Acid-soluble drilling drainage structure of karst or faulted tunnel and side slope and construction method

A drainage structure and fault technology, which is applied in the direction of infrastructure engineering, tunnels, drainage, etc., can solve the problem of not being able to isolate the grout, and achieve a high filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below.

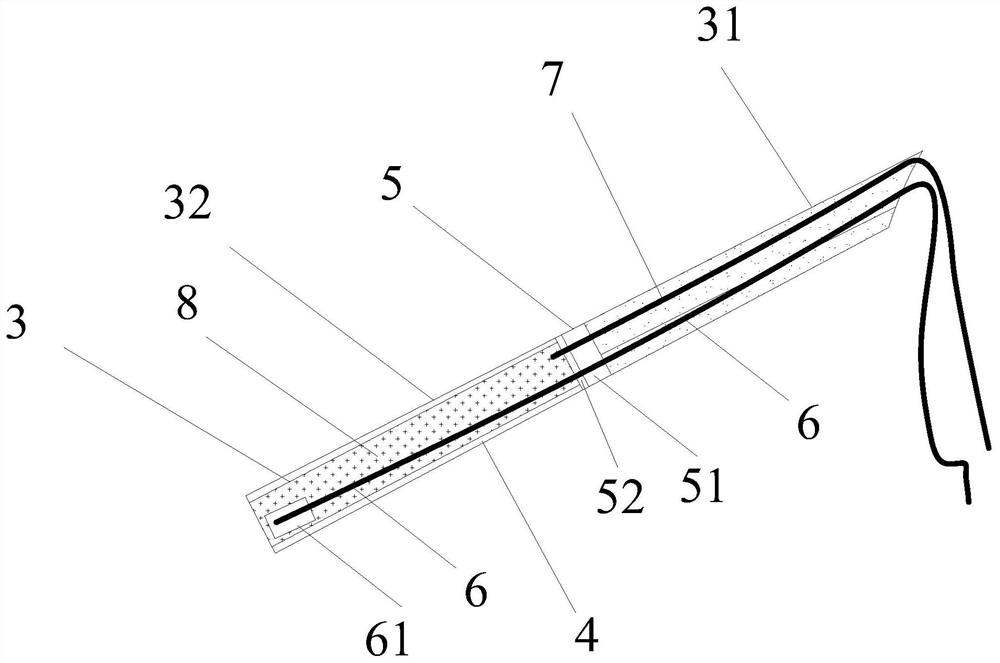

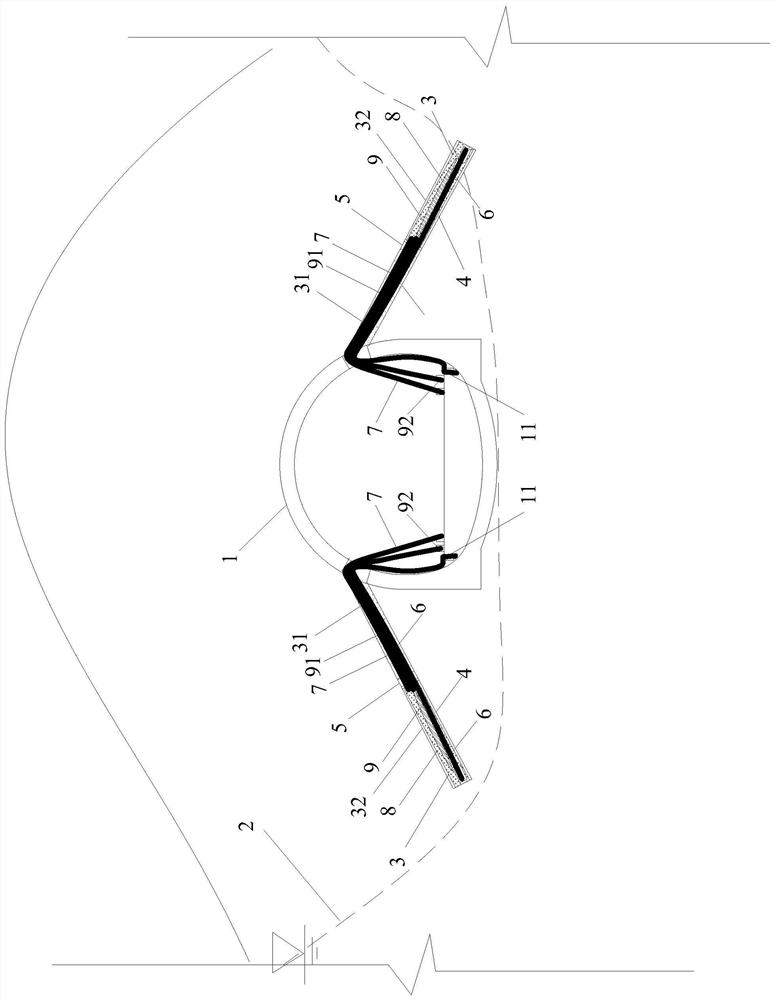

[0043] The drainage structure of acid-soluble borehole 3 for karst or faulted tunnels and slopes disclosed by the present invention includes a hollow section 32 and a grouting section 31, and the hollow section 32 is located at the lower part of the downdipping borehole 3. The grouting section 31 is located at the upper part of the borehole 3, a water-stop member 5 is arranged between the permeable section and the grouting section 31, a permeable pipe 4 is arranged in the permeable section, and a cavity is provided in the permeable pipe 4. The water-permeable pipe 4 is provided with a drain pipe 6 extending outward through the water-stop member 5, and the water-permeable pipe 4 is filled with an acid-soluble and water-insoluble solid filling material 8, and the water-stop member The lower part of 5, the permeable pipe 4 and the drain pipe 6 are all acid-resistant materials or have an acid-resistant surface layer to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com