20-45°C for 1-2 hours, and gelatinize at low temperature; after the compound is formed, heat it at 90-100°C for 20-60 minutes, and cook at high temperature; After cooling in the bath, it is cooled at 0-4° C. for 4-10 hours to obtain a composite surimi gel product with good texture and sensory properties.

[0038] The addition amount of variou...

Embodiment 1

[0049] A kind of jelly jelly gum-surimi composite gel product, comprising the following components: by mass percentage of surimi, jelly jelly gum 0.3%, edible salt 2%, starch 0.5%, citric acid 0.3%, moisture retaining agent 0.1% , seasoning 5%, ice water 5%.

[0050] The preparation method of described jelly gum-surimi composite gel, comprises the steps:

[0051] Step 1) Empty chopping: Weigh 200.00g of fresh surimi or frozen surimi (thawed at 4°C) and mix with 8.00g of ice water for chopping (500rpm, 2min);

[0052] Step 2) Salt chopping: add 4.00g of edible salt and continue chopping (4500rpm, 6min);

[0053] Step 3) Mixing and chopping: Weigh 0.60g jelly gum, 0.60g citric acid and dissolve in 2.00g ice water, add to the surimi prepared in step 2), chop and mix evenly (4500rpm, 6min), and finally add 1.00g Starch, 0.20g moisture retaining agent and 10.00g seasoning, chopped and mixed evenly (4000rpm, 4min).

[0054] Step 4) Forming: heat the compound prepared in step 3) a...

Embodiment 2

[0055] Embodiment 2: [step 1), 2), 4) with embodiment 1]

[0056] A kind of jelly jelly gum-surimi composite gel product, comprising the following components: in terms of surimi mass percentage, jelly jelly gum 0.5%, edible salt 2%, starch 0.5%, citric acid 0.3%, moisture retaining agent 0.1% , seasoning 5%, ice water 5%.

[0057] The preparation method of described jelly gum-surimi composite gel, comprises the steps:

[0058] [step 1), 2), 4) with embodiment 1]

[0059] Step 3) Mixing and chopping: Weigh 1.00g jelly gum, 0.60g citric acid and dissolve in 2.00g ice water, add to the surimi prepared in step 2), chop and mix evenly (4500rpm, 6min), and finally add 1.00g Starch, 0.20g moisture retaining agent and 10.00g seasoning, chopped and mixed evenly (4000rpm, 4min).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com