Automatic glazing process for spark plug ceramic parts

A technology for automatic glazing and ceramic parts, which is applied in ceramic molding machines, manufacturing tools, etc., and can solve problems such as glaze sticking and ceramic parts touching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

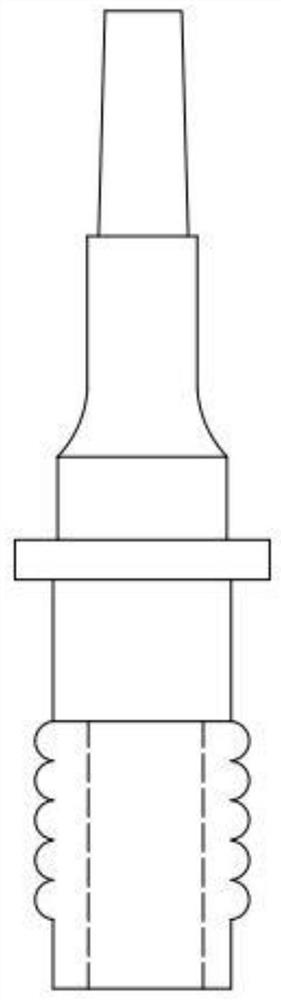

[0034] Such as figure 1 , figure 2 , Figure 7 and Figure 8 Shown, the technical scheme that the present invention takes is as follows:

[0035] 1) Pour the spark plug ceramic parts to be glazed into the vibrating feeding tray machine 100, and the disc body of the vibrating feeding tray machine rotates, and the materials are arranged in sequence and discharged from the discharge port;

[0036] 2) After entering the vibration channel, the ceramic part of the spark plug will be mounted on the top of the feed tank and move forward with the vibration, and then the seal will come to the automatic insertion plate 200 along with the vibration channel, and the ceramic part of the spark plug will move into the slot, and then The ceramic piece will start to rotate with the automatic insertion disc.

[0037] 3) With the rotation of the automatic insertion disk, the spark plug ceramic part automatically enters the glazer 300;

[0038] A vibrating channel 400 is erected between the vi...

Embodiment 2

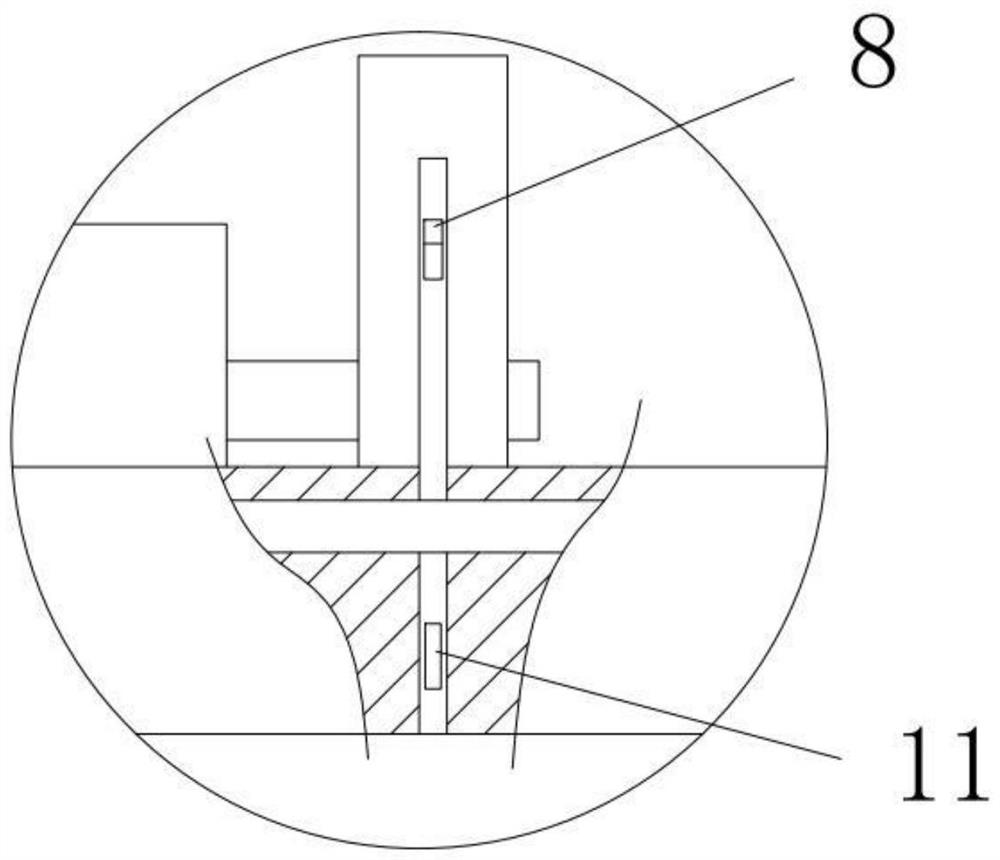

[0041] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 9 and Figure 10 As shown, the difference between the present embodiment 2 and the implementation 1 is that a driving motor 500 is installed above the feeding chute, and the output shaft of the driving motor is equipped with a gear 4, and the left and right sides of the gear are equipped with gears respectively. The meshed upper rack 5 and the lower rack 6, the top of the upper rack is connected with the upper fixed rod 7, the top of the upper fixed rod is connected with a horizontal upper cross bar 8, and the end of the upper cross bar is equipped with a lower Extrusion block 9, the bottom of the lower rack is equipped with a lower fixed rod 10, the lower fixed rod is equipped with a lower cross bar 11, the end of the lower cross bar is equipped with a flange 12, and the lower cross bar is equipped with a A sliding baffle 13, a spring 14 is arranged between the lower cross bar and the baffle, a plurali...

Embodiment 3

[0048] The difference between this embodiment 3 and implementation 2 is that the glazing machine includes a large disk, and several bearing seats are arranged on the edge of the disk, and the driving parts are also embedded on the disk, and the bearing seats are arranged in sequence. On the driving part, the driving part is driven by the driving motor to rotate relative to the disc, and the seat starts to rotate with the driving part, and the ceramic part sleeved in the seat rotates accordingly.

[0049] When the ceramic piece rotates with the seat to the spraying section in front of the spray gun, the spray gun starts to work, and the glaze is sprayed to the glazed part of the ceramic piece. There are glaze basins on the front and rear sides of the glaze spraying section to catch the excess. The glaze is convenient for subsequent cleaning and recycling; and because the seat and the driving part are rotatably connected, a ring of gears protrudes from the outer side of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com