A kind of preparation method of 1,1-difluoro-2-iodoethylene

A technology of vinyl iodide and vinylidene fluoride, applied in the field of preparation of fluorine-containing elastomers, can solve the problems of high price of raw material ICl, difficult to obtain and store, complicated operating conditions, etc., and achieves overcoming safety risks, high price, low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

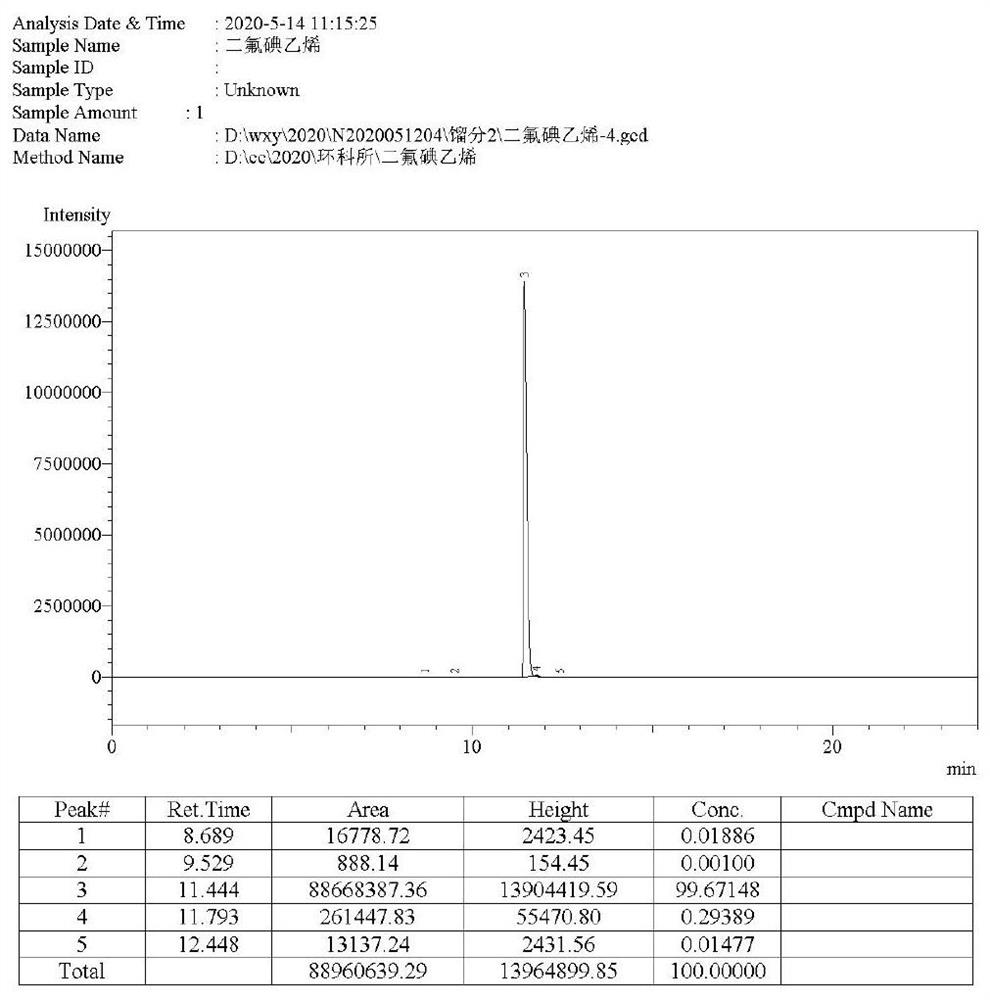

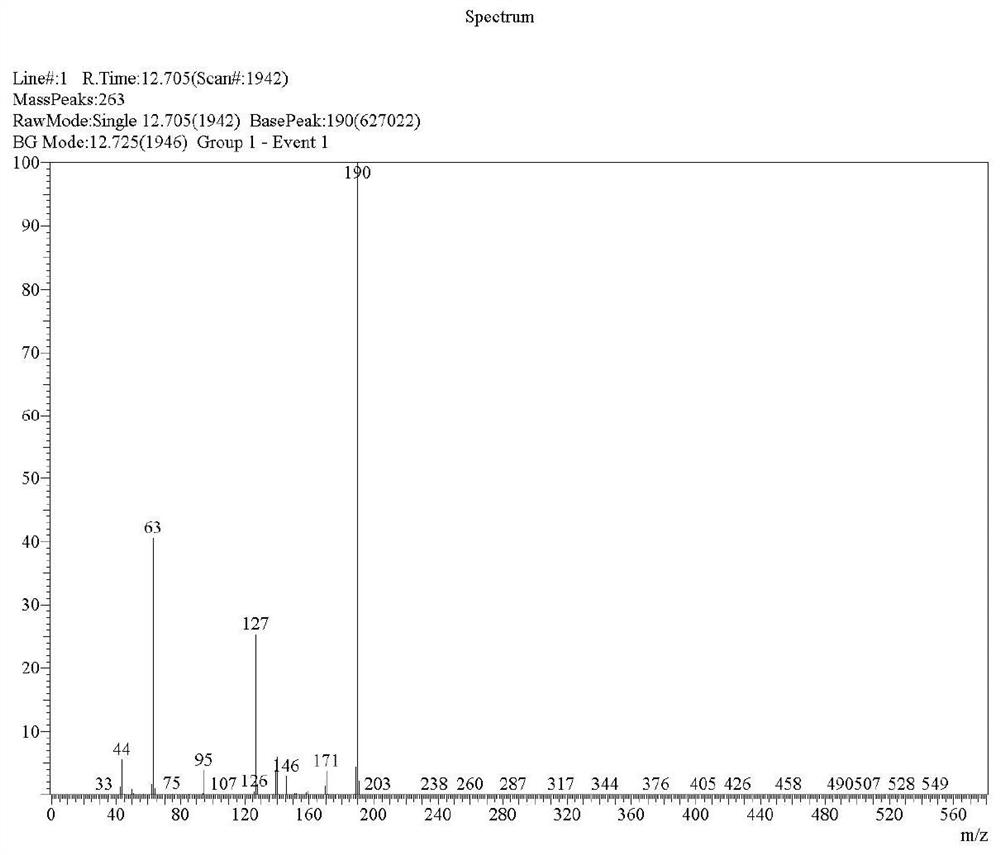

Image

Examples

Embodiment 1

[0033] (1) 316L material tubular reactor (Changsha Yuchuang Instrument Equipment Co., Ltd.) has an inner diameter of 5cm, a wall thickness of 8mm, and a tube length of 120cm. The effective height of the glass filler filled inside is 100cm, the particle size of the filler is 2mm, and the effective filler at the entrance is 30cm. As the raw material preheating section, the remaining 70cm of effective packing is used as the reaction section. The reactor is controlled by three-stage electric heating to control the temperature of the preheating section to 60°C and the temperature of the reaction section to 60°C. Control vinylidene fluoride with a flow rate of 640g / h (10mol / h) and chlorine gas into the tubular reactor with a flow rate of 710g / h (10mol / h) through a mass flowmeter, and the reaction product is condensed through a condenser, and the crude product 1,2 -Dichloro-1,1-difluoroethane was condensed into the crude product receiving bottle, and the tail gas was absorbed by 30wt...

Embodiment 2

