Treatment method and device for solid coking materials formed in fixed bed catalytic reaction

A fixed bed reactor and catalytic reaction technology, applied in the field of chemical cleaning, can solve the problems of poor treatment effect, poor coke effect, and long treatment period of coke, so as to avoid damage and improve the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

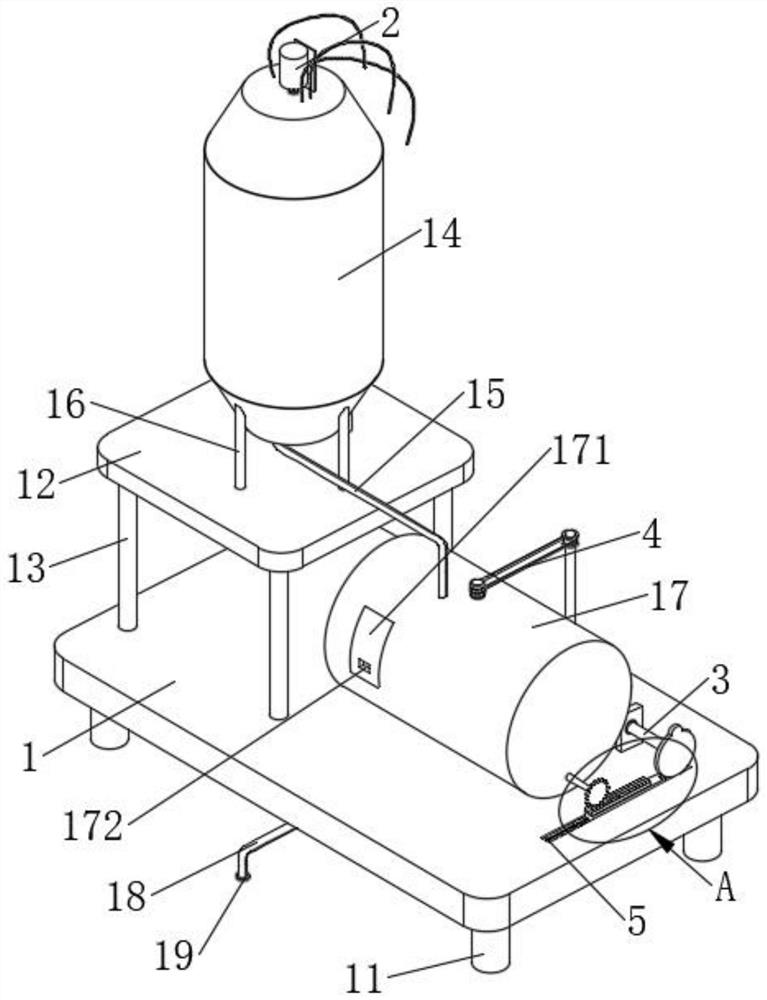

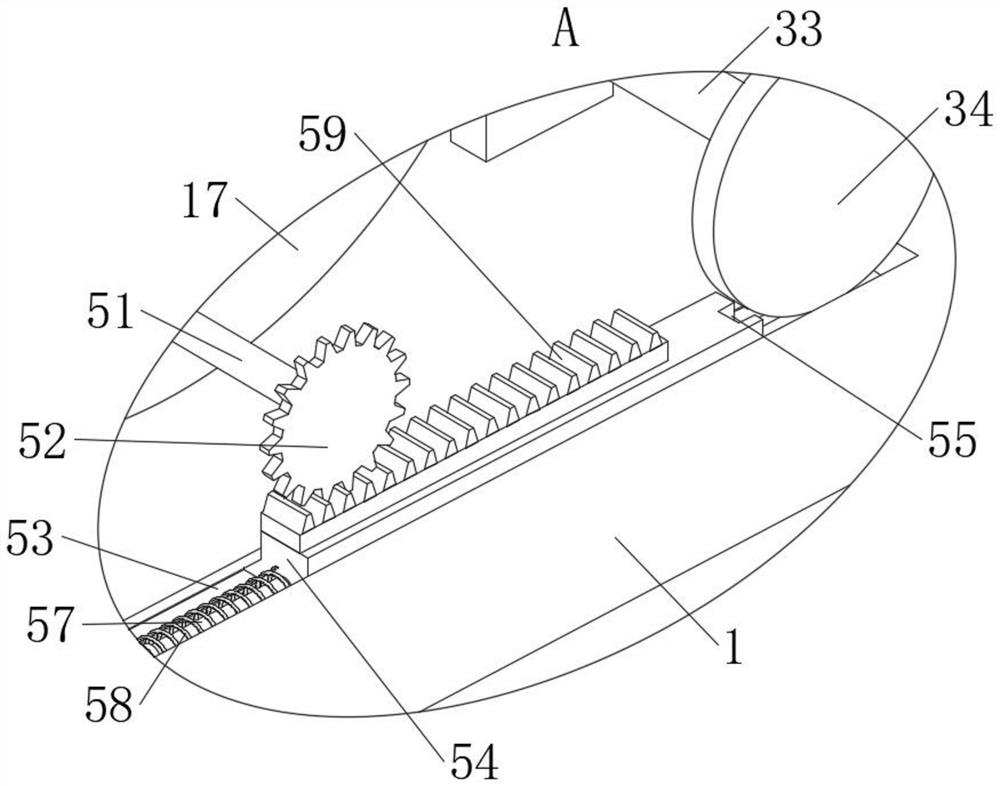

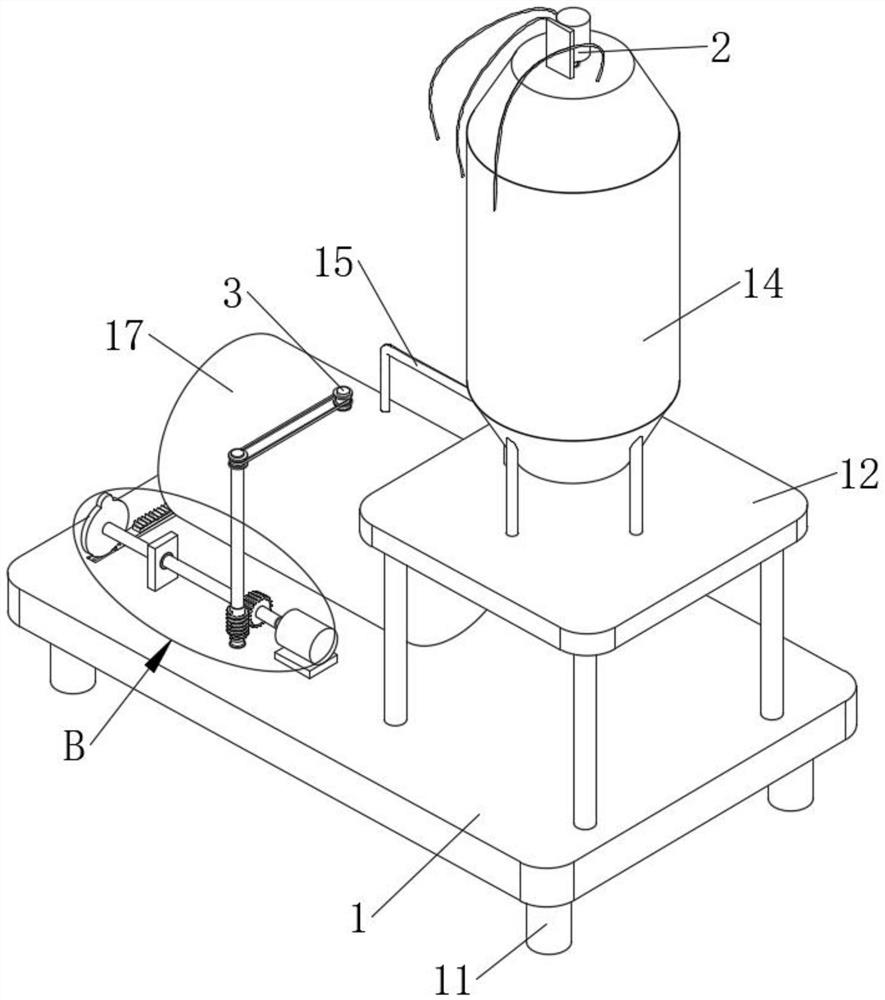

[0039] As an embodiment of the present invention, the cleaning mechanism 2 includes a first motor 21, and the surface of the fixed bed reactor body 14 is rotatably connected with a first rotating rod 23. By turning on the first motor 21, the first motor 21 can drive the first A rotating rod 23 rotates, the drive output end of the first motor 21 is fixedly connected with the upper end of the first rotating rod 23, and the outer wall of the first rotating rod 23 is symmetrically evenly distributed and fixedly connected with the first connecting rod 24, and the first connecting rod 24 One end is fixedly connected with a first scraper 25, the first rotating rod 23 can drive the first connecting rod 24 and the first scraper 25 to rotate, the first scraper 25 can scrape off the coking on the upper and lower inner walls of the fixed bed reactor body 14, One side of the first scraper 25 is in movable contact with the inner wall of the fixed bed reactor body 14, and the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com