Smooth rectangular soldering tin sheet preparation system and preparation method

A technology for preparing a system and a solder sheet, which is applied in the direction of metal extrusion dies, etc., can solve the problem that the solder sheet cannot reach a complete plane, etc., so as to reduce personnel requirements and industrial safety incidents, reduce oxide production, and improve the stability of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

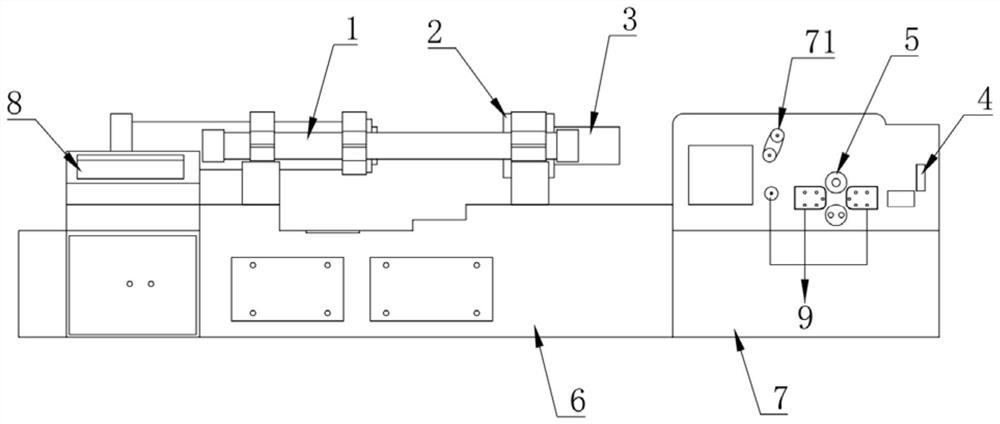

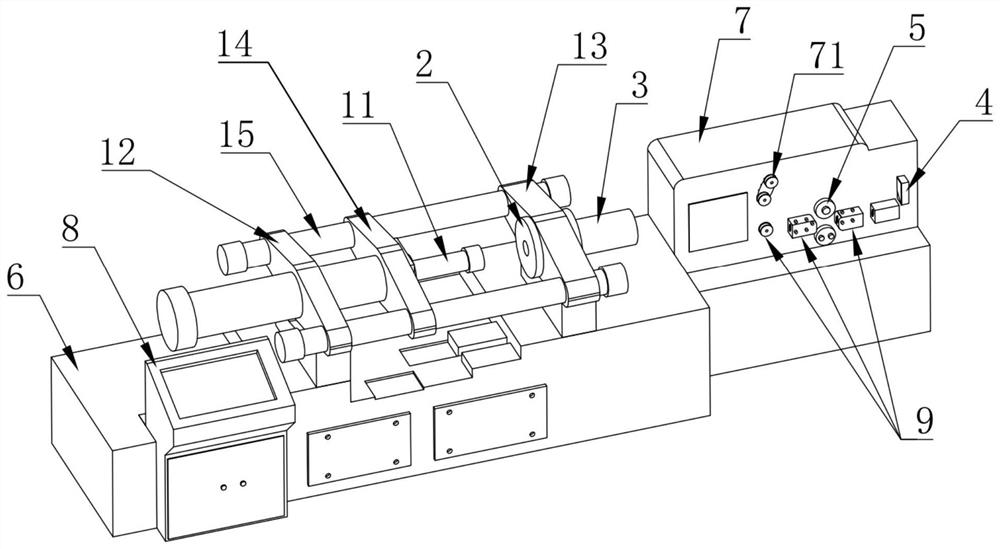

[0031] Such as figure 1 and figure 2 As shown, the present invention provides a flat rectangular solder sheet preparation system, which includes a pushing mechanism 1 , a heating device 2 , a rectangular hole mold 3 and a shearing mechanism 4 arranged in sequence from left to right. On the side of the pushing mechanism 1, the heating device 2 is provided with a feeding port for putting tin pillars into and softening. The rectangular hole mold 3 is fixed on the heating device 2, and the rectangular hole mold 3 is provided with a discharge port on the side of the shearing mechanism 4, and the discharge port is connected to the feed port. The pushing mechanism 1 includes an extruding shaft 11 for extruding the tin column from the heating device 2 to the rectangular hole mold 3 . And between the heating device 2 and the shearing mechanism 4, a feeding mechanism 5 for guiding the shaped rectangular soldering wire to the shearing mechanism 4 is provided. Therefore, the tin mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com