Spliced mirror pose test system and method based on scanning galvanometer

A scanning galvanometer and testing system technology, applied in the field of active optics, can solve problems such as difficulty in adjusting the mirror position and attitude of the optical path system, increase the overall system error, reduce system stability, etc., so as to be beneficial to test control and reduce the overall error. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

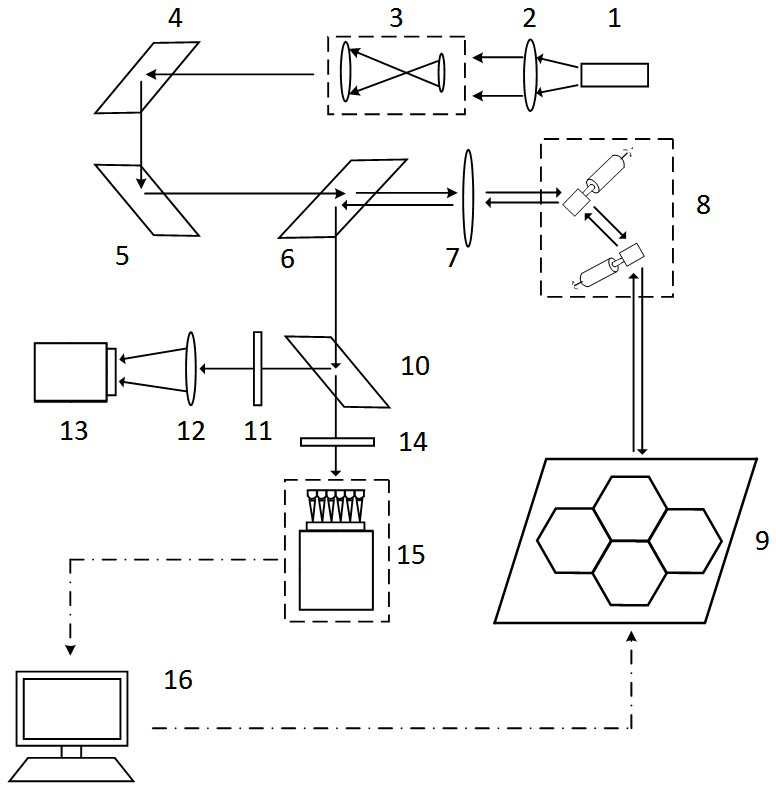

[0047] See figure 1 , a scanning galvanometer-based splicing mirror pose test system, the test system includes a transmitting unit, a receiving unit, a detection unit and a correction unit;

[0048] The launch unit includes,

[0049] The laser transmitter 1 is used to generate the coherent light source required in the pose test system, and the coherent light source is divergent light,

[0050] The first lens 2 is used to receive divergent light and refract the divergent light into parallel light,

[0051] The beam expander 3 is used to amplify the beam diameter of the parallel light in proportion to obtain the expanded beam,

[0052] The first reflector 4 and the second reflector 5 are used together to change the propagation direction of the beam expansion light, and are combined with the double diaphragm to collimate the beam expansion light to obtain collimated beam expansion light;

[0053] The receiving unit consists of,

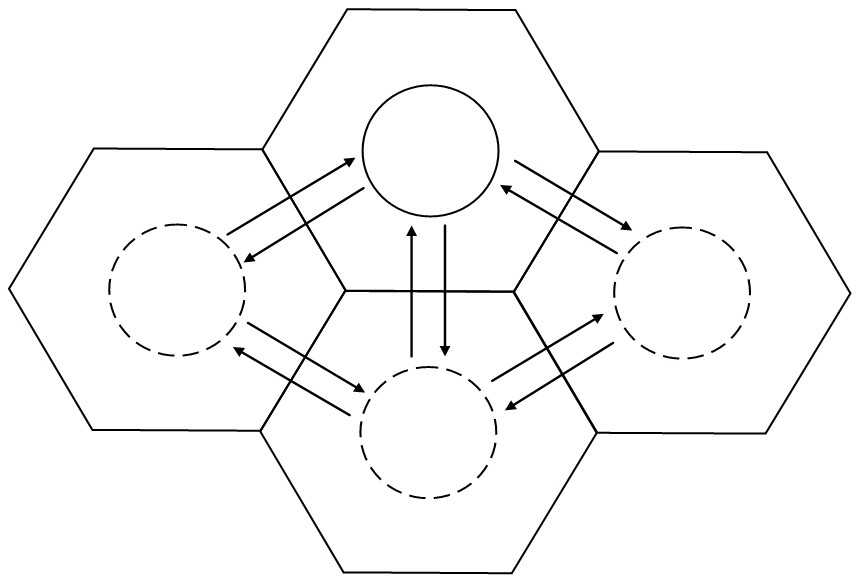

[0054] The splicing reflector 9 is spliced b...

Embodiment 2

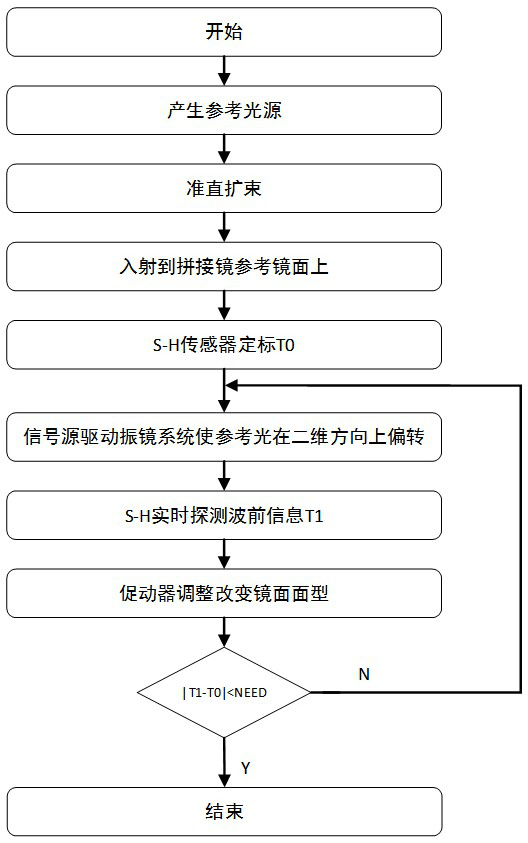

[0069] See image 3 , the flow chart of the test method of the above-mentioned splicing mirror pose test system,

[0070] The test method of the above-mentioned reflector space pose test system comprises the following steps:

[0071] Step 1): The emitting unit emits collimated beam expansion light,

[0072] Step 2): A splicing mirror of the receiving unit receives the collimated and expanded beam and returns according to the original path to obtain reflected light.

[0073] Step 3): The detection unit receives the reflected light of the splicing mirror to obtain the reference wavefront phase information, and stores the reference wavefront phase information,

[0074] Step 4): Based on the reference wavefront phase information, the correction unit uses the mode method in the wavefront restoration algorithm to calculate the value of the corresponding coefficient of the Zernike polynomial, and fine-tune the pose of the above-mentioned splicing mirror until the inclination and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com