Precious metal vacuum bead scattering machine

A precious metal and vacuum technology, applied in the field of jewelry processing equipment, can solve the problems of poor quality of finished products, uneven particle size of metal beads, etc., and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

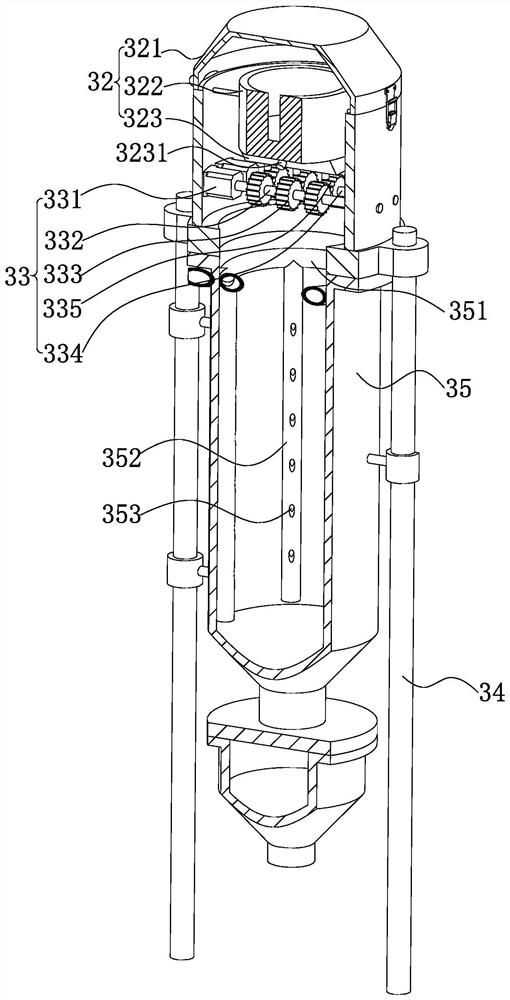

[0037] The following is attached Figure 1-3 The application is described in further detail.

