Simple construction art coating as well as preparation method and application thereof

A kind of art paint, a simple technology, applied in the direction of anti-corrosion paint, coating, etc., can solve the problems of limitation, achieve the effect of improving anti-corrosion performance, long-lasting anti-corrosion performance, good decoration and beautification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example provides the preparation of an acrylic acid copolymer.

[0040] Step 1: Mix acrylic acid and silane coupling agent KH570 according to the molar ratio of 15:4, heat to 60°C under anhydrous conditions, add dropwise 1% potassium persulfate accounting for the total weight of the reaction solution, and react for 6 hours;

[0041] Step 2: Take the liquid after the reaction in step 1, add acrylic acid isocyanate according to the molar ratio of acrylic acid and acrylic isocyanate is 15:3, add 1% dibutyltin dilaurate to the total weight of the reaction liquid, and react under anhydrous conditions at 50°C 15 hours;

[0042] Step 3: Take the liquid after the reaction in step 3, add Cathone according to the molar ratio of acrylic acid and Cathone as 15:2, heat to 60°C under anhydrous conditions, add dropwise 1% potassium persulfate accounting for the total weight of the reaction solution, React for 6 hours to get an acrylic acid copolymer;

Embodiment 2

[0044] This example provides the preparation of an acrylic acid copolymer.

[0045] The silane coupling agent KH570 in Example 1 was replaced by (4-vinylphenyl)trimethoxysilane, and the rest were the same as in Example 1.

[0046] This embodiment provides a simple construction art paint and its preparation method.

[0047] (1) The composition of simple construction art paint.

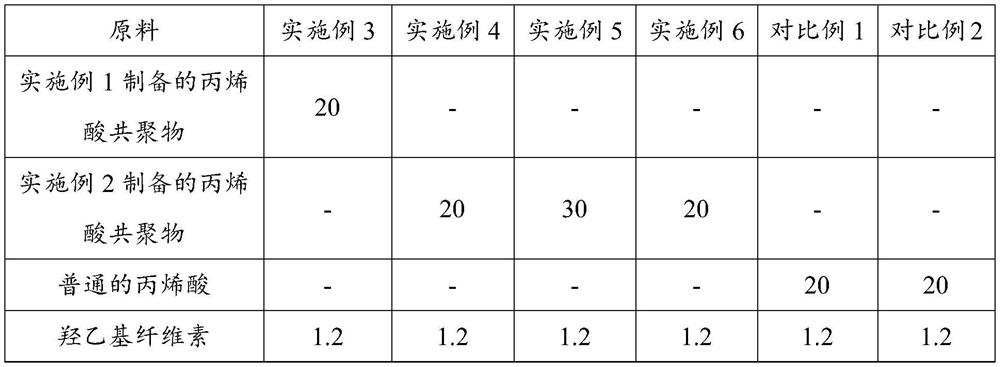

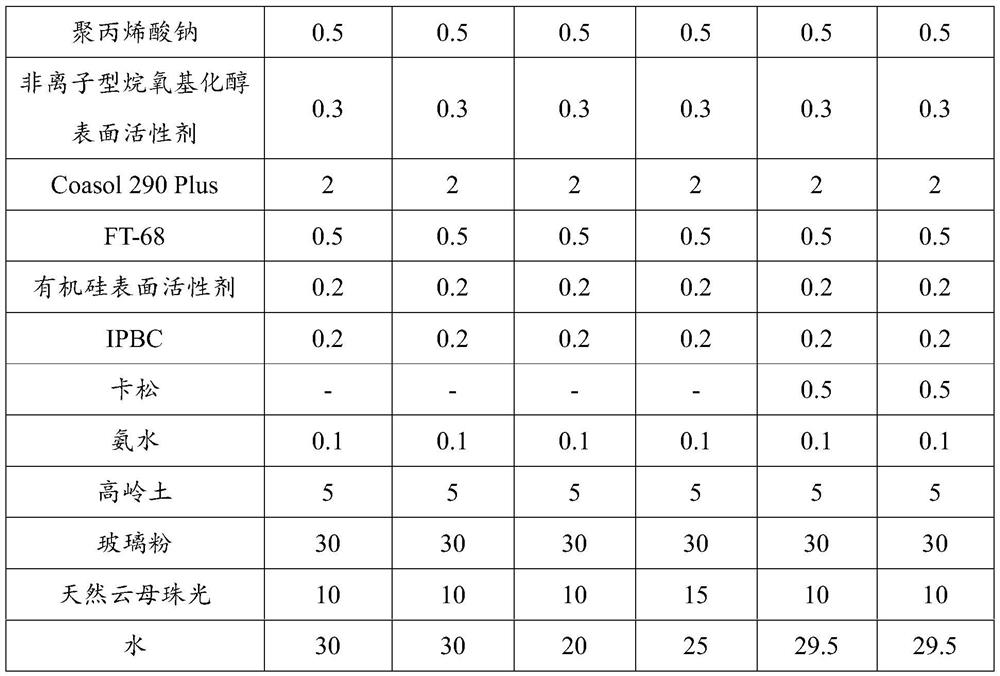

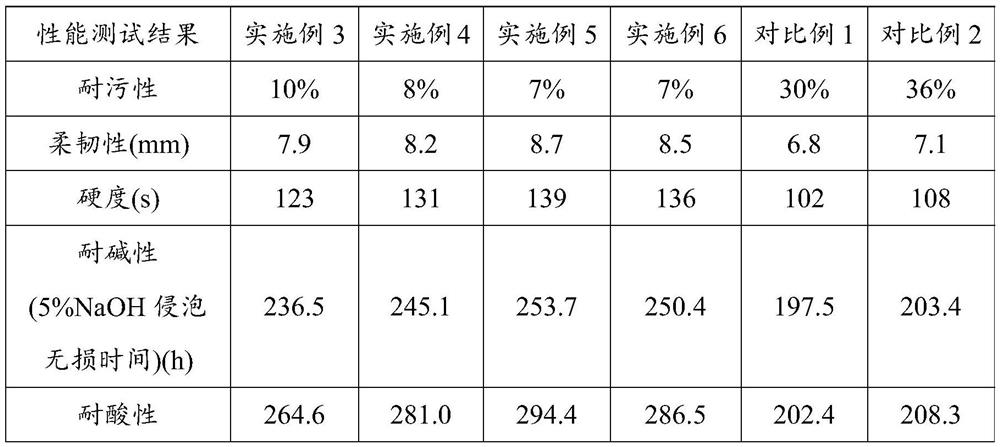

[0048] Table 1 The composition in parts by weight of the simple construction art paints of Examples 3-6 and Comparative Examples 1-2.

[0049]

[0050]

[0051] (2) The preparation of embodiment 3-6 simple construction art paint.

[0052] Step 1: Mix 5 parts by weight of sodium bicarbonate, 3 parts by weight of Tween-20, 12 parts by weight of sodium lauryl sulfate, 45 parts by weight of acrylic acid copolymer and 35 parts by weight of deionized water, and stir evenly at 50°C to obtain Acrylic copolymer emulsion.

[0053] Step 2: Mix water and 40% hydroxyethyl cellulose thoroughly for 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com