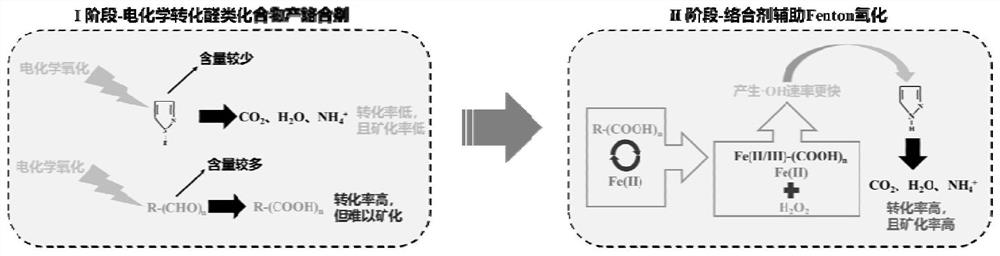

An electrochemical oxidation-assisted Fenton oxidation method for the treatment of aldehyde chemical industry wastewater

A technology for chemical wastewater and Fenton oxidation, applied in chemical instruments and methods, special compound water treatment, water/sewage treatment, etc., to reduce the dosage, improve the utilization rate of iron ions, and improve the efficiency of Fenton oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, the wastewater to be treated is self-prepared simulated wastewater, and a 500 mg / L glyoxal solution is prepared, and 500 mL is taken as the treated wastewater, and 50 mg / L pyrazole and 0.05 mol of anhydrous sodium sulfate are added. Among them, pyrazole is a refractory target pollutant.

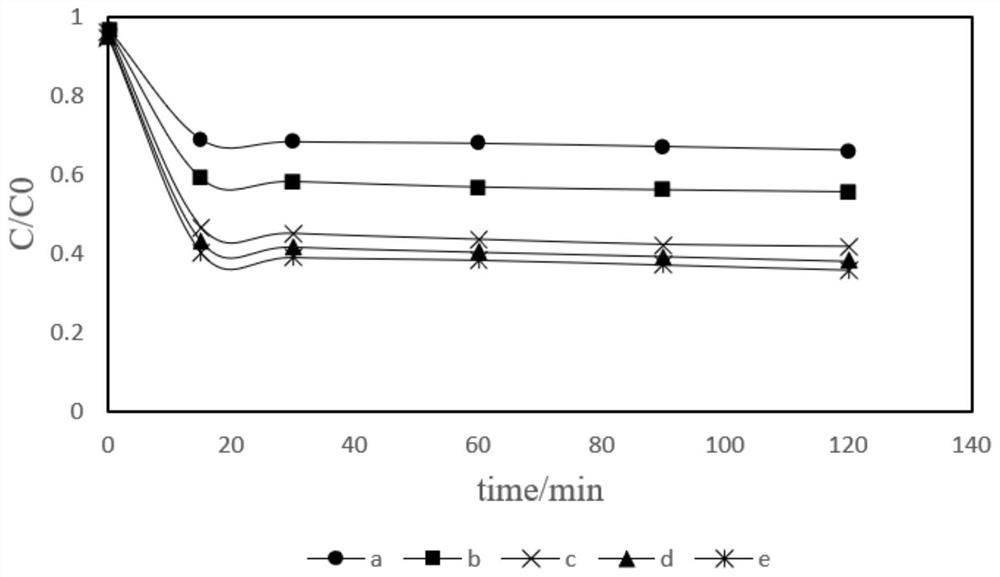

[0053] This embodiment adopts the coupled process of "electrochemical oxidation + Fenton oxidation". Prepare five copies of the same simulated wastewater above, adjust the pH of the wastewater to 6.5, and perform electrochemical assisted oxidation for 0.5, 1, 2, 3, and 4 hours respectively. The electrode material in the electrochemical assisted oxidation unit is a plate electrode, and the anode material is It is a ruthenium dioxide-coated plate electrode, and the cathode material is a stainless steel plate electrode. At this stage, the control current density is 3.5~6.5mA / cm 2 , Constant current treatment of wastewater, turn off the power. Then, the tail water af...

