Device and method for feeding and discharging of LNG cylinders in processing area

A processing area, material feeding and discharging technology, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problem that the workpiece enters the processing area with a long rotation time period, reduces production efficiency and profit output, and is not suitable for LNG cylinder transfer. and other problems to achieve the effect of reducing floor space, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

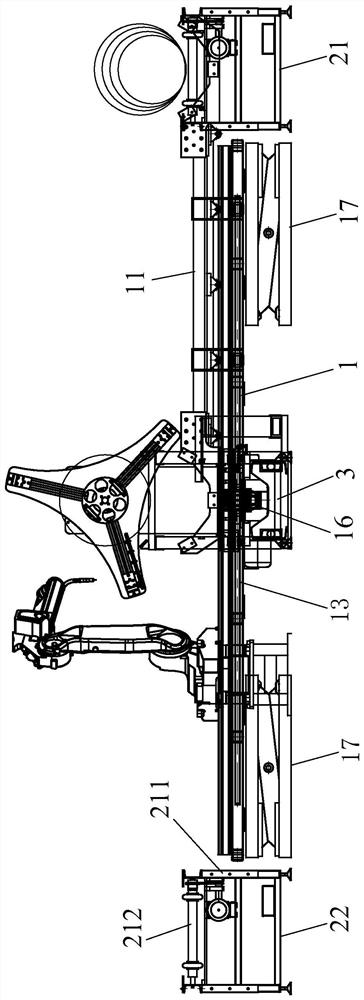

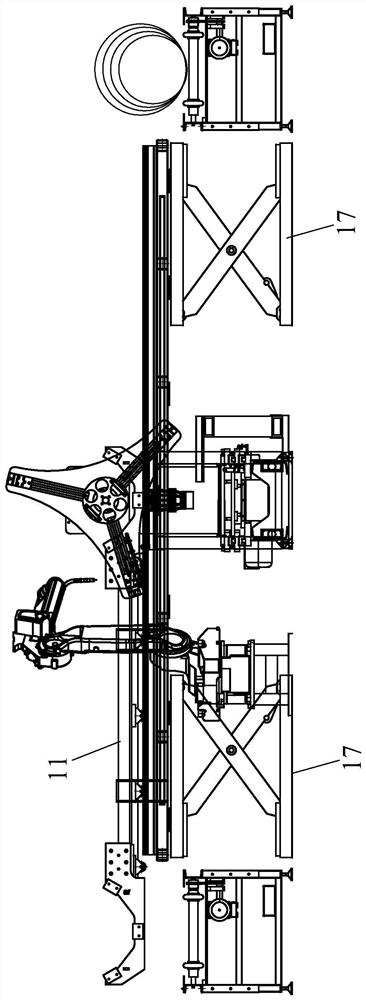

[0053] see Figure 1 to Figure 7 .

[0054] This embodiment 1 discloses a device for feeding and discharging LNG gas cylinders in the circular seam welding processing area, including a claw-type lifting and translation mechanism 1, a roller conveyor line 21 for feeding, and a roller conveyor line 22 for discharging , and two support frames 3 arranged at the processing station for supporting the LNG cylinder. The roller conveying line 21 for feeding and the roller conveying line 22 for discharging are arranged in parallel on both sides of the processing station; Between the conveying lines 22, and located at the processing station, it is used to feed the support frame 3 on the roller conveying line 21 to the support frame 3, and to unload the LNG gas cylinder from the support frame 3 to the On the roller conveying line 22 for discharging.

[0055] In the first embodiment, the claw-type lifting and translation mechanism 1 includes a claw-type manipulator 11 , a support platfo...

Embodiment 2

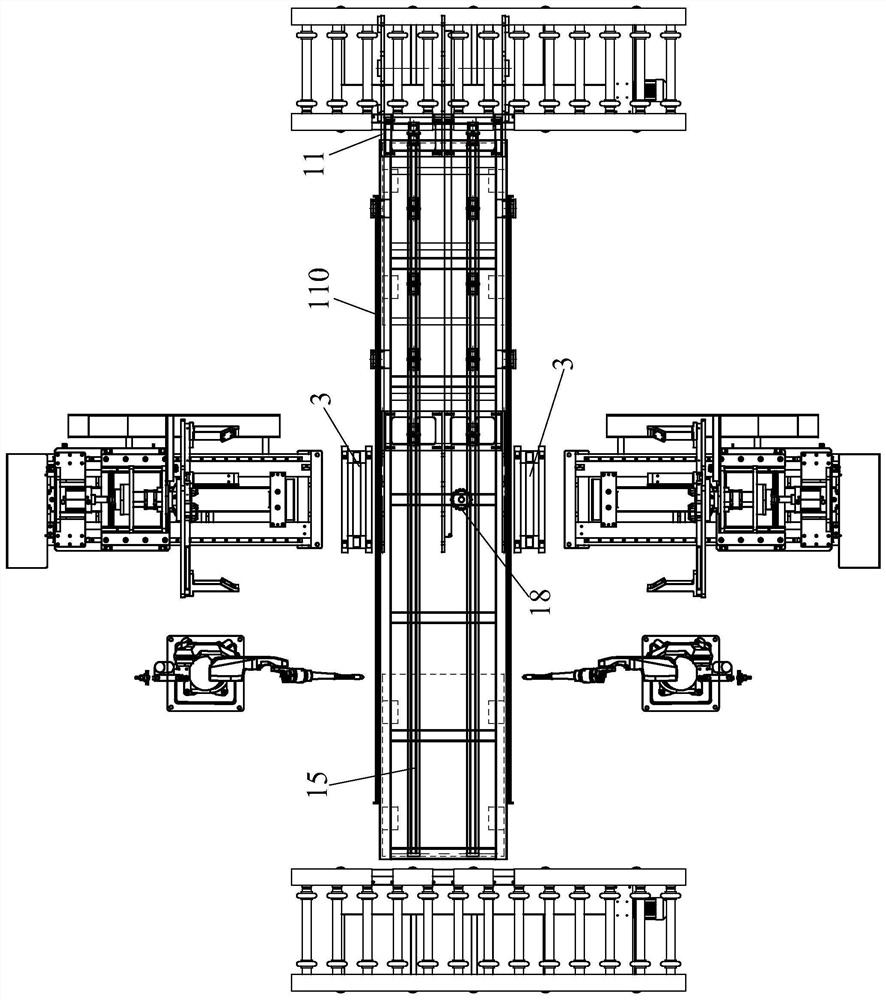

[0064] see Figure 8 to Figure 10 .

[0065] Another device for feeding and discharging LNG gas cylinders in the processing area is disclosed in Embodiment 2, which includes a claw-type jacking translation mechanism 1, a jacking mechanism 4 for LNG gas cylinders, a roller conveyor line 21 for feeding, and a A roller conveying line 22 is used for the material, and at least two support frames 3 arranged at the processing station for supporting the LNG cylinder. The roller conveying line 21 for feeding and the roller conveying line 22 for discharging are arranged in parallel on both sides of the processing station; Frame 211 and a row of conveying rollers 212 installed on the mounting frame 211; the claw-type jacking translation mechanism 1 is arranged between the roller conveying line 21 for feeding and the roller conveying line 22 for discharging, and is located at the processing station It is used to load the support frame 3 on the roller conveyor line 21 for feeding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com