3D printing layering processing method, device and equipment and storage medium

A 3D printing and processing method technology, applied in the field of 3D printing, can solve problems such as the inability to balance printing quality and printing efficiency, and the fixed thickness of slice layers, so as to ensure printing quality and printing efficiency, good detail performance, and increase work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An embodiment of the present invention provides a 3D printing layering method, which is suitable for layering a three-dimensional model of a target object in 3D printing. In the 3D model of the target object, the gradient of the edge pixels reflects the degree of color change on the surface of the object, and the gradient of the edge pixels in the stacking direction is used to determine the layer thickness.

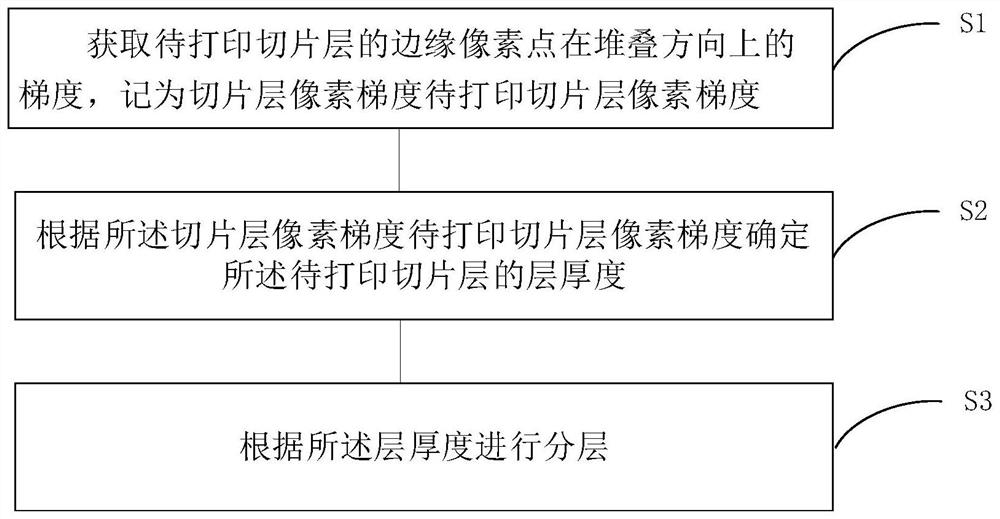

[0045] See figure 1 , the method specifically includes the following steps:

[0046] S1: Obtain the gradient of the edge pixels of the slice layer to be printed in the stacking direction, and record it as the pixel gradient of the slice layer to be printed;

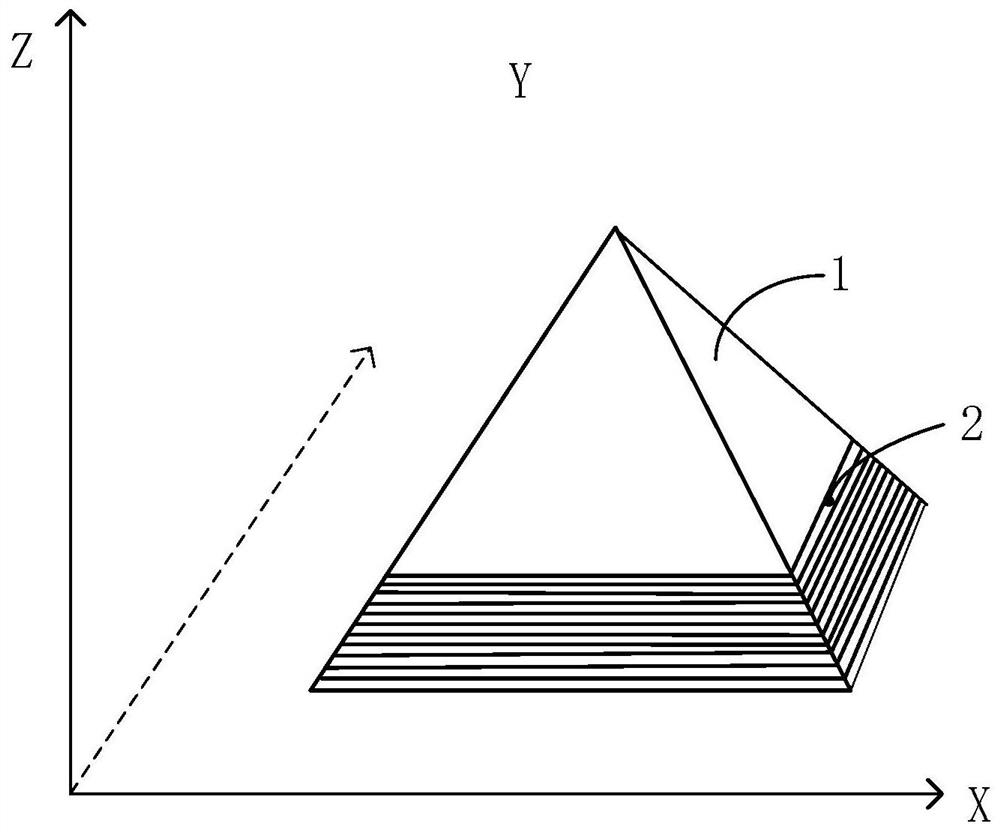

[0047] Such as figure 2 As shown, the coordinate axes of the coordinate system where the 3D model 1 of the target object to be printed are located are x, y, z, and the direction of the z axis is the stacking direction of the slice layers when 3D printing the 3D model of the target object.