Embodiment 2

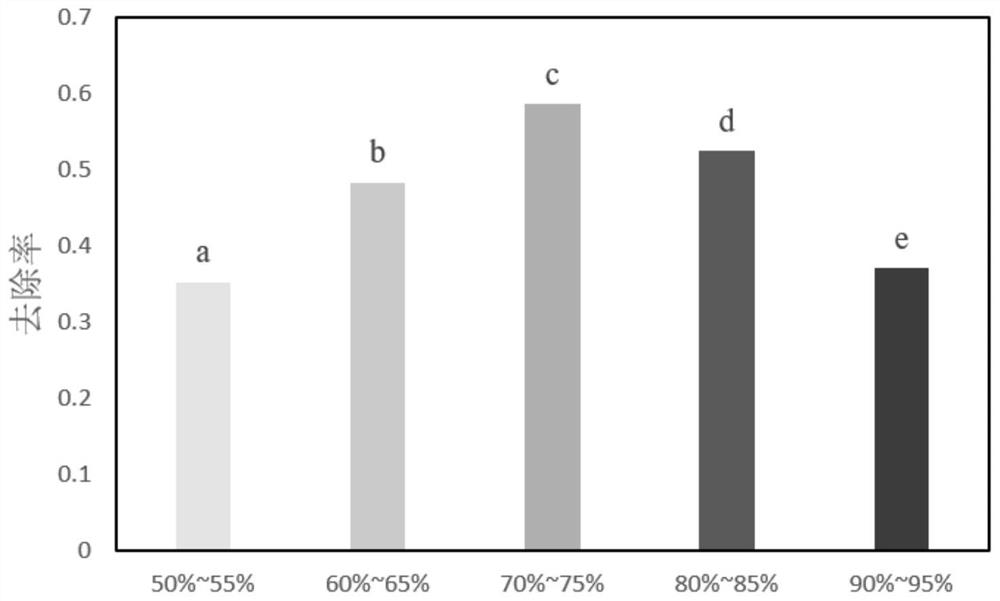

[0058] The wastewater treatment of this embodiment continues to use simulated wastewater, prepare five parts of 500mL 50mg / L pyrazole solutions, add different amounts of oxalic acid (see its dosage and Fe 2+ ratio), stir to dissolve, add FeSO 4 ·7H 2 O, add H after about 5 minutes until the ferrous ions are completely dissolved and complexed 2 o 2 , so that simulated wastewater COD and H 2 o 2 The mass ratio is 1:0.8, iron (II) and H 2 o 2 The molar ratio is about 1:10. Fe in wastewater a 2+ with C 2 h 2 o 4 The molar ratio is about 1:0.25 (Fe 2+ The molar ratio to carboxyl group is about 1:0.5), Fe in wastewater b 2+ with C 2 h 2 o 4 The molar ratio is about 1:0.5 (Fe 2+ The molar ratio to the carboxyl group is about 1:1), Fe in the wastewater c 2+ with C 2 h 2 o 4 The molar ratio is about 1:1 (Fe 2+ The molar ratio to carboxyl group is about 1:2), Fe in wastewater d 2+ with C 2 h 2 o 4 The molar ratio is about 1:1.5 (Fe 2+ The molar ratio to carboxy...

Embodiment 3

[0063] In this example, the quality of the industrial tail water to be treated is the tail water discharged during the production process of a chemical fiber enterprise, the COD content is 6000-8000 mg / L, and the COD contributed by aldehyde organic molecules is 55%-60%, and the pH value of the wastewater is 9-10, the main pollutants are acetaldehyde, triethylene glycol, PTA, EG and other pollutants, and also include pyrrole, indole, pyrazole, and other refractory nitrogen-containing heterocyclic compounds.

[0064] This embodiment adopts the coupled process of "electrochemical oxidation + Fenton oxidation".

[0065] In this embodiment, the electrode material in the electrochemical assisted oxidation unit is a plate electrode, the anode material is a ruthenium dioxide coated plate electrode, and the cathode material is a stainless steel plate electrode. At this stage, the control current density is 3.5~6.5mA / cm 2 , The wastewater is treated with a constant flow, the pH value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com