System for managing a reagent dispensing device in an exhaust line

A technology for exhaust pipelines and reactants, which can be used in exhaust treatment, electronic control of exhaust treatment devices, transmission systems, etc., and can solve problems such as changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

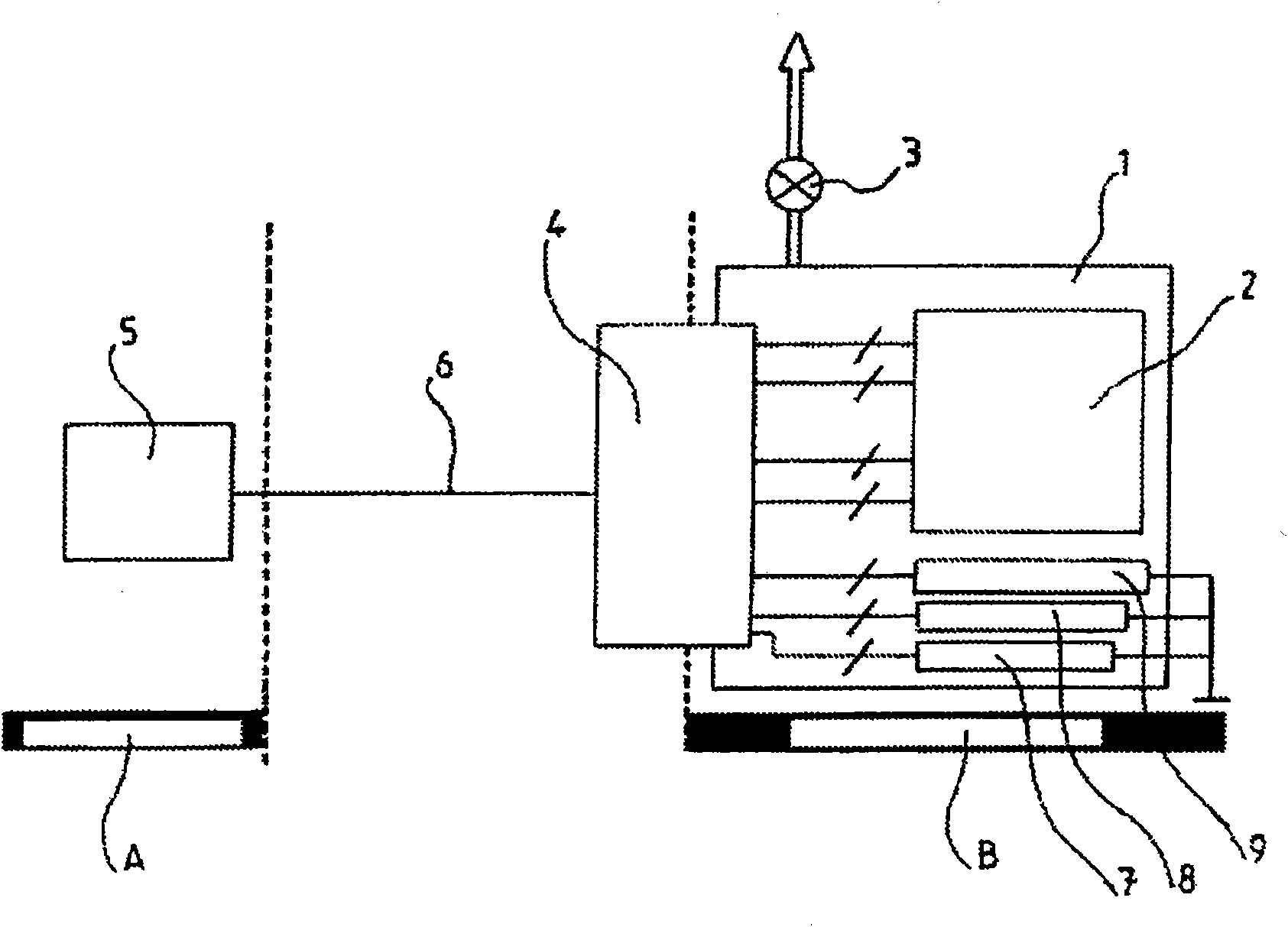

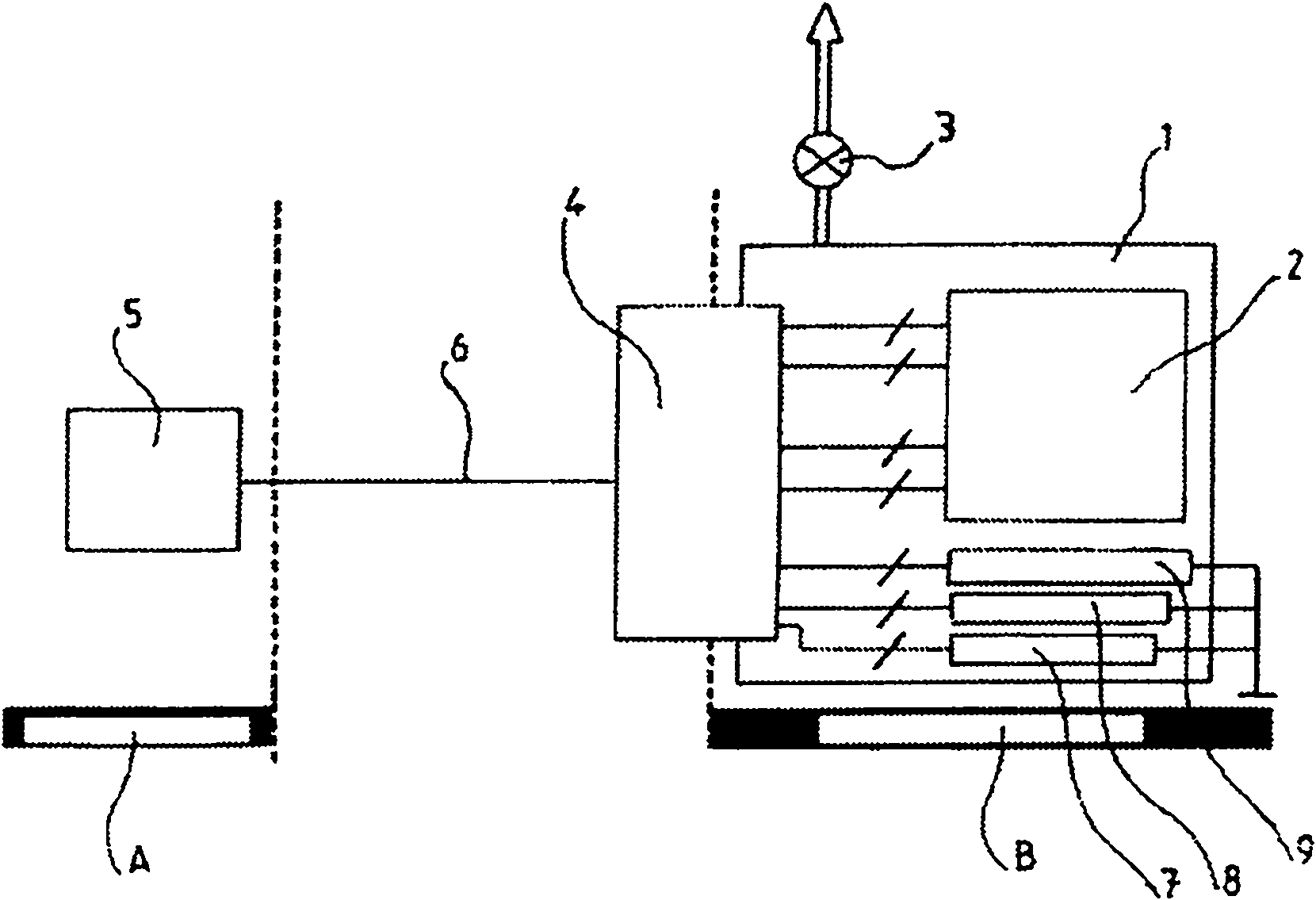

[0030] The distribution circuit comprises a container 1 for quantitatively injecting reactants into the exhaust gas. For the catalytic reduction of NOx with the SCR, the container has a volume of about 25 liters, about the volume of a wheel, and is located away from the underhood area (engine compartment), for example, near the trunk or in zone B therein.

[0031] This distribution circuit comprises injection means 3 capable of extracting a quantity of reactant in container 1 and injecting it into the exhaust gas. For this purpose, the injection device 3 comprises, for example, a metering pump, controlled according to the pressure demand in the injection circuit; and nozzles, which inject the required amount of reactant. exist figure 1 In , the sending of a portion of the reactants to the point where they are injected into the exhaust is indicated by the arrow symbol from pump 3 .

[0032] As mentioned above, the reactant is based on urea which freezes at -11°C, so the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com