Oil gas recovery processing system and oil gas recovery processing method

A recovery treatment and recovery system technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of large fire and explosion risks, large fire distances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

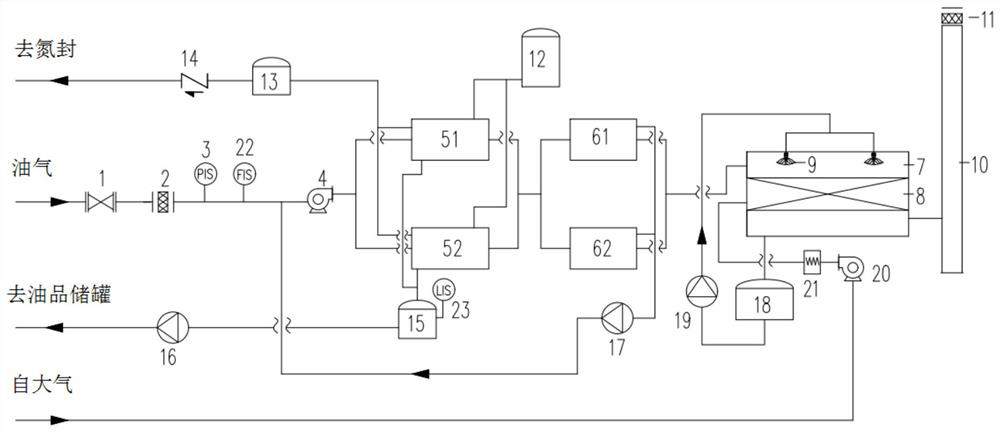

[0029] The invention provides an oil gas recovery and treatment system, which comprises a cryogenic recovery system, an adsorption homogenization system and a biological catalytic oxidation system which are sequentially connected by pipelines.

[0030] The front end of the cryogenic recovery system is connected to the oil and gas pipeline. On the oil and gas pipeline along the air flow direction, a stop valve 1, a flame arrester 1, a pressure sensor 3, an oil and gas flow meter 22 and an oil and gas blower 4 are arranged in sequence. The pressure sensor 3 is interlocked with the speed of the oil-gas blower 4 . The oil-gas blower 4 is a frequency conversion explosion-proof fan. The speed of the oil-gas blower 4 is adjusted by frequency conversion according to the intake pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com