a co 2 Method for Directly Fabricating Sinusoidal Phase Grating on Fused Silica Surface by Laser

A phase grating and fused silica technology, which is applied in laser welding equipment, welding equipment, diffraction gratings, etc., can solve the problem that the laser cannot directly prepare fused silica sinusoidal phase grating, etc., and achieves convenient and flexible preparation, easy implementation, and high laser damage threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] like Figure 1-Figure 5 shown, a CO 2 The method of directly preparing sinusoidal phase grating on the surface of fused silica by laser is carried out according to the following steps:

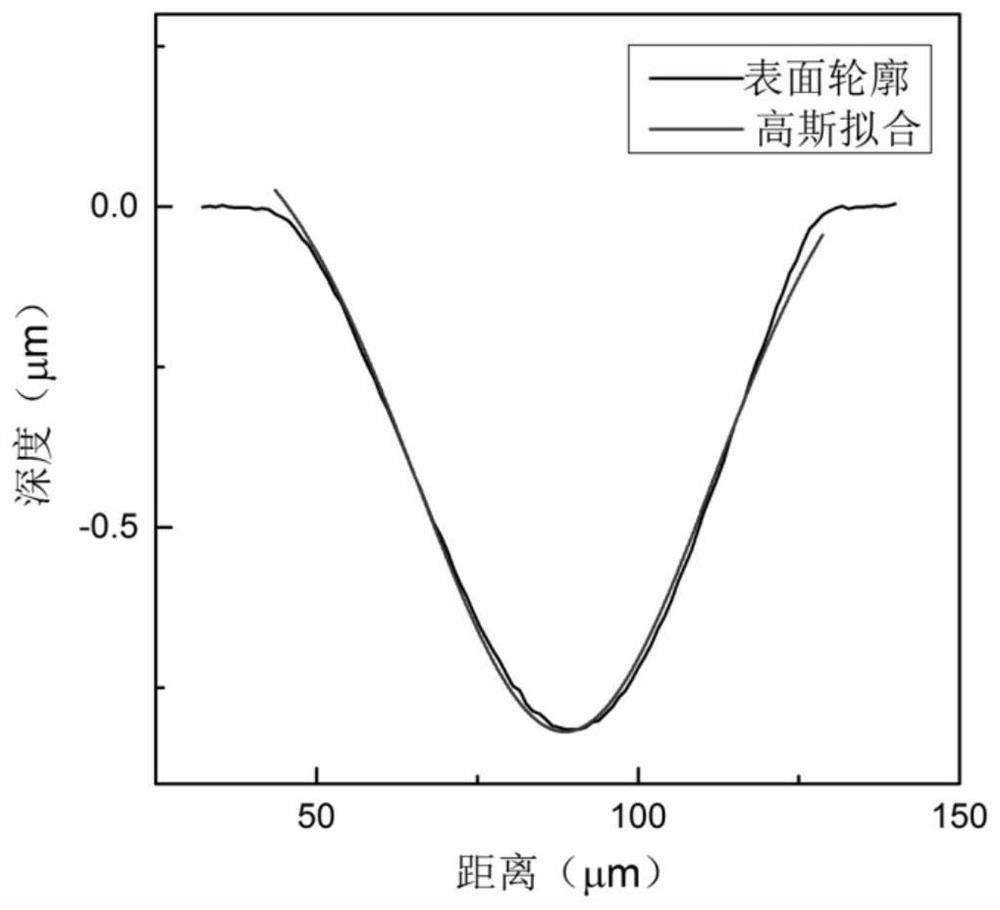

[0039] S1. The Gaussian ablation pit is a linear structure, and the Gaussian ablation pits of each linear structure together form a one-dimensional sinusoidal phase grating, and the CO is set accordingly. 2 The parameters of the laser: the power of the laser is 56W, the continuous laser output, the diameter of the focused spot size is 120μm, and the scanning speed is 3m / s.

[0040] S2, CO 2 The laser emits continuous CO 2 The laser beam is focused and irradiated on the surface of the fused silica along a straight path, and a Gaussian ablation pit with a smooth surface and a linear structure is formed on the surface of the fused silica.

[0041] S3. Use a microscope and a step meter to check whether the surface morphology and contour of the linearly structured Gaussian ablation pits fo...

Embodiment 2

[0047] See Figure 6-Figure 9 , a CO 2 The method of directly preparing sinusoidal phase grating on the surface of fused silica by laser is carried out according to the following steps:

[0048] S1. The Gaussian ablation pit is a point-like structure, each Gaussian ablation pit is distributed in a matrix, and there are four Gaussian ablation pits arranged in a square evenly distributed around each Gaussian ablation pit. Together to form a two-dimensional sinusoidal phase grating, according to which the CO is set 2 The parameters of the laser: the power of the laser is 200W, the pulse width is 20μs, the frequency is 200Hz, the diameter of the focusing spot is 220μm, and the scanning speed is 24mm / s.

[0049] S2, CO 2 The laser emits a single pulse of CO 2 The laser beam is focused and irradiated on the surface of the fused silica to ablate the surface of the fused silica to form a Gaussian ablation pit with a smooth surface and a matrix distribution.

[0050] S3. Use a mic...

Embodiment 3

[0056] See Figure 10-Figure 13 , a CO 2 The method of directly preparing sinusoidal phase grating on the surface of fused silica by laser is carried out according to the following steps:

[0057] S1. The Gaussian ablation pit is a point-like structure, each Gaussian ablation pit is distributed in a two-dimensional array, and there are six Gaussian ablation pits arranged in a regular hexagon evenly distributed around each Gaussian ablation pit etched pits, which together form a two-dimensional sinusoidal phase grating, according to which the CO is set 2 The parameters of the laser: the power of the laser is 200W, the pulse width is 20μs, the frequency is 200Hz, the diameter of the focusing spot is 220μm, and the scanning speed is 24mm / s.

[0058] S2, CO 2 The laser emits a single pulse of CO 2 The laser beam is focused and irradiated on the surface of the fused silica to ablate the surface of the fused silica to form a Gaussian ablation pit with a smooth surface and a matr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com