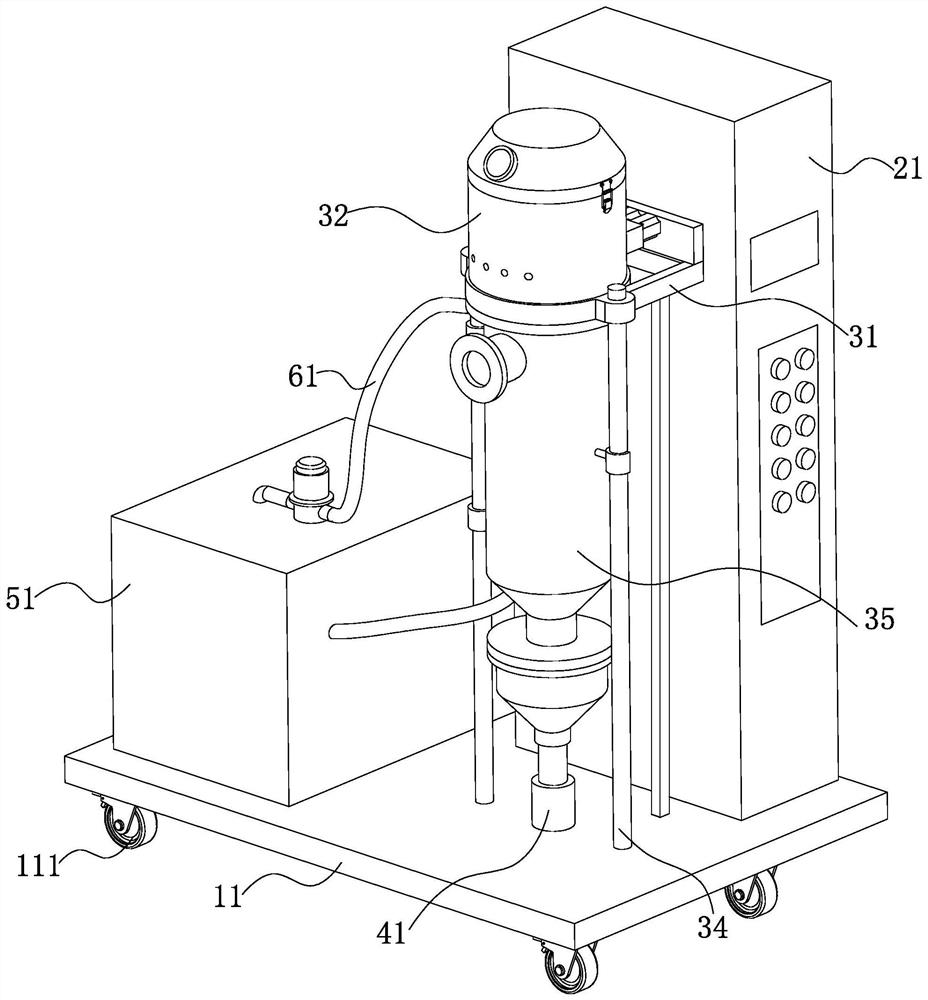

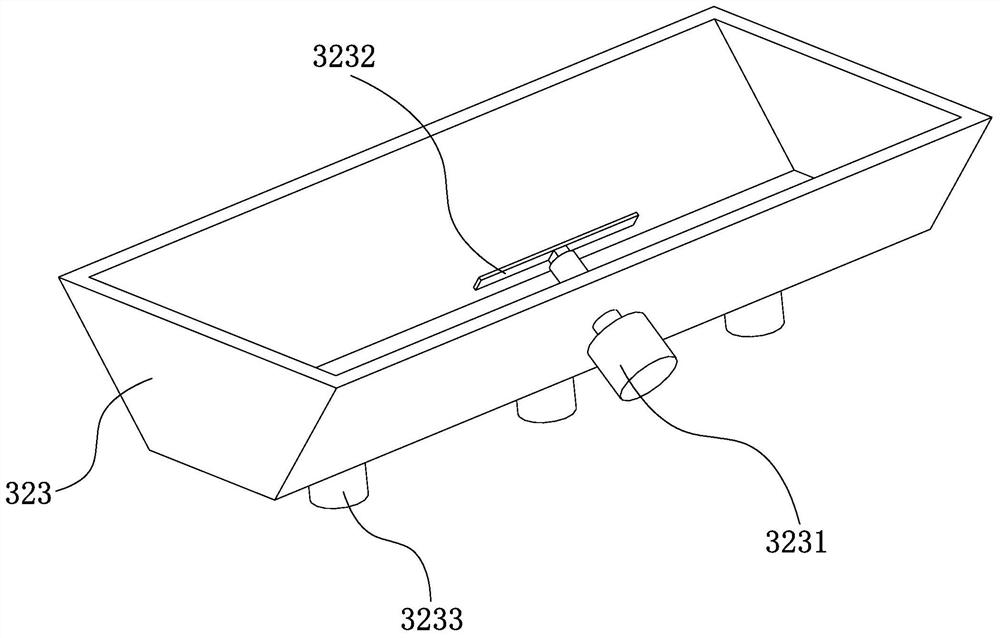

[0038] The embodiment of the present application discloses a precious metal vacuum bead scattering machine. refer to figure 1 with figure 2 , the precious metal vacuum sprinkler host includes a base 11, an electric control cabinet 21, a mounting frame 31, a vacuum melting furnace 32, a quantitative granulation device 33, a column 34, a material receiving bucket 35, a hydraulic cylinder 41, a water cooling device 51 and a water pipe 61. Wherein, the electric control cabinet 21 is installed on the base 11, the mounting frame 31 is arranged on the upper surface of the base 11, the mounting frame 31 is vertically arranged on the upper surface of the base 11, and the mounting frame 31 is used for installing the vacuum melting furnace 32, quantitative manufacturing The granulation device 33 is set in the vacuum melting furnace 32, the column 34 is set on the mounting frame 31, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com