[0037] (1) Hastelloy tubular reactor (Changsha Yuchuang Instrument Equipment Co., Ltd.) has an inner diameter of 5cm, a wall thickness of 8mm, and a tube length of 120cm. The effective height of the glass filler filled inside is 100cm, and the particle size of the filler is 2mm. 30cm is used as the raw material preheating section, and the remaining 70cm of effective packing is used as the reaction section. The reactor is controlled by three-stage electric heating to control the temperature of the preheating section to 60°C and the temperature of the reaction section to 100°C. Vinylidene fluoride is controlled by a mass flow meter with a flow rate of 640g / h (10mol / h), and chlorine gas is simultaneously passed into the tubular reactor with a flow rate of 640g / h (9mol / h). The reaction product is condensed by a condenser, and the crude product 1,2 -Dichloro-1,1-difluoroethane was condensed into the crude product receiving bottle, and the tail gas was absorbed by 30wt% KOH aqueous ...

Embodiment 3

[0041] (1) 304 stainless steel tubular reactor (Changsha Yuchuang Instrument Equipment Co., Ltd.) has an inner diameter of 5cm, a wall thickness of 8mm, and a tube length of 120cm. The effective height of the glass filler filled inside is 100cm, the particle size of the filler is 2mm, and the effective filler at the entrance is 30cm. , as the raw material preheating section, and the remaining 70cm of effective packing is used as the reaction section. The reactor is controlled by three-stage electric heating to control the temperature of the preheating section to 60°C and the temperature of the reaction section to 130°C. Control vinylidene fluoride with flow rate 640g / h (10mol / h) by mass flow meter, chlorine gas is passed in the tubular reactor simultaneously with flow rate 674.5g / h (9.5mol / h), reaction product is condensed by condenser, crude product 1 , 2-dichloro-1,1-difluoroethane was condensed into the crude product receiving bottle, and the tail gas was absorbed by 30wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com