[0048] For a ce...

Embodiment 2

[0096] The embodiment of the present invention also provides a 3D printing method, the specific printing steps are as follows:

[0097] S10: Obtain the layer thickness of the slice layer to be printed through the 3D slice processing method described in Embodiment 1;

[0098]S11: Determine the amount of consumables required for printing the slice layer to be printed according to the layer thickness of the slice layer to be printed;

[0099] S12: Print the slice layer to be printed according to the layer thickness of the slice layer to be printed and the amount of consumables required for printing the slice layer to be printed.

[0100] The amount of consumables required for slice layers with different layer thicknesses is different, so it is necessary to calculate the required amount of consumables according to the layer thickness. Preferably, step S11 further includes:

[0101] S111: Obtain the amount of consumables required by the currently printed slice layer;

[0102] S11...

Embodiment 3

[0108] see Figure 4 , the embodiment of the present invention provides a 3D printing layer processing device 200, the device 200 includes:

[0109] The gradient acquisition module 201 is used to acquire the gradient of the edge pixel points of the slice layer to be printed in the stacking direction, which is recorded as the pixel gradient of the slice layer to be printed;

[0110] A layer thickness acquisition module 202, configured to determine the layer thickness of the slice layer to be printed according to the pixel gradient of the slice layer to be printed;

[0111] The slice layer module 203 is configured to perform layering according to the layer thickness.

[0112] Further, the gradient acquisition module 201 also includes:

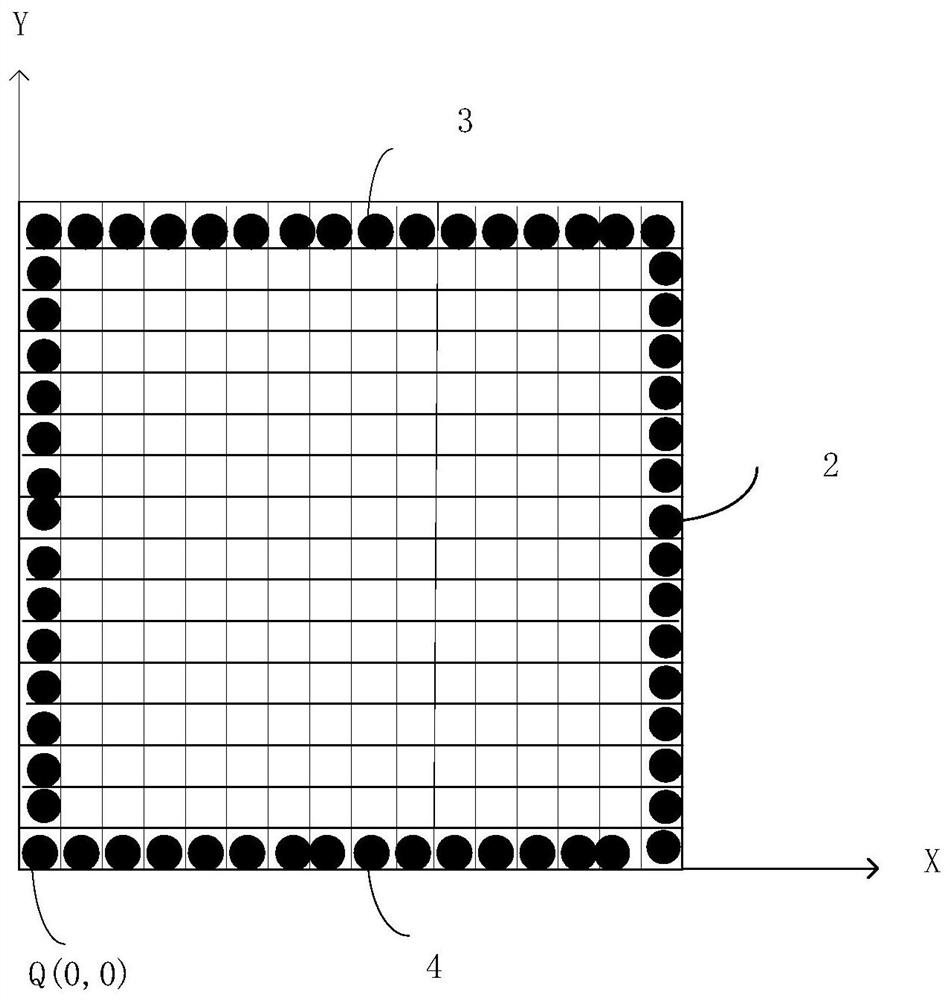

[0113] a coordinate acquisition unit, configured to acquire the coordinate values of the edge pixel points;

[0114] a pixel value acquisition unit, configured to acquire the pixel value of the edge pixel point;

[0115] A gradient